Antistatic quick-drying water-based UV coating for wood-plastic product and preparation method thereof

A wood-plastic product, antistatic technology, applied in the field of coatings, can solve the problems of low adhesion, poor scratch resistance, weak wear resistance, etc., and achieve the effects of improved coating adhesion, extended service life, and strong curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

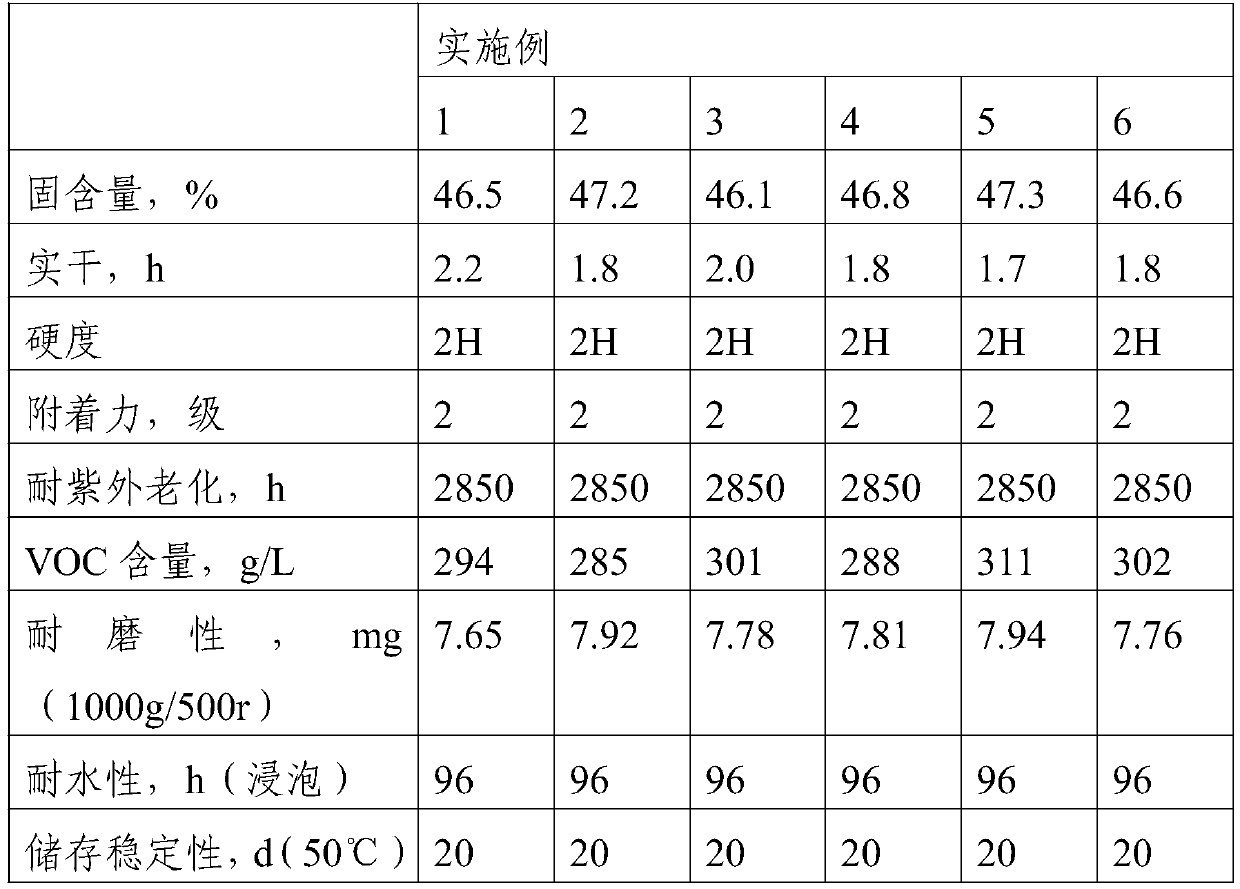

Examples

Embodiment 1

[0030] An antistatic quick-drying water-based UV coating for wood-plastic products, comprising the following parts by weight: 25 parts of water-based polyurethane acrylate resin, 15 parts of water-based epoxy acrylate resin, 2 parts of photocatalytically loaded sepiolite fiber, 1.5 parts of diatom mud, 0.5 parts of sodium humate, 2 parts of photoinitiator, 2 parts of additives, and 10 parts of water.

[0031] in:

[0032] The photocatalytic material loaded in the photocatalytically loaded sepiolite fiber is copper-doped titanium dioxide, the copper doping amount in the photocatalytic material is 1.26wt%, and the photocatalytic material loading rate in the sepiolite fiber is 35wt%;

[0033]The photoinitiator is a composition of 1-hydroxyl-cyclohexyl-phenyl ketone and 2-hydroxyl-2-methyl-1-phenyl-1-acetone with a mass ratio of 1.5:2;

[0034] The auxiliary agent includes the following components in mass percentage: 20% of defoamer, 15% of wetting agent, 15% of dispersant, 10% o...

Embodiment 2

[0042] An antistatic quick-drying water-based UV coating for wood-plastic products, comprising the following parts by weight: 30 parts of water-based polyurethane acrylate resin, 20 parts of water-based epoxy acrylate resin, 3 parts of photocatalytically loaded sepiolite fiber, 2 parts of diatom mud, 0.5 parts of sodium humate, 3 parts of photoinitiator, 3 parts of additives, and 10 parts of water.

[0043] in:

[0044] The photocatalytic material loaded in the photocatalytically loaded sepiolite fiber is copper-doped titanium dioxide, the copper doping amount in the photocatalytic material is 1.3wt%, and the photocatalytic material loading rate in the sepiolite fiber is 40wt%;

[0045] The photoinitiator is a composition of 1-hydroxyl-cyclohexyl-phenyl ketone and 2-hydroxyl-2-methyl-1-phenyl-1-acetone with a mass ratio of 1.5:2;

[0046] The auxiliary agent includes the following components in mass percentage: 15% of defoamer, 15% of wetting agent, 20% of dispersant, 10% of ...

Embodiment 3

[0054] An antistatic quick-drying water-based UV coating for wood-plastic products, comprising the following parts by weight: 20 parts of water-based polyurethane acrylate resin, 30 parts of water-based epoxy acrylate resin, 3 parts of photocatalytically loaded sepiolite fiber, 1.5 parts of diatom mud, 1 part of sodium humate, 2.5 parts of photoinitiator, 2.5 parts of additives, and 12 parts of water.

[0055] in:

[0056] The photocatalytic material loaded in the photocatalytically loaded sepiolite fiber is copper-doped titanium dioxide, the copper doping amount in the photocatalytic material is 1.5wt%, and the photocatalytic material loading rate in the sepiolite fiber is 40wt%;

[0057] The photoinitiator is a composition of 1-hydroxyl-cyclohexyl-phenyl ketone and 2-hydroxyl-2-methyl-1-phenyl-1-acetone with a mass ratio of 1:2;

[0058] The auxiliary agent includes the following components in mass percentage: 20% of defoaming agent, 10% of wetting agent, 20% of dispersing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com