Nickel-zinc battery

A nickel-zinc battery and zinc negative charge technology, which is applied in the direction of nickel storage battery, alkaline storage battery, aqueous electrolyte, etc., can solve the problems of nickel-zinc battery polluting the environment and failing to meet the requirements of the power supply field, and achieve low cost and reduce zinc dendrites formation, elimination of reduced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

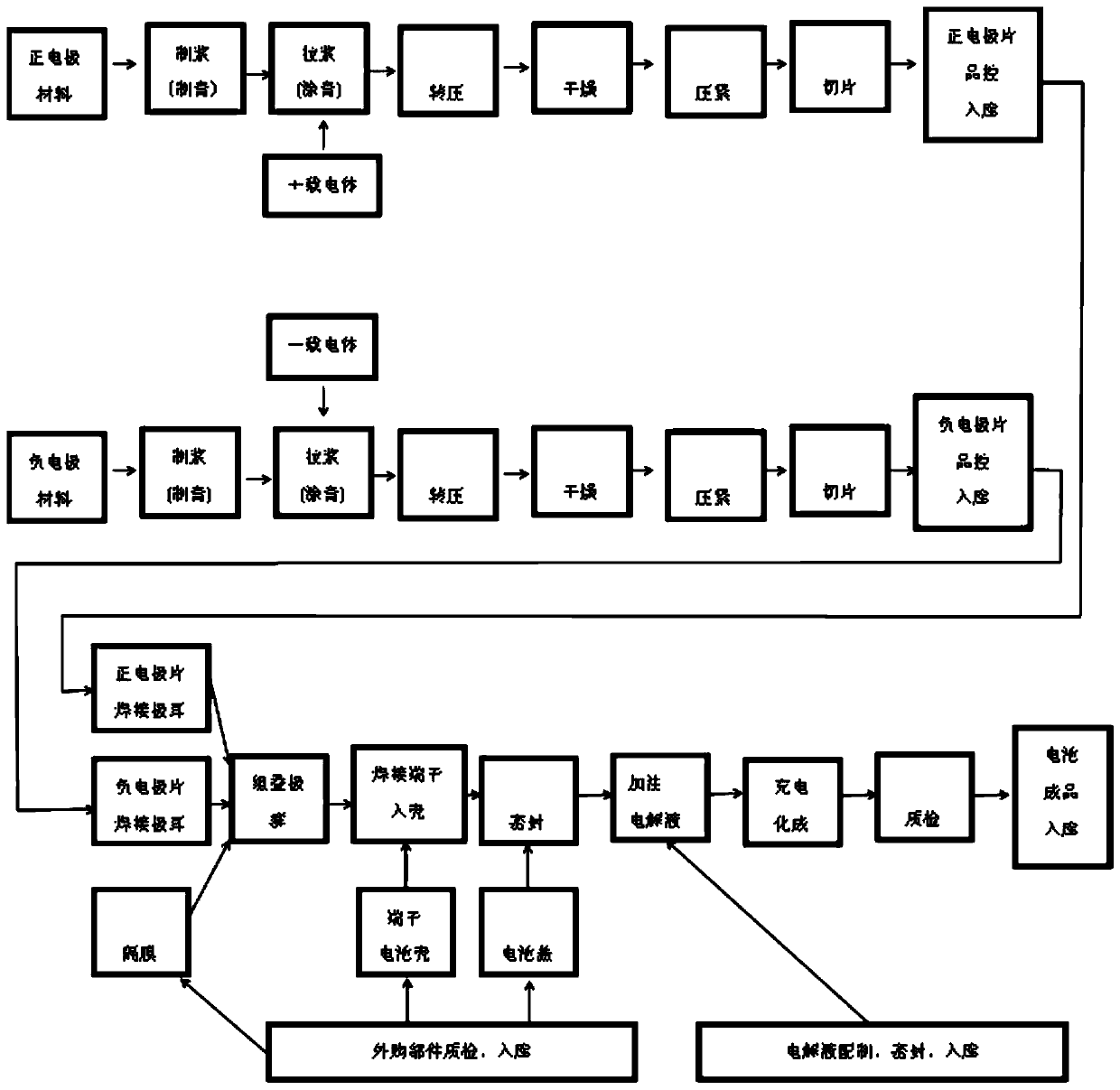

[0027] The zinc-nickel battery is an alkaline accumulator composed of a zinc negative electrode, a nickel positive electrode, an electrolyte, a diaphragm and a container. Its preparation process is as follows figure 1 shown.

[0028] The material weight ratio of the zinc negative electrode slurry is selected from one of the following formulas:

[0029] Formula 1: zinc oxide 70%-95%; graphene 0.1%-5%; magnesium oxide 0.1%-5%; aluminum oxide 0.01%-1%; bismuth oxide 0.01%-5%; indium oxide 0.01%-1% ;Lead oxide 0.%~1%; Sodium phosphate 0%~2%; Sodium borate 0%~5%; PTFE0.1%~6%; CMC0.1%~2%; HEC0.1%~2%; Appropriate amount of solution.

[0030] Formula 2: zinc oxide 80-95%; zinc powder 0.1%-10%; calcium hydroxide 0.1%-20%; bismuth oxide 0.01%-5%; indium oxide 0.01%-1%; carbon black 0.1%-5% ; Lead oxide 0-1%; PTFE 0.1%-6%; CMC 0.1%-2%; HEC 0.1%-2%; appropriate amount of solution.

[0031] Formula 3: zinc oxide 50%~95%; calcium zincate 0%~50%; magnesium oxide 0.1%~5%; bismuth oxide 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com