Cartilage repair temperature-sensitive gel for injection and preparation method thereof

A technology of cartilage repair and temperature-sensitive gel, which is applied in the field of biomedicine, can solve the problems of precipitation temperature-sensitivity deterioration, achieve stable quality, good effect, and relieve pain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

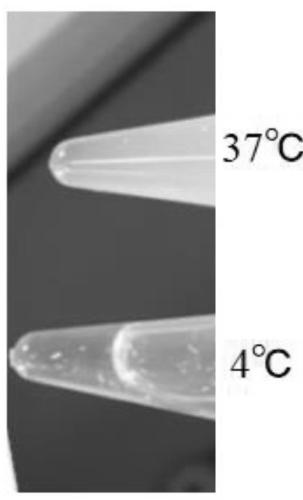

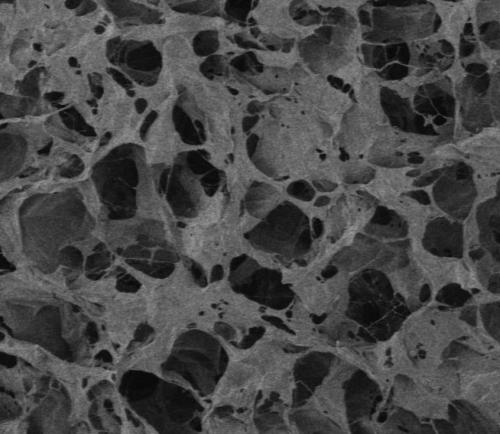

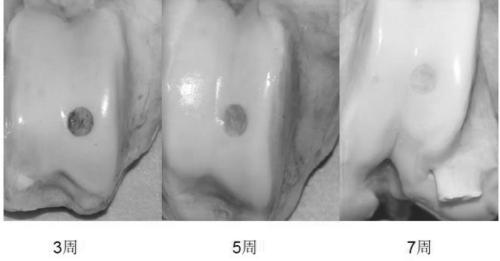

[0034] Prepare 200ml of 0.1mol / L phosphate buffer solution, slowly add 3g of chitosan (deacetylation degree 95%) under stirring conditions, stir at room temperature 25°C for 24h, then centrifuge the solution at high speed, remove the precipitate and obtain the initial concentration of 0.015g / ml chitosan solution.

[0035] Take 0.1 g of the initial collagen solution with an initial concentration of 0.001 g / ml, add it to the above 200 ml chitosan solution, stir for 24 hours, and let stand at 4° C. for 48 hours to prepare a mixture of chitosan and collagen.

[0036] To prepare 0.60g / ml sodium β-glycerophosphate solution, take 200μL chitosan and collagen mixture into a 1ml centrifuge tube, and add 50μL sodium β-glycerophosphate solution dropwise slowly at 4°C under agitation Add the above mixture solution to make the final concentration of β-sodium glycerophosphate solution 0.12g / ml.

[0037]Then, under the condition of stirring at 0°C, osteoblast factor was slowly added dropwise...

Embodiment 2

[0039] Prepare 200ml of 0.1mol / L phosphate buffer solution, slowly add 4g of chitosan (deacetylation degree 95%) under stirring conditions, stir at room temperature 25°C for 24h, then centrifuge the solution at high speed, remove the precipitate and obtain the initial concentration of 0.02g / ml chitosan solution.

[0040] Take 0.2 g of the initial collagen solution with an initial concentration of 0.001 g / ml, add it to the above-mentioned 200 ml chitosan solution, stir for 24 h, and let stand at 4° C. for 48 h to prepare a mixture of chitosan and collagen.

[0041] To prepare 0.60g / ml sodium β-glycerophosphate solution, take 200μL chitosan and collagen mixture and put it in a 1ml centrifuge tube, and slowly add 100μL sodium β-glycerophosphate solution dropwise at 4°C with stirring Add to the above mixture solution to make the final concentration of β-sodium glycerophosphate solution 0.2g / ml.

[0042] Then, under the condition of stirring at 0°C, osteoblast factor was slowly ad...

Embodiment 3

[0044] Prepare 200ml of 0.1mol / L phosphate buffer solution, slowly add 6g of chitosan (deacetylation degree 95%) under stirring conditions, stir at room temperature 25°C for 24h, then centrifuge the solution at high speed, and remove the precipitate to obtain an initial concentration of 0.03g / ml chitosan solution.

[0045] Take 0.3 g of the initial collagen solution with an initial concentration of 0.001 g / ml, add it to the above-mentioned 200 ml chitosan solution, stir for 24 hours, and let stand at 4° C. for 48 hours to prepare a mixture of chitosan and collagen.

[0046] To prepare 0.60g / ml sodium β-glycerophosphate solution, take 200μL chitosan and collagen mixture and put it in a 1ml centrifuge tube, and slowly add 200μL sodium β-glycerophosphate solution dropwise at 4°C under stirring condition Add the above mixture solution to make the final concentration of β-sodium glycerophosphate solution 0.3g / ml.

[0047] Then, under the condition of stirring at 4°C, osteoblast fa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com