Vanadate hydrate electrode material, preparation method thereof and application of vanadate hydrate electrode material

A technology of electrode materials and hydrates, which is applied in the field of nanomaterials and electrochemistry, can solve the problems of low ion diffusion coefficient, unusable high ion conductivity of electrolyte, and poor performance, so as to achieve simple preparation and improve ion diffusion ability , the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Weigh 5.0mmol V 2 o 5 Add to 65ml of deionized water, heat at 60°C and stir. Then weigh an appropriate amount of Ni (CH 3 COO) 2 4H 2 O and (CH 3 COO) 2 Mg·4H 2 O, CH 3 Add COOK to it, continue heating and stirring for 60 min to obtain a homogeneous solution. Then 2ml of ethanol and 3ml of acetone were added.

[0040] (2) Transfer the solution of step (1) to an 85ml hydrothermal reaction kettle, and carry out hydrothermal reaction at 200°C for 24 hours. After the reaction, the reaction kettle is naturally cooled at room temperature, and the resulting product is filtered and washed with deionized water. and ethanol were washed three times, and dried to obtain Ni 0.25 V 2 o 5 ·H 2 O, Mg 0.25 V 2 o 5 ·H 2 O and K 0.5 V 2 o 5 ·H 2 O samples.

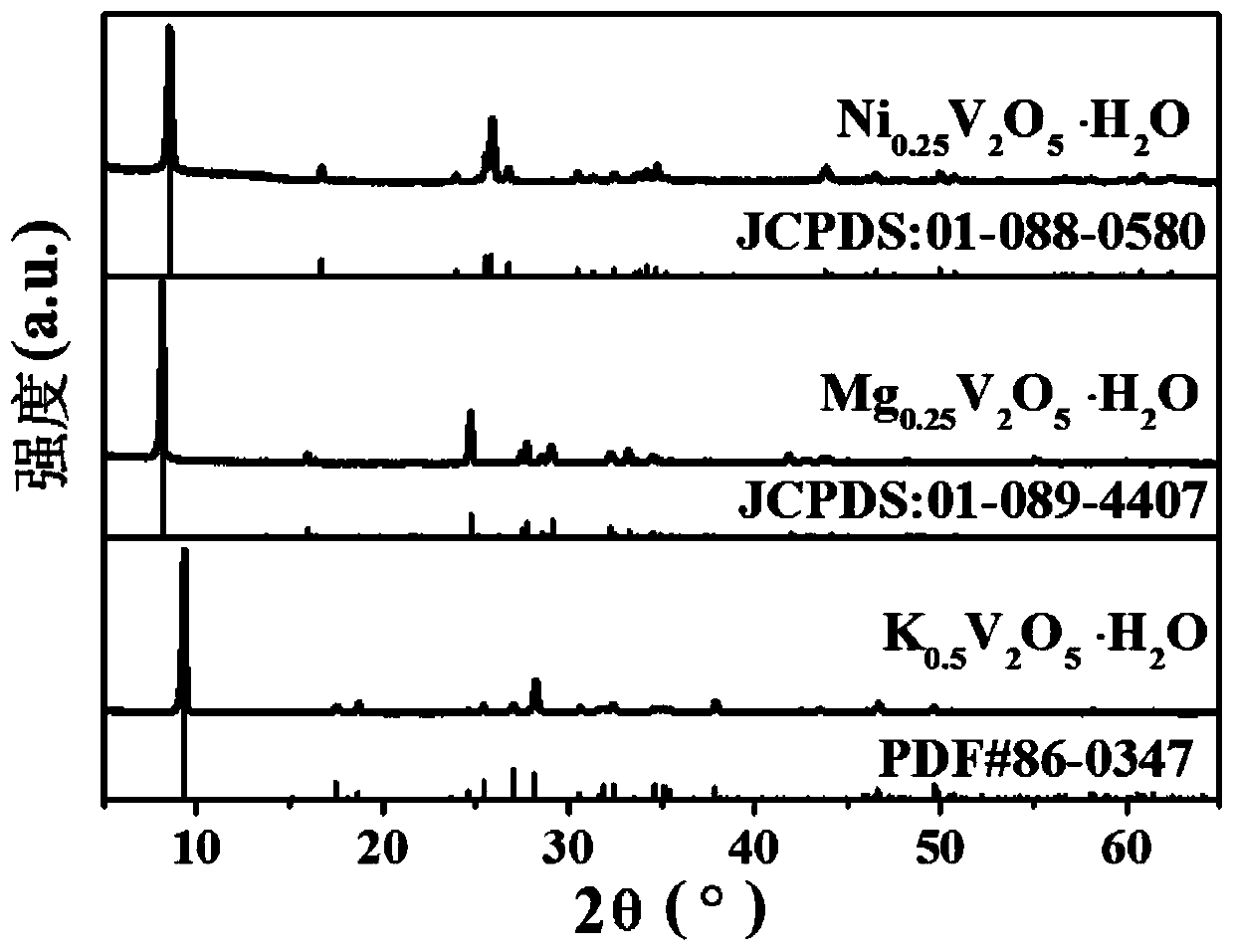

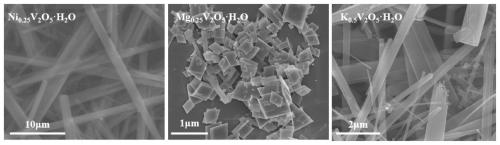

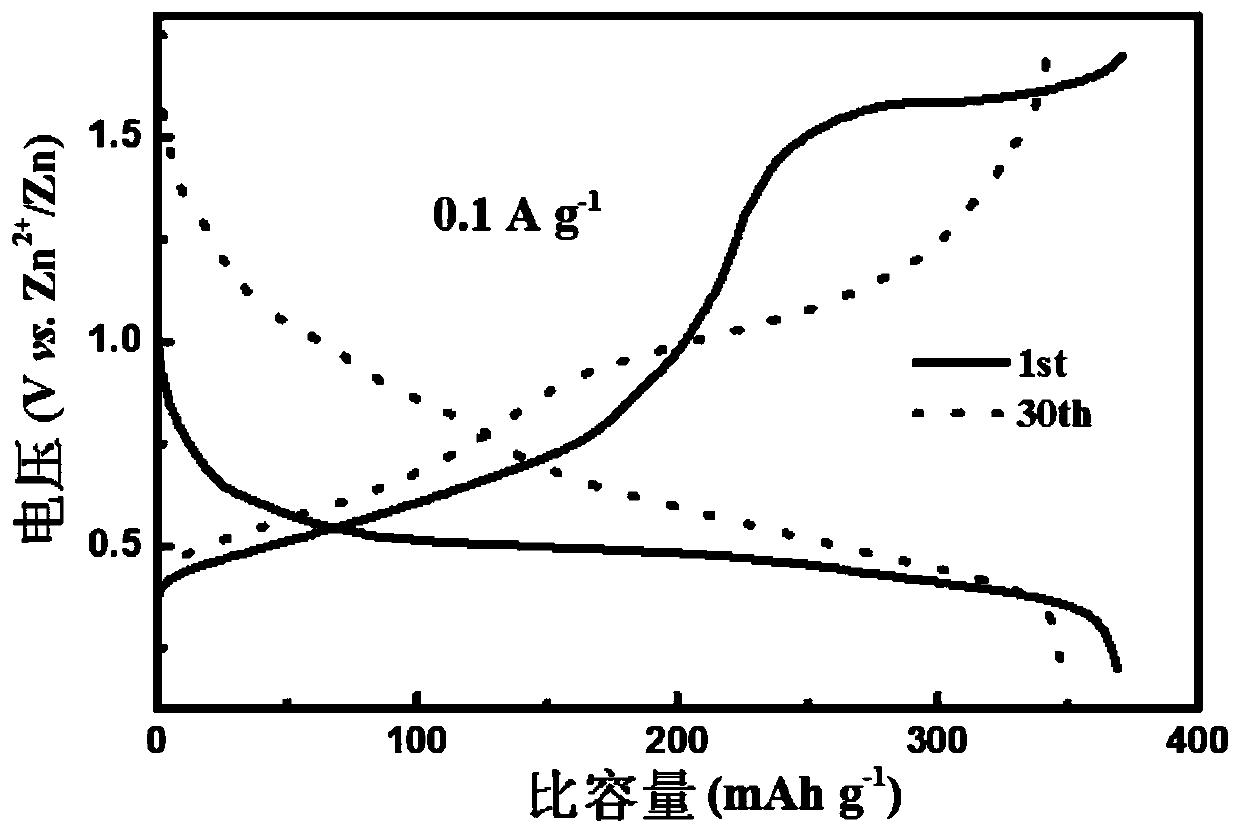

[0041] The phases of the nickel vanadate, magnesium vanadate and potassium vanadate obtained in this example were determined by X-ray diffraction pattern (XRD), and their microscopic morphology was determined...

Embodiment 2

[0044] (1) Weigh 5.0mmol V 2 o 5 Add to 65ml of deionized water, heat at 60°C and stir. Then weigh an appropriate amount of Ni (CH 3 COO) 2 4H 2 O, (CH 3 COO) 2 Mg·4H 2 O and CH 3 Add COOK to it, continue heating and stirring for 60 min to obtain a homogeneous solution. Then 2 ml of ethanol was added to the solution.

[0045] (2) Transfer the solution of step (1) to an 85ml hydrothermal reaction kettle, and carry out hydrothermal reaction at 200°C for 24 hours. After the reaction, the reaction kettle is naturally cooled at room temperature, and the resulting product is filtered and washed with deionized water. and ethanol were washed three times, and dried to obtain the product.

[0046] Compared with Example 1, due to not adding acetone, the pressure in the reactor is small, and the obtained Ni 0.25 V 2 o 5 ·H 2 O, Mg 0.25 V 2 o 5 ·H 2 O and K 0.5 V 2 o 5 ·H 2 O has poor crystallinity or a small amount of impurities. The XRD pattern compares the Ni prep...

Embodiment 3

[0048] (1) Weigh 5.0mmol V 2 o 5 Add to 65ml of deionized water, heat at 60°C and stir. Then weigh an appropriate amount of Ni (CH 3 COO) 2 4H 2 O, (CH 3 COO) 2 Mg·4H 2 O and CH 3 Add COOK to it, continue heating and stirring for 60 min to obtain a homogeneous solution. Then 2 ml of ethanol and 5 ml of acetone were added to the solution.

[0049] (2) Transfer the solution of step (1) to an 85ml hydrothermal reaction kettle, and carry out hydrothermal reaction at 200°C for 24 hours. After the reaction, the reaction kettle is naturally cooled at room temperature, and the resulting product is filtered and washed with deionized water. and ethanol were washed three times, and dried to obtain the product.

[0050] Compared with Example 1, due to adding more acetone, the pressure in the reactor is larger, and high crystallinity Ni is also obtained. 0.25 V 2 o 5 ·H 2 O, Mg 0.25 V 2 o 5 ·H 2 O and K 0.5 V 2 o 5 ·H 2 O samples, the electrochemical performance is no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com