Multi-layer anodic aluminum oxide selective reflection material, preparation method and application of multi-layer anodic aluminum oxide selective reflection material in cooling of disc type solar cell

An anodized aluminum, solar panel technology, applied in photovoltaic power generation, electrical components, photovoltaic modules, etc., can solve the problems of reduced service life, low conversion efficiency, decline, etc., to achieve the effect of improving efficiency and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A multi-layer anodic aluminum oxide selective reflection material. The selective reflection light-gathering layer reflects the sunlight of 0.3-1.1 microns and transmits the sunlight of 1.1-2.5 microns. The manufacturing method of the selective reflection light-concentrating layer:

[0037] Using the principle of electrochemical oxidation, pure aluminum is used as anode, graphite carbon rod is used as cathode, placed in a container containing oxalic acid (or phosphoric acid, selenic acid, sulfuric acid) as electrolyte, and 30-50V constant voltage or current density is applied to both ends of the electrode. 0-10mA / cm 2 Constant current, and use a magnetic stirrer to continuously stir the electrolyte. The entire device is placed in a low temperature environment of 0-5°C. After reacting for 1-3 hours, pure aluminum is taken out as a sample. A mixture of chromium trioxide and phosphoric acid is used to remove the surface of the sample. Oxide film; samples with oxide film remove...

Embodiment 2

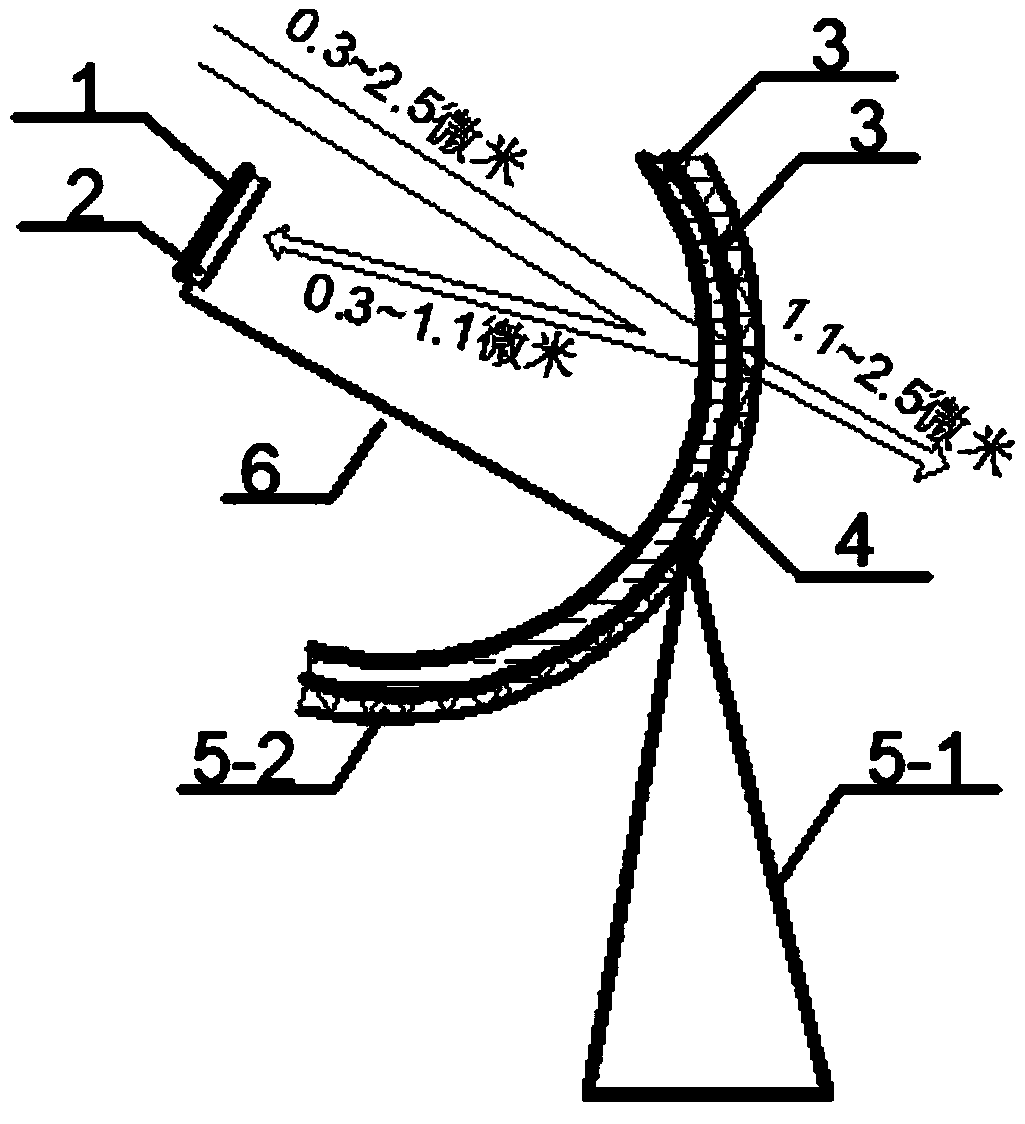

[0039] Such as figure 1 As shown, the dish-type solar panel includes a supporting tower 5-1, a reflecting frame 5-2, a battery support 6, a solar cell 2, a radiation cooling layer 1, and a combined material layer;

[0040] The reflection frame is arranged on the support tower, and the solar cell is installed on the reflection frame through a battery bracket, so that the solar cell is located at the reflection focus of the reflection frame;

[0041] The radiation cooling layer is placed on the back plate of the solar cell, the combined material layer is placed on the reflection frame 5-2 of the dish-type solar cell panel, and the combined material layer includes a selective reflection light-concentrating layer 4 and a protective layer 3 The selective reflective light-concentrating layer 4 is arranged between the two protective layers 3, and the protective layer 3 is made of PMMA plate to prevent the selective reflective light-concentrating layer 4 from being exposed to the environme...

Embodiment 3

[0045] The passive cooling method of the dish-type solar cell based on selective reflection of the present invention includes the following steps:

[0046] The first step: using electrochemical principles to use pure aluminum as the anode, graphite carbon rod as the cathode, placed in a container containing oxalic acid (or phosphoric acid, selenic acid, sulfuric acid) as the electrolyte, and apply constant voltage or constant current to both ends of the electrode , And use a magnetic stirrer to continuously stir the electrolyte, place the whole device in a low temperature environment, take out the sample after a period of reaction, and use a mixture of chromium trioxide and phosphoric acid to remove the oxide film on the sample surface;

[0047] Step 2: The sample with the oxide film removed undergoes a second reaction under periodic voltage or periodic current. As the pure aluminum is continuously oxidized in the electrolyte and the oxide film is continuously dissolved, a multilaye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com