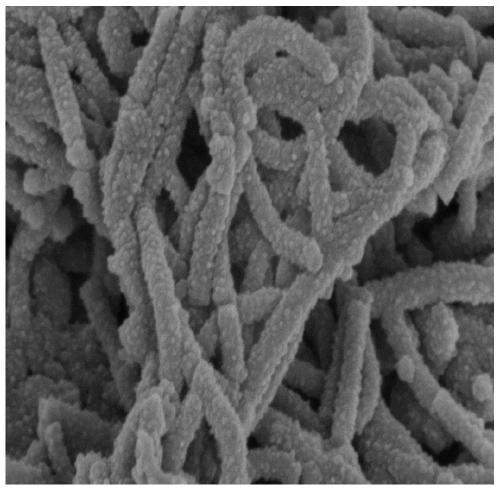

Rod-like polyaniline/wood electrode material as well as preparation method and application thereof

An electrode material, polyaniline technology, applied in the field of rod-shaped polyaniline/wood electrode materials and its preparation, can solve the problems of commercialization of poor cycle stability, achieve good cycle stability, improve electrical conductivity and structural stability, The effect of improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

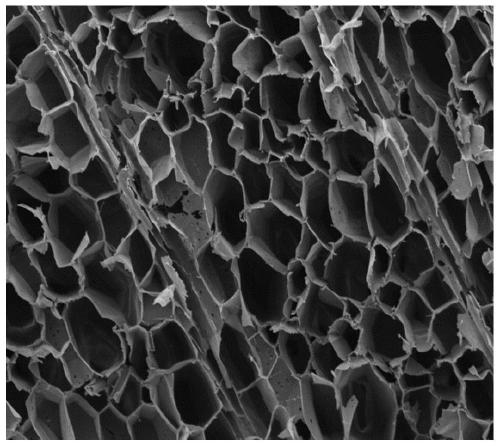

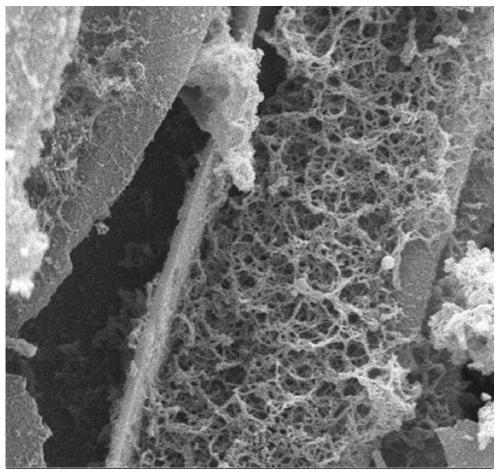

[0036] The invention discloses a method for preparing a rod-shaped polyaniline / wood electrode material, which aims to solve the problems of high preparation cost, low energy efficiency and poor electrical conductivity of biomass energy storage materials, comprising the following steps,

[0037] Step 1, delignifying the wood,

[0038] Cut the wood into thin slices with a length of 1-4cm, a width of 0.5-1cm, and a thickness of 1-5mm. Weigh 0.2-0.4g of sodium chlorite and 1-1.5ml of glacial acetic acid into a 100ml beaker and dissolve in 25-50ml of deionized water. Then put the prepared wood into the beaker, and obtain the delignified wood under the condition of 80-90°C with a rotation speed of 100-200rpm for 12-18 hours, put it into the refrigerator at -20-15°C for 4-12 hours, and then Freeze-drying at -50 to -40°C for 10 to 12 hours to obtain dried delignified wood;

[0039] Step 2: Take 10-15ml of deionized water in a beaker and add 0.5-5g of aniline, and perform magnetic sti...

Embodiment 1

[0048] A kind of preparation method of rod-shaped polyaniline / wood electrode material of the present invention comprises the following steps,

[0049] Step 1: Cut the wood into slices of 4cm in length, 1cm in width and 5mm in thickness, weigh 0.4g of sodium chlorite and 1.3ml of glacial acetic acid into a 100ml beaker and dissolve in 25ml of deionized water, then put the prepared wood into the beaker , after 12 hours under the condition of 80 ° C and 100 rpm to obtain delignified wood; put it into the refrigerator, freeze at -20 ° C for 12 h, and then freeze-dry it at -45 ° C for 5 h to obtain dried delignified wood;

[0050] Step 2, take 10ml of deionized water in a beaker and add 0.87g of aniline, carry out magnetic stirring, prepare 2mol / L hydrochloric acid solution, add dropwise to the aniline solution, until the pH reaches 2, continue magnetic stirring for 5min, weigh 2.13 g ammonium persulfate, add 10ml deionized water and stir until dissolved;

[0051] Step 3, put the ...

Embodiment 2

[0053] A kind of preparation method of rod-shaped polyaniline / wood electrode material of the present invention comprises the following steps,

[0054] Step 1: Cut the wood into slices of 4cm in length, 1cm in width and 2mm in thickness, weigh 0.4g of sodium chlorite and 1.3ml of glacial acetic acid into a 100ml beaker and dissolve in 25ml of deionized water, then put the prepared wood into the beaker , after 12 hours under the condition of 80 ° C and 100 rpm to obtain delignified wood; put it into the refrigerator, freeze at -20 ° C for 12 h, and then freeze-dry it at -50 ° C for 5 h to obtain dried delignified wood;

[0055] Step 2, take 10ml of deionized water in a beaker and add 2.61g of aniline, and perform magnetic stirring. Prepare a 2mol / L hydrochloric acid solution, add it dropwise to the aniline solution until the pH reaches 2, continue magnetic stirring for 5 minutes, weigh 6.39g of ammonium persulfate, add 10ml of deionized water and stir until dissolved;

[0056] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com