Pulsed magnet field multi-orientation batch remanufacturing high-performance tool production line and method thereof

A pulsed magnetic field and remanufacturing technology, applied in the production line of metal cutting tool remanufacturing, can solve problems such as overheating, large contact resistance, and deformation of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

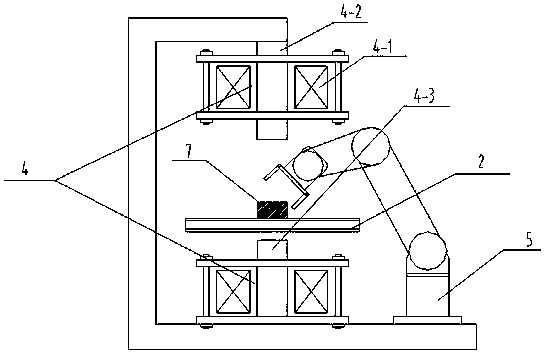

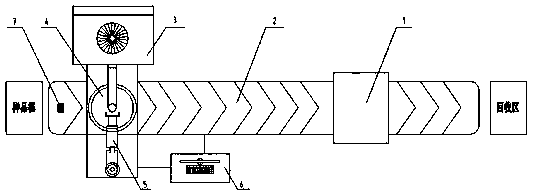

Image

Examples

example 1

[0017] 1. Take 30 W18 high-speed steel knives, place them in the gap between the iron cores through the robot arm, the gap distance is adjustable, the angle between the knives and the parallel conveyor belt is adjustable from 0-90°, apply a pulsed magnetic field, the magnetic field strength is 0.2T-3T, pulse The frequency is 5-200HZ, the pulse time is 5s-5min, and the hardness of the high-speed steel tool is increased by 2%-15% after the magnetic field remanufacturing treatment; a cutting comparison experiment is carried out to cut carbon steel. The life of the manufactured tool is 10-30% higher than that of the tool without magnetic field treatment;

[0018] 2. Take the YG8 cemented carbide milling cutter, transport it to the bottom of the moving iron core through the conveyor belt, and ensure that the cutting edge area of the front end of the milling cutter is in the middle of the moving iron core, apply a pulsed magnetic field, the magnetic field strength is 0.2T-3T, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com