Phosphorous and nitrogen-containing flame retardant and its flame-retardant polyacrylonitrile fiber and preparation method

A flame retardant polyacrylonitrile, flame retardant technology, applied in the direction of chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., can solve the problem of unfriendly, difficult industrialization and synthesis of flame retardant Complex process and other issues, to achieve the effect of easy industrialization, improved flame retardant performance, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

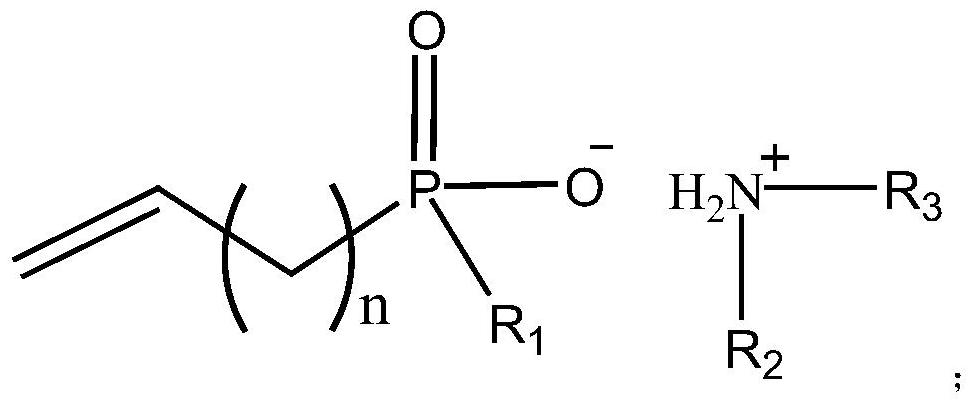

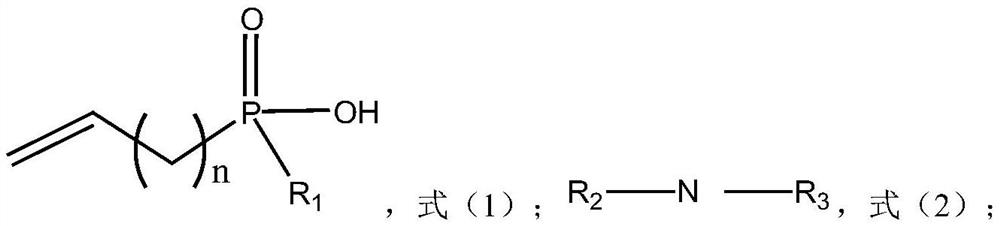

[0040] Preparation of phosphorus and nitrogen flame retardant monomers:

[0041]Feed vinylphosphonic acid and urea at a molar ratio of 1:1, react in an aqueous solution at 90°C for 3 hours, wash and purify by rotary evaporation and distilled water to obtain a white powder of vinylphosphonic acid amine salt, and dry it at 80°C for later use . Yield 80.4 wt%.

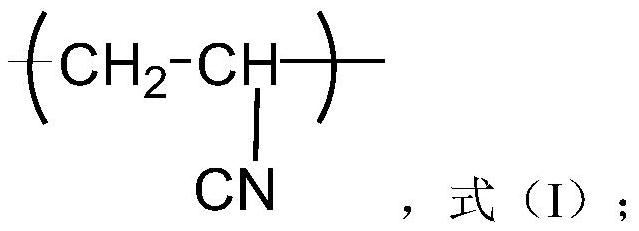

[0042] Preparation of phosphorus and nitrogen flame retardant polyacrylonitrile copolymer:

[0043] The method of solution polymerization is adopted, and dibenzoyl peroxide is used as the initiator, and the amount of the initiator accounts for 0.5% of the weight of the monomer, and the ratio of the monomer acrylonitrile, methyl acrylate, and vinyl phosphate amine salt is 76:9:15 , accounting for 15% of the weight of the entire system; the solvent dimethyl sulfoxide accounted for 85% of the weight of the entire system, the polymerization temperature was 70°C, the reaction time was 24 hours, and the yield was 58.7wt%. Af...

Embodiment 2

[0045] Preparation of phosphorus and nitrogen flame retardant monomers:

[0046] Feed vinylphosphonic acid and melamine at a molar ratio of 1:1, react in an aqueous solution at 90°C for 6 hours, wash and purify by rotary steaming and distilled water to obtain white powder of vinylphosphonic acid melamine salt, dry at 80°C for later use . Yield 82.3 wt%.

[0047] Preparation of phosphorus and nitrogen flame retardant polyacrylonitrile copolymer:

[0048] The method of solution polymerization is adopted, with dibenzoyl peroxide as the initiator, the amount of the initiator accounts for 0.5% of the weight of the monomer, and the ratio of the monomer acrylonitrile, methyl acrylate, and vinyl phosphate melamine salt is 76:9:15 , accounting for 15% of the weight of the entire system; the solvent dimethyl sulfoxide accounted for 85% of the weight of the entire system, the polymerization temperature was 70°C, the reaction time was 24 hours, and the yield was 64.7wt%. After film coa...

Embodiment 3

[0050] Preparation of phosphorus and nitrogen flame retardant monomers:

[0051] Feed vinylphosphonic acid and melamine at a molar ratio of 1:1, react in an aqueous solution at 90°C for 6 hours, wash and purify by rotary steaming and distilled water to obtain white powder of vinylphosphonic acid melamine salt, dry at 80°C for later use . Yield 82.3 wt%.

[0052] Preparation of phosphorus and nitrogen flame retardant polyacrylonitrile copolymer:

[0053] The method of solution polymerization is adopted, with dibenzoyl peroxide as the initiator, the amount of the initiator accounts for 1% of the weight of the monomer, and the ratio of the monomer acrylonitrile, methyl acrylate, and vinyl phosphate melamine salt is 76:9:15 , accounting for 15% of the weight of the entire system; the solvent dimethyl sulfoxide accounted for 85% of the weight of the entire system, the polymerization temperature was 70 ° C, the reaction time was 17 hours, and the yield was 54.1 wt%. After film co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com