Silicon carbide modified YAG:Ce fluorescent powder and preparation method thereof

A fluorescent powder and silicon carbide technology, applied in chemical instruments and methods, luminescent materials, climate sustainability, etc., can solve the problems of thermal stability and luminous efficiency, unfavorable white LED light source, etc., and achieve high thermal stability , the effect of high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

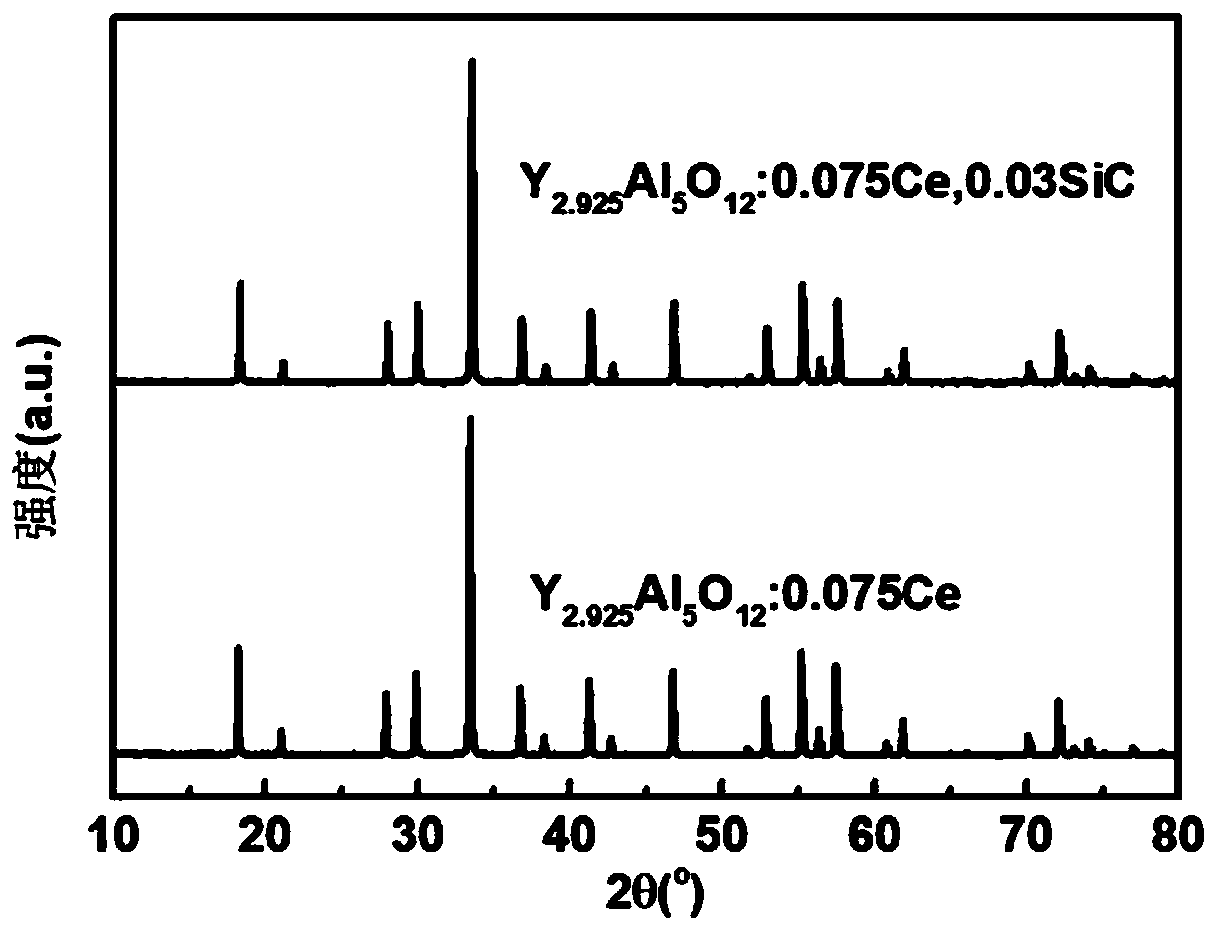

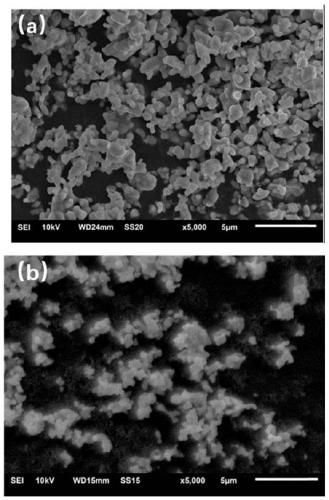

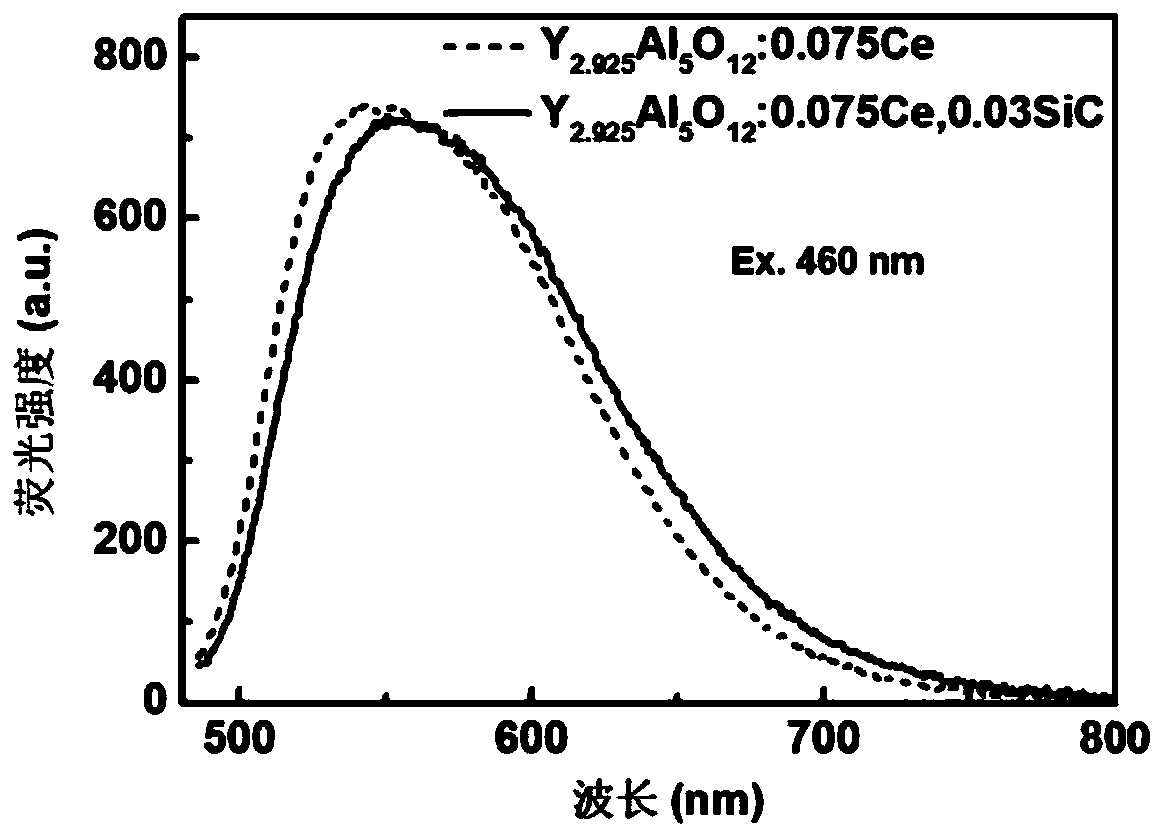

[0026] Example 1: Y 2.925 al 5 o 12 :0.075Ce,0.01SiC

[0027] (1) Set the target product Y 2.925 al 5 o 12 : 0.075Ce, 0.01SiC has a mass of 20 g, and Y is weighed according to the ratio of Y:Al:Ce:Si: 2.925:5:0.075:0.01 2 o 3 (99.99%), Al 2 o 3 (99.99%), CeO 2 (99.99%), SiC (99.9%) raw materials, using a planetary ball mill for 10-20 h;

[0028] (2) Put the precursor mixture obtained in step (1) into a high-purity alumina crucible, and then place it in a high-temperature tubular furnace. Under a reducing atmosphere, keep it at 1500 °C for 5 h, and the heating rate is 600 °C / h , the synthesized phosphor is naturally cooled with the furnace body;

[0029] (3) Take out the phosphor powder synthesized in step (2), put it into a beaker filled with deionized water, add concentrated hydrochloric acid with a mass fraction of 36%-38%, and the volume ratio of deionized water to concentrated hydrochloric acid is 10: 1. Stir at 100 °C for 20 min, let stand to separate layers, ...

Embodiment 2

[0030] Example 2: Y 2.925 al 5 o 12 :0.075Ce,0.03SiC

[0031] (1) Set the target product Y 2.925 al 5 o 12 : 0.075Ce, 0.03SiC has a mass of 20 g, and Y is weighed according to the ratio of Y:Al:Ce:Si: 2.925:5:0.075:0.03 2 o 3 (99.99%), Al 2 o 3 (99.99%), CeO 2 (99.99%), SiC (99.9%) raw materials, using a planetary ball mill for 10-20 h;

[0032] (2) Put the precursor mixture obtained in step (1) into a high-purity alumina crucible, and then place it in a high-temperature tubular furnace. Under a reducing atmosphere, keep it at 1500 °C for 5 h, and the heating rate is 600 °C / h , the synthesized phosphor is naturally cooled with the furnace body;

[0033] (3) Take out the phosphor powder synthesized in step (2), put it into a beaker filled with deionized water, add concentrated hydrochloric acid with a mass fraction of 36%-38%, and the volume ratio of deionized water to concentrated hydrochloric acid is 10: 1. Stir at 100 °C for 20 min, let stand to separate layers, ...

Embodiment 3

[0034] Example 3: Y 2.925 al 5 o 12 :0.075Ce,0.05SiC

[0035](1) Set the target product Y 2.925 al 5 o 12 : 0.075Ce, 0.05SiC has a mass of 20 g, and Y is weighed according to the ratio of Y:Al:Ce:Si: 2.925:5:0.075:0.05 2 o 3 (99.99%), Al 2 o 3 (99.99%), CeO 2 (99.99%), SiC (99.9%) raw materials, using a planetary ball mill for 10-20 h;

[0036] (2) Put the precursor mixture obtained in step (1) into a high-purity alumina crucible, and then place it in a high-temperature tubular furnace. Under a reducing atmosphere, keep it at 1500 °C for 5 h, and the heating rate is 600 °C / h , the synthesized phosphor is naturally cooled with the furnace body;

[0037] (3) Take out the phosphor powder synthesized in step (2), put it into a beaker filled with deionized water, add concentrated hydrochloric acid with a mass fraction of 36%-38%, and the volume ratio of deionized water to concentrated hydrochloric acid is 10: 1. Stir at 100 °C for 20 min, let stand to separate layers, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com