Grinding fluid special for hard alloy

A technology of cemented carbide and grinding fluid, which is applied in the field of special grinding fluid for cemented carbide, to achieve the effects of long slot change time, improved production environment, and low VOC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The special grinding fluid for cemented carbide of the present invention is composed of the following components in mass percentage: 15% cyclohexyldiethanolamine, 10% tricarboxylic acid, 5% undecanedioic acid mixture, 2% benzotriazole derivative %, polyether modified ester 10%, potassium hydroxide 2%, neodecanoic acid 4%, fungicide BIT20 1%, polyether modified silicon defoamer 0.1%, water balance. Stir each component to mix well.

[0014] Cyclohexyldiethanolamine is preferably Clariant GENAMIN CH 020; benzotriazole derivatives are preferably Ciba’s Irgamet 42, and the polyether modified ester is selected from Shenzhen Aiyin Chemical’s 1509, and its structure is as follows:

[0015] Wherein n=5-15, R is 18 carbon alkyl;

[0016] The polyether modified silicon defoamer is preferably MS-575 of the United States.

Embodiment 2

[0018] The special grinding fluid for cemented carbide of the present invention is composed of the following components in mass percentage: 9% cyclohexyldiethanolamine, 20% sebacic acid, 1% benzotriazole derivatives, 15% polyether modified ester, Potassium hydroxide 0.5%, isooctanoic acid 5%, fungicide BIT20 1%, polyether modified silicon defoamer 0.3%, water balance.

[0019] The sources of raw materials used and the preparation method are the same as in Example 1.

Embodiment 3

[0021] The special grinding fluid for cemented carbide of the present invention is composed of the following components in mass percentage: 20% cyclohexyldiethanolamine, 3% tricarboxylic acid, 7% undecanedioic acid, 10% sebacic acid, benzotri Azole derivatives 3%, polyether modified ester 8%, potassium hydroxide 5%, neodecanoic acid 1%, isooctanoic acid 1%, isononanoic acid 3%, fungicide BIT20 2%, polyether modified silicon disinfectant Foaming agent 0.4%, the balance of water.

[0022] The sources of raw materials used and the preparation method are the same as in Example 1.

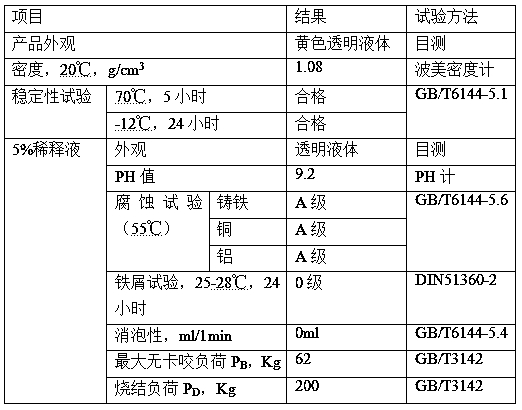

[0023] Typical technical data of Embodiment 1 of the present invention are shown in Table 1.

[0024] Table 1

[0025]

[0026] The cemented carbide grinding fluid prepared in Example 1 of the present invention was tested at a precision tool manufacturer (Japanese company) in Cangzhou at a concentration of 5-10%, and the original grinding fluid was successfully replaced. The original grinding flui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com