Cefixime granules and preparation method thereof

A technology of cefixime and granules, which is applied in the field of cefixime granules and its preparation, can solve the problems of unfavorable safe use and long-term storage, low yield of cefixime granules, and different particle sizes of powders, etc. Adhesive and gelatinization effect, particle shape intact, solubility control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

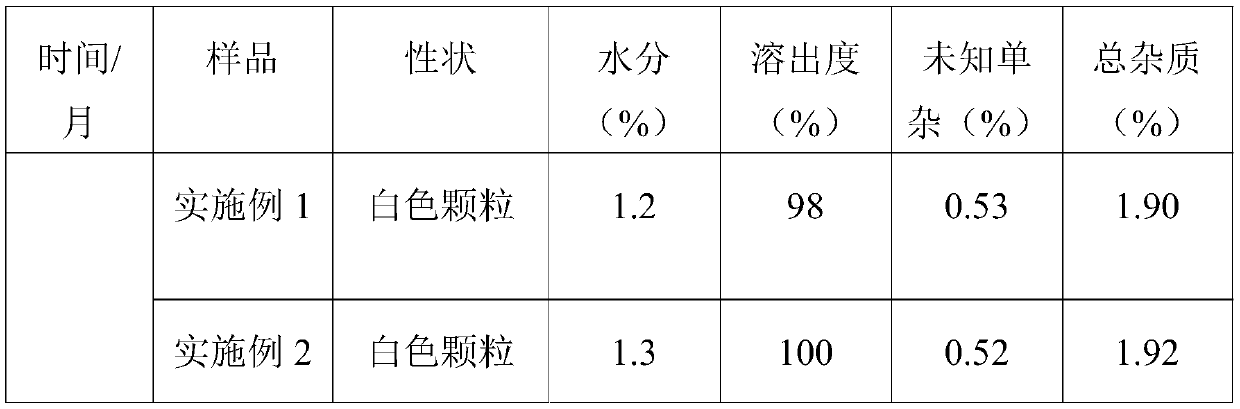

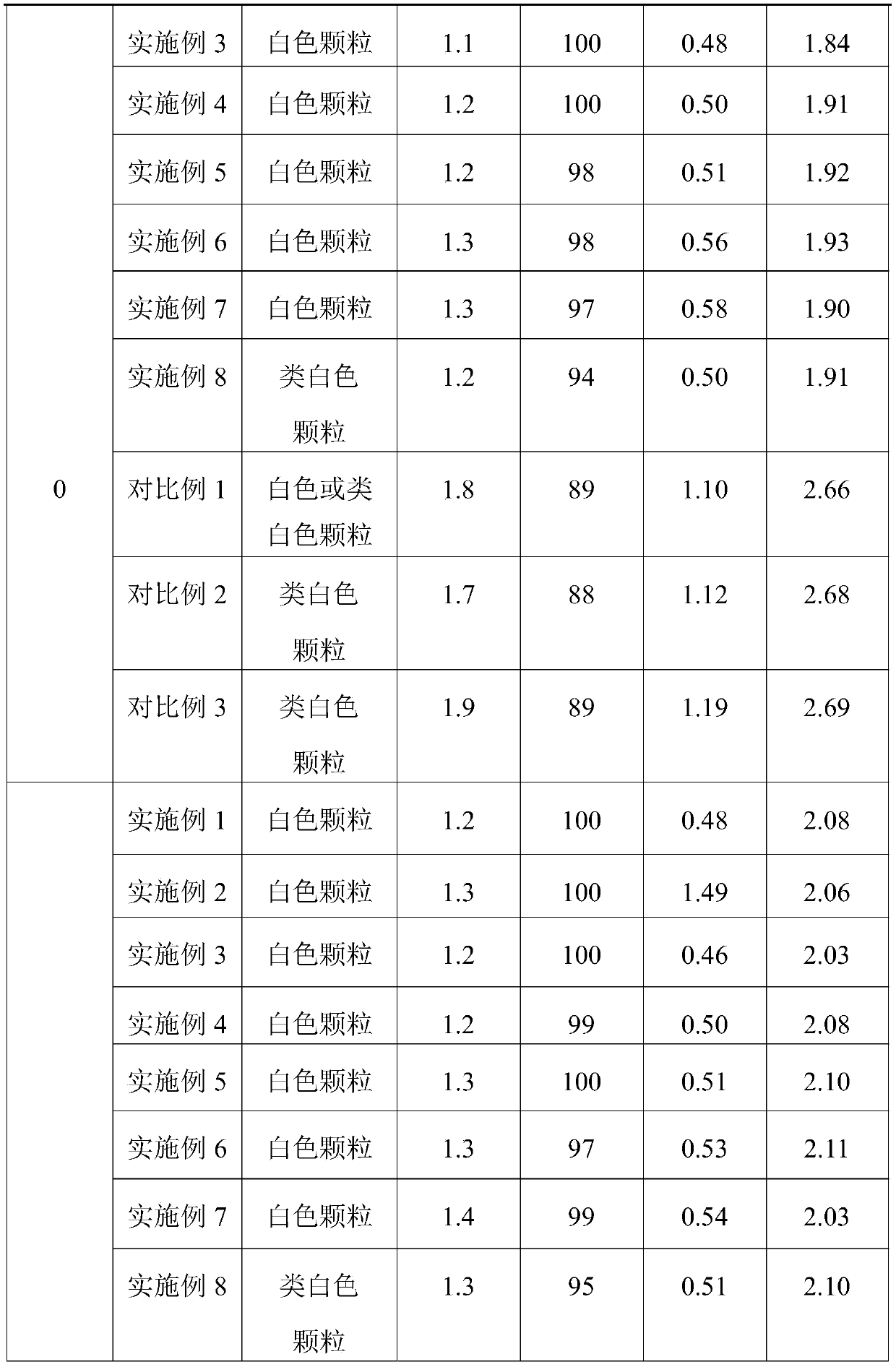

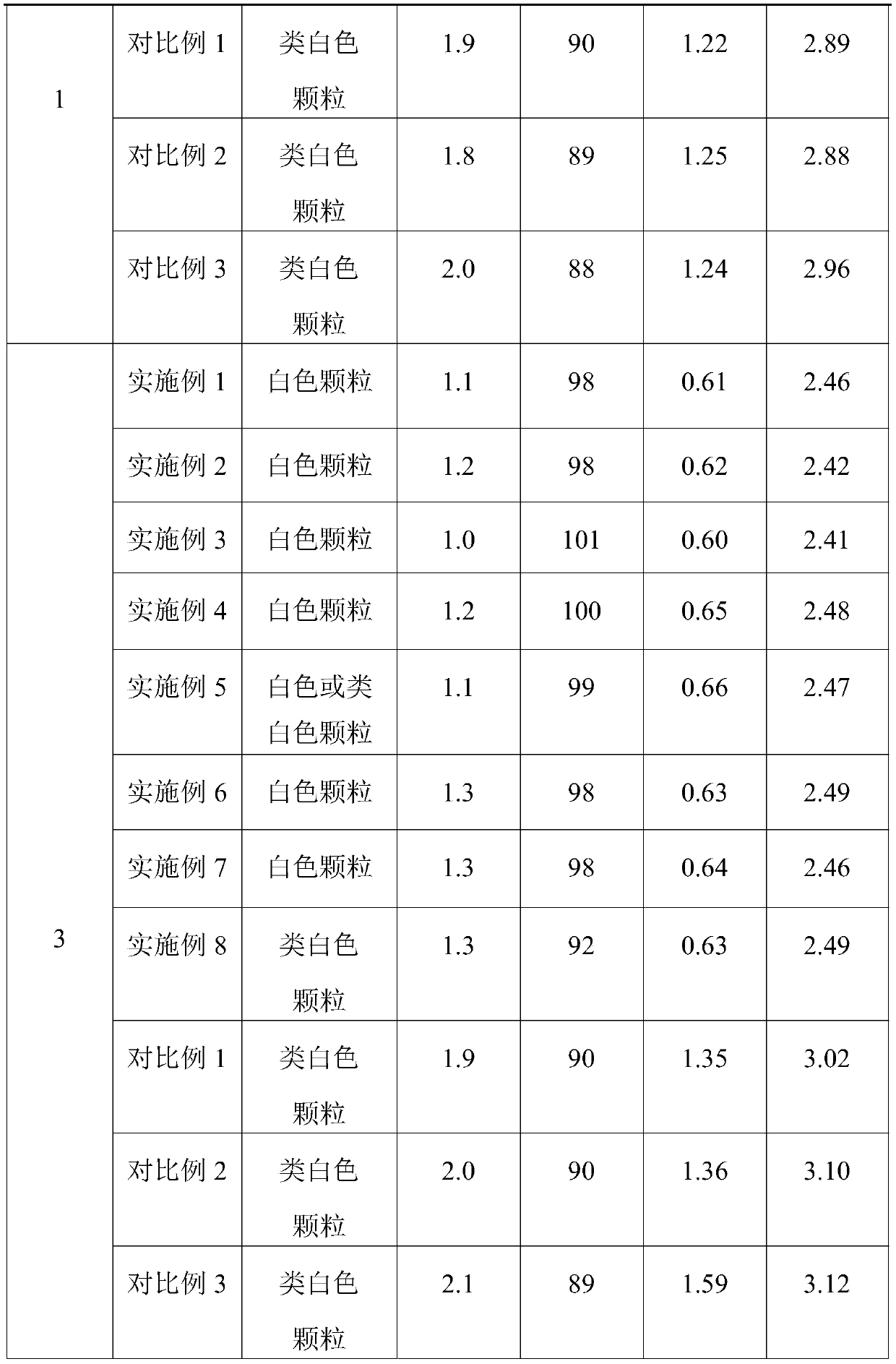

Examples

Embodiment 1

[0017] A cefixime granule: comprising the following raw materials in parts by weight: 30 parts of cefixime, 700 parts of sucrose, 10 parts of dextrin, 30 parts of sweet orange powder essence, 30 parts of gum arabic, 5 parts of tragacanth gum, and 0.2 parts of sunset yellow share.

Embodiment 2

[0019] A cefixime granule: comprising the following raw materials in parts by weight: 70 parts of cefixime, 900 parts of sucrose, 30 parts of dextrin, 70 parts of sweet orange powder essence, 70 parts of gum arabic, 15 parts of tragacanth gum, and 1.4 parts of sunset yellow share.

Embodiment 3

[0021] A cefixime granule, comprising the following raw materials in parts by weight: 50 parts of cefixime, 819 parts of sucrose, 20 parts of dextrin, 50 parts of sweet orange powder essence, 50 parts of gum arabic, 10 parts of tragacanth gum, and 1.0 parts of sunset yellow share;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com