Bactericidal algicide as well as preparation method and application thereof

A technology of bactericidal algicide and penetrant, applied in herbicides and algicides, botanical equipment and methods, applications, etc. Short time and other problems, to achieve the effect of strengthening the sterilization and algae killing effect, enhancing the sterilization and algae killing power, and improving the long-term effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

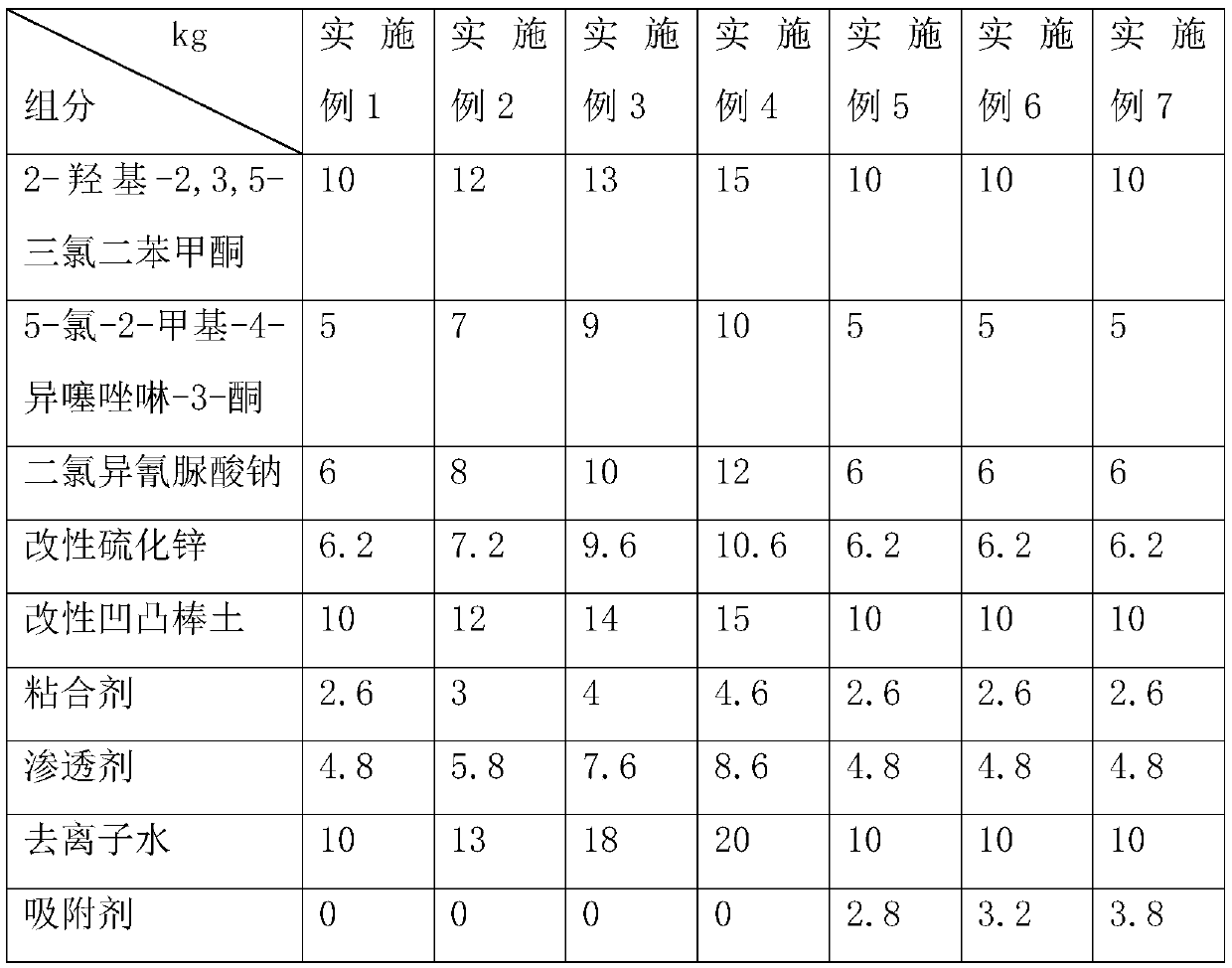

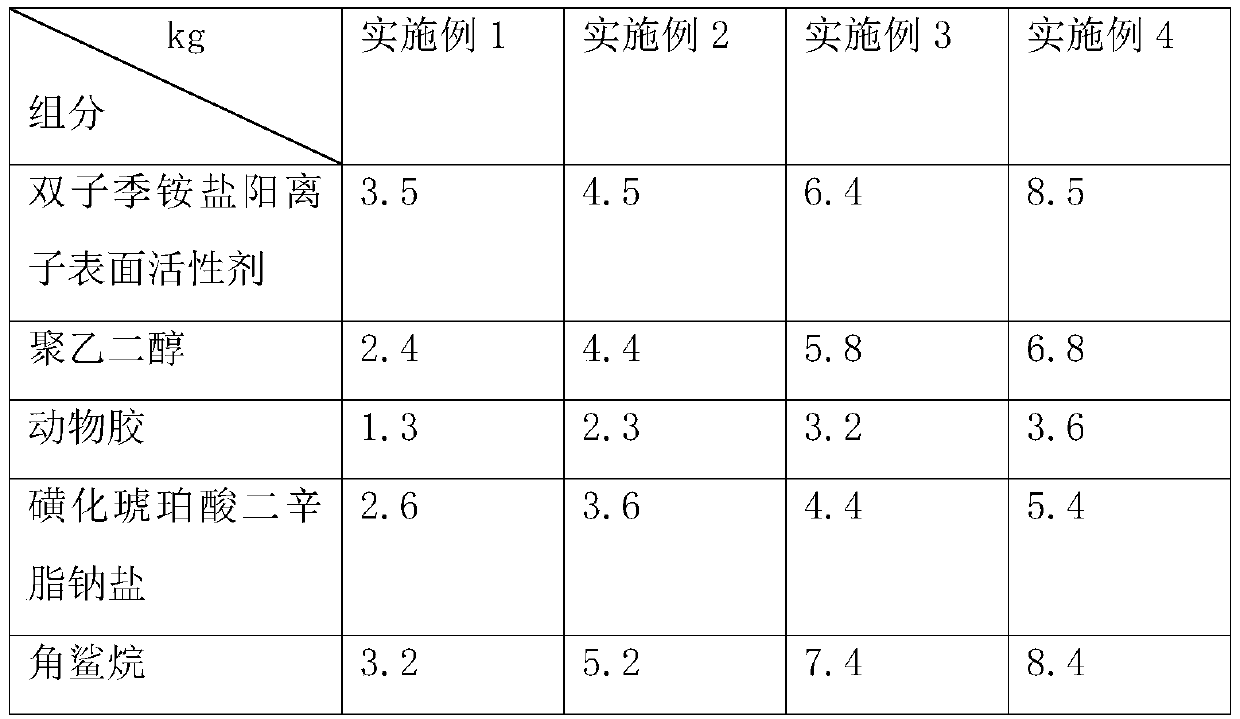

Method used

Image

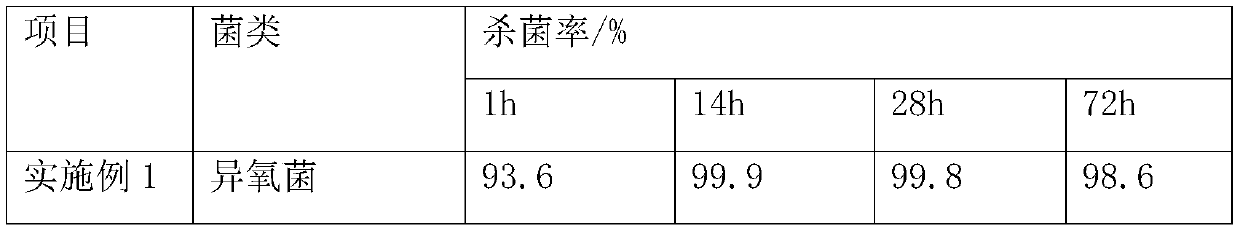

Examples

preparation example 1

[0044] Preparation Example 1: (1) Crush the attapulgite, pass a 20-mesh sieve, add 6 times its mass to a hydrochloric acid solution, stir at 80°C for 2h, centrifuge at 1500r / min for 15min, and wash with deionized water To neutral, dry at 100℃, the concentration of hydrochloric acid solution is 31%;

[0045] (2) Add phosphinic acid-based polyacrylic acid, hydroxyethylidene diphosphonic acid and polyacrylic acid to the resultant of step (1), mix uniformly and dry, to obtain modified attapulgite, attapulgite and phosphinic acid-based The mass ratio of polyacrylic acid, hydroxyethylidene diphosphonic acid and polyacrylic acid is 1:0.3:0.1:0.2.

preparation example 2

[0046] Preparation Example 2: (1) The attapulgite was crushed, passed through a 20-mesh sieve, added to a hydrochloric acid solution of 8 times its mass, stirred at 85°C for 1.5h, centrifuged at 1600r / min for 13min, and deionized water Wash to neutral, dry at 110℃, the concentration of hydrochloric acid solution is 31%;

[0047] (2) Add phosphinic acid-based polyacrylic acid, hydroxyethylidene diphosphonic acid and polyacrylic acid to the resultant of step (1), mix uniformly and dry, to obtain modified attapulgite, attapulgite and phosphinic acid-based The mass ratio of polyacrylic acid, hydroxyethylidene diphosphonic acid and polyacrylic acid is 1:0.4:0.2:0.3.

preparation example 3

[0048] Preparation Example 3: (1) The attapulgite was crushed, passed through a 20-mesh sieve, added to a hydrochloric acid solution of 10 times its mass, stirred at 90°C for 1 hour, centrifuged at 1800r / min for 10 minutes, and washed with deionized water To neutral, dry at 120℃, the concentration of hydrochloric acid solution is 31%;

[0049] (2) Add phosphinic acid-based polyacrylic acid, hydroxyethylidene diphosphonic acid and polyacrylic acid to the resultant of step (1), mix uniformly and dry, to obtain modified attapulgite, attapulgite and phosphinic acid-based The mass ratio of polyacrylic acid, hydroxyethylidene diphosphonic acid and polyacrylic acid is 1:0.5:0.3:0.4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com