A preparation process for heat dissipation packaging of compact igbt modules

A preparation process, compact technology, applied in the field of heat dissipation packaging preparation process, can solve the problems affecting the normal use of IGBT, insulation package breakdown of IGBT module, IGBT high load work and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

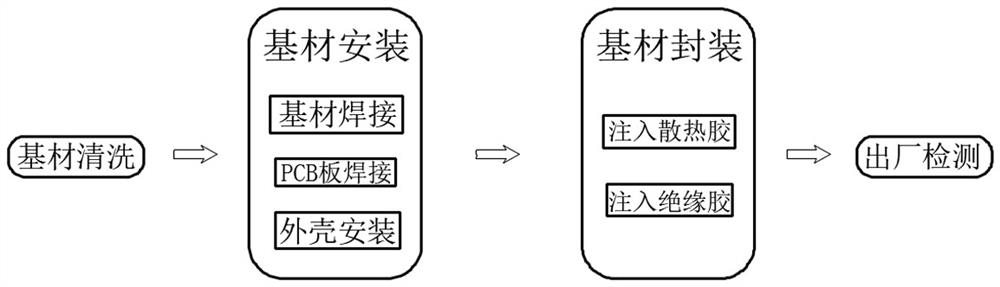

Method used

Image

Examples

Embodiment 1

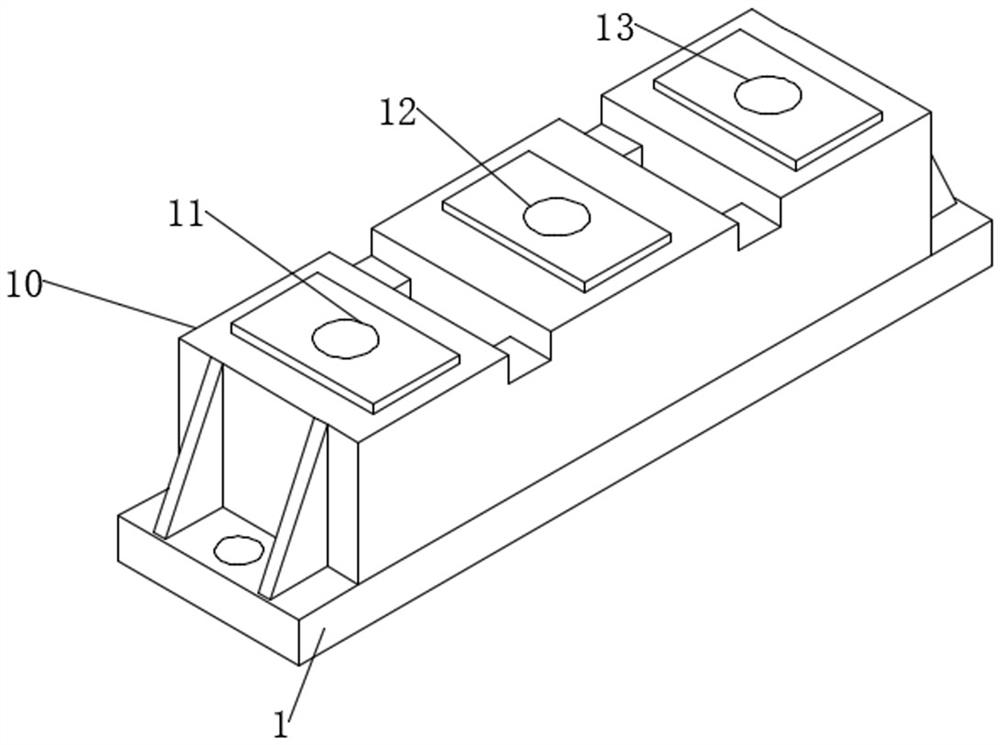

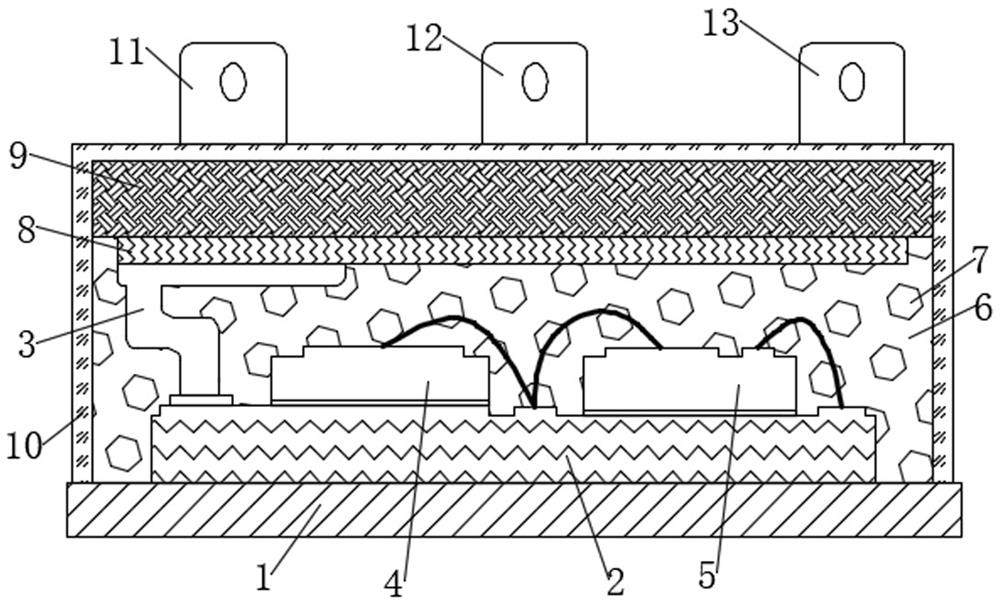

[0041] see Figure 1-2 , a preparation process for heat dissipation packaging of compact IGBT modules, including a substrate 1, the upper end of the substrate 1 is fixedly connected with an IGBT case 10 and a liner 2, an installation cavity is formed between the substrate 1 and the IGBT case 10, and the liner The board 2 is located in the installation cavity, and the upper end of the lining board 2 is fixedly connected with the busbar electrode 3, the FRD chip 4 and the IGBT chip 5 in order from left to right, and the FRD chip 4 and the IGBT chip 5 are electrically connected to the lining board 2. The section of the busbar electrode 3 away from the liner 2 is fixedly connected to the PCB 8, and the installation cavity is filled with silica gel 6 and cycloresin 9. On the upper side, the upper end of the IGBT case 10 is connected to the gate 11 , emitter 12 and collector 13 , and the gate 11 , emitter 12 and collector 13 are all electrically connected to the PCB 8 .

[0042] A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com