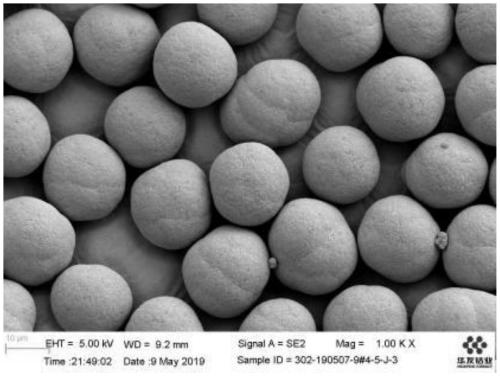

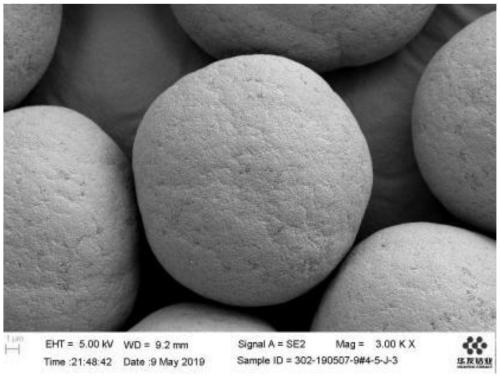

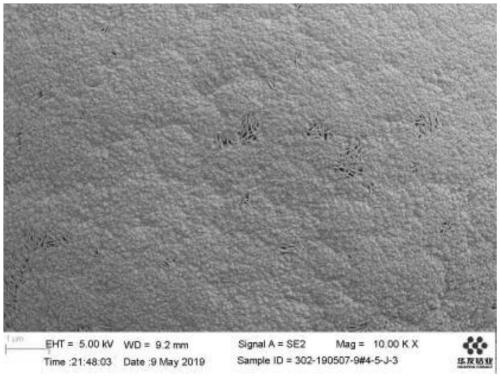

Nano basic aluminum cobalt carbonate/cobalt carbonate composite spherical precursor

A technology of aluminum carbonate and cobalt carbonate, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of uneven distribution of aluminum elements, inability to uniformly co-precipitate, and insignificant improvement effect. Achieve the effect of good aluminum distribution uniformity and excellent high-voltage cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Dissolve cobalt sulfate and aluminum sulfate octadecahydrate into mixed solution A, wherein the cobalt ion concentration is 120g / L, and the aluminum ion concentration is 3.38g / L; ammonium bicarbonate is dissolved into solution B with a concentration of 220g / L.

[0025] Use solution B as a base, heat up to 45°C, start stirring at 150rpm, add solution A at a flow rate of 380L / h until the pH value in the kettle drops to 7.6, then adjust the flow rate of solution A to 600L / h, and add solution B at the same time , by adjusting the flow rate of solution B, the pH value is controlled at 7.5-7.6. When the particle size of the dispersed sample reaches 4 μm, the feeding is completed, the stirring is stopped, and the solid-liquid separation is carried out in a static manner. Finally, the supernatant is pumped away to make room for continuous feeding. , repeat the above operations until the seed crystal size reaches 9 μm.

[0026] The slurry in the reactor is separated for the firs...

Embodiment 2

[0031] Dissolve cobalt chloride and aluminum sulfate octadecahydrate into mixed solution A, wherein the cobalt ion concentration is 150g / L, and the aluminum ion concentration is 3g / L; ammonium bicarbonate is dissolved into solution B with a concentration of 220g / L.

[0032] Use solution B as a base, heat up to 45°C, start stirring at 150rpm, add solution A at a flow rate of 380L / h until the pH value in the kettle drops to 7.6, then adjust the flow rate of solution A to 600L / h, and add solution B at the same time , by adjusting the flow rate of solution B, the pH value is controlled at 7.5-7.6. When the particle size of the dispersed sample reaches 4 μm, the feeding is completed, the stirring is stopped, and the solid-liquid separation is carried out in a static manner. Finally, the supernatant is pumped away to make room for continuous feeding. , repeat the above operations until the seed crystal size reaches 9 μm.

[0033] The slurry in the reactor is separated for the first ...

Embodiment 3

[0037] Cobalt sulfate and aluminum chloride are dissolved into mixed solution A, wherein cobalt ion concentration 90g / L, aluminum ion concentration 0.8g / L; Ammonium bicarbonate is dissolved into concentration and is the solution B of 220g / L.

[0038] Use solution B as a base, heat up to 45°C, start stirring at 150rpm, add solution A at a flow rate of 380L / h until the pH value in the kettle drops to 7.6, then adjust the flow rate of solution A to 600L / h, and add solution B at the same time , by adjusting the flow rate of solution B, the pH value is controlled at 7.5-7.6. When the particle size of the dispersed sample reaches 4 μm, the feeding is completed, the stirring is stopped, and the solid-liquid separation is carried out in a static manner. Finally, the supernatant is pumped away to make room for continuous feeding. , repeat the above operations until the seed crystal size reaches 9 μm.

[0039] The slurry in the reactor is separated for the first time, that is, half of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com