Material with bionic hydrophobic-hydrophilic surface and preparation method and application of material

A hydrophilic surface, rusty technology, applied in the field of bionic materials, can solve the problems of short service life, complicated process, high cost, etc., and achieve the effect of excellent water collection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

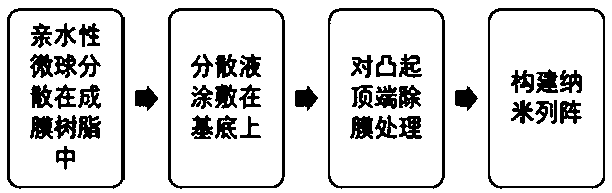

[0034] The following combination figure 1 The specific steps of the above preparation method are shown.

[0035] First, the hydrophilic microparticles are dispersed in the hydrophobic polymer (ie film-forming resin) to obtain a dispersion.

[0036] The kind of the above-mentioned film-forming resin is not limited. The film-forming resin can be water-based resin and / or solvent-based resin (water-based resin is a resin system with water as a dispersion medium, and the resin and water form a solution, and after the water volatilizes, a resin film material is formed. And the solvent-based resin is Resin system with organic solvent as dispersion medium). The water-based resin includes but not limited to one or more of water-based acrylic resin, water-based polyurethane, and derivatives thereof. The solvent-based resin includes, but is not limited to, one or more of solvent-based acrylic resin, solvent-based epoxy phenolic resin, solvent-based epoxy resin, solvent-based polyureth...

Embodiment 1

[0060] Hydrophilic SiO with a diameter of 85 μm 2 Ultrasonic dispersion of microspheres in aqueous acrylic resin to obtain hydrophilic SiO 2 A homogeneous dispersion with a mass fraction of microspheres of 10 wt%.

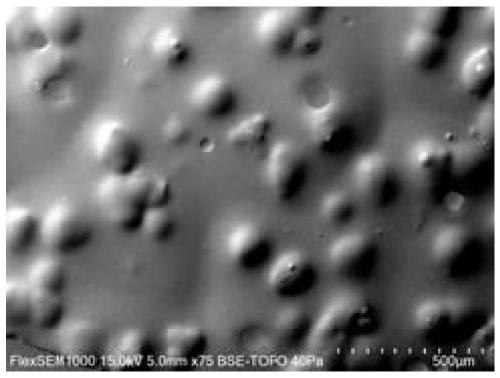

[0061] The dispersion is uniformly coated on the stainless steel substrate by dipping to obtain a micron-scale concave-convex structure and a fully hydrophobic surface (such as figure 2 shown).

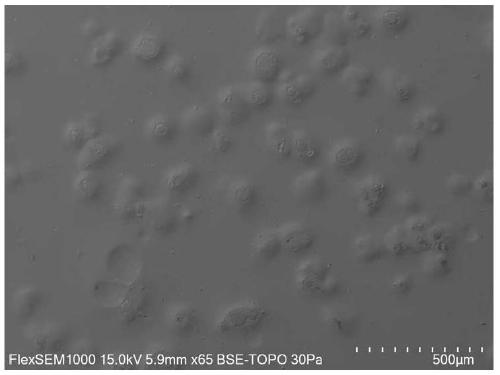

[0062] Sand the raised hydrophilic SiO lightly with dry sandpaper 2 Hydrophobic layer on the surface of microspheres, removing hydrophilic SiO 2 A water-based acrylic resin layer wrapped on the surface of the microspheres to obtain a partially hydrophilic surface (such as image 3 shown).

[0063] N on the coating surface 2 Plasma treatment was carried out with a treatment power of 300w, a pressure of 30-60pa, and a treatment time of 5 minutes to construct a nanoscale array and obtain a bionic hydrophobic-hydrophilic surface with a micro-nano composite structure (su...

Embodiment 2

[0066] Hydrophilic titanium oxide with a diameter of 40 μm was uniformly dispersed in the water-based polyurethane by magnetic stirring to obtain a dispersion liquid with a mass fraction of hydrophilic titanium oxide of 15 wt%.

[0067] The dispersion liquid is uniformly scraped and coated on the polyethylene substrate to obtain a micron-scale concave-convex structure and a fully hydrophobic surface.

[0068] Laser etching is used to etch the nanoscale structure on the surface of the coating to obtain a biomimetic hydrophobic-hydrophilic surface with a micro-nano composite structure.

[0069] Cut out a square film of 2cm x 2cm, and use a water collection device to conduct a water vapor collection test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Static contact angle | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com