Bistable electrofluorochromatic polymer material, preparation method and applications thereof

A polymer material, bistable technology, applied in the field of bistable electroluminescent color-changing polymer materials and its preparation, can solve the problems of difficult design and synthesis, complicated preparation process, difficult product purification, etc., and achieve good reversibility , high luminous brightness, simple and efficient preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

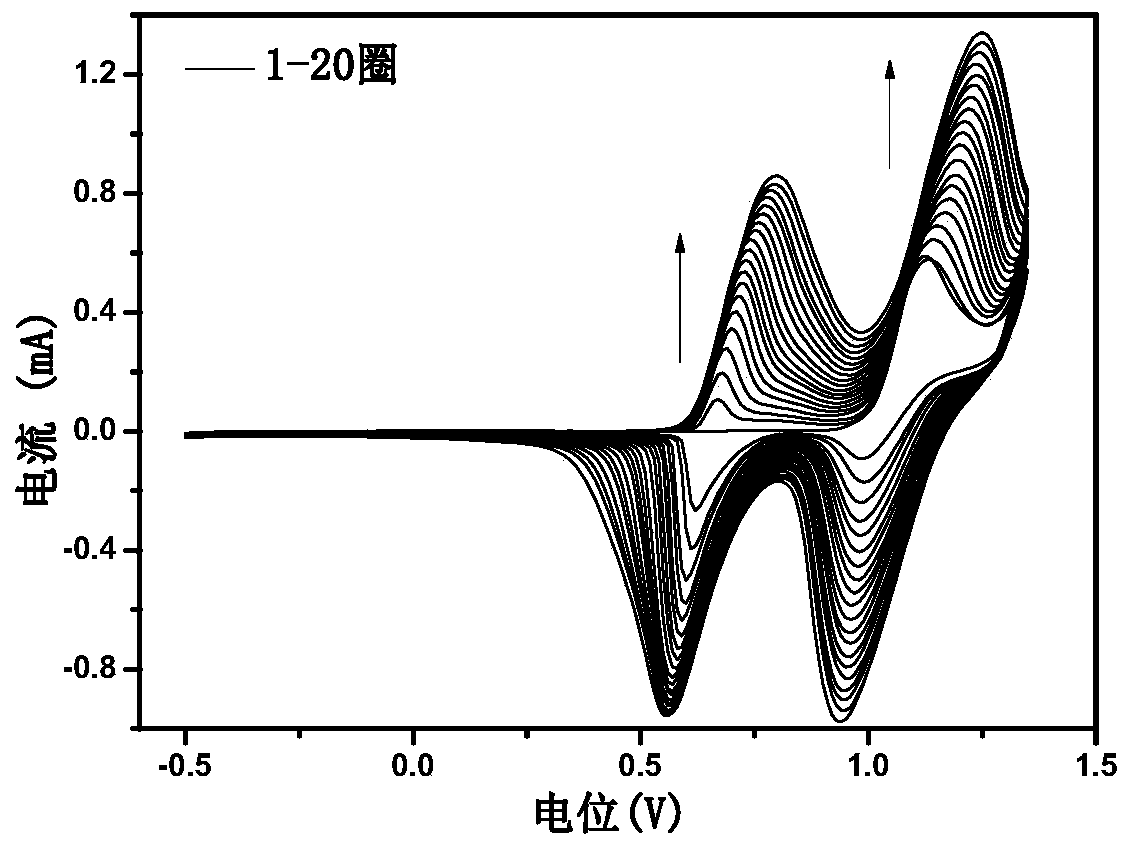

Image

Examples

preparation example Construction

[0044] The preparation method of this polymer material comprises the following steps:

[0045] Step 1. Synthesis of carbazole derivative precursor: Dissolve p-hydroxybenzonitrile in dry N,N-dimethylformamide, then add potassium carbonate and potassium iodide in turn, stir for a period of time, slowly dropwise dissolve in dry The 9-(6-bromohexyl) carbazole solution of N,N-dimethylformamide was heated and stirred at 80-120°C, and the reaction progress was monitored by silica gel chromatography (TLC). After the reaction was completed, it was cooled and used The reaction was quenched with distilled water, and extracted with dichloromethane to obtain an organic phase. After the organic phase was concentrated, it was recrystallized with ethanol to obtain a white solid product, namely the precursor of the carbazole derivative.

[0046] Its synthetic route is as follows:

[0047]

[0048]Step 2, the synthesis of polymer monomer II: the carbazole derivative precursor is dissolved i...

Embodiment 1

[0055] Step 1, the synthesis of carbazole derivative precursor

[0056] Take a flask and dissolve 1.33g of p-hydroxybenzonitrile in 20mL of dry N,N-dimethylformamide, then add 2.50g of K 2 CO 3 and 0.25g KI, stirred in an oil bath at 80°C for 30min; 3.60g of 9-(6-bromohexyl)carbazole was dissolved in 5mL of dry N,N-dimethylformamide, and the solution was placed in The constant pressure titration funnel was slowly added dropwise to the above flask, stirred at 80°C for 12 hours, cooled and quenched with distilled water, extracted with dichloromethane to obtain the organic phase, washed three times with saturated brine, dried over anhydrous magnesium sulfate, and concentrated the organic phase. After recrystallization from ethanol, a white solid product, namely the precursor of the carbazole derivative, was obtained. The mass of the carbazole derivative precursor obtained at this time was 2.51 g, and the yield was 65%.

[0057] 1 H NMR (500MHz, CDCl 3 ,25℃): δ(ppm)8.146(d,J=...

Embodiment 2

[0064] Step 1, the synthesis of carbazole derivative precursor

[0065] Take a flask and dissolve 1.33g of p-hydroxybenzonitrile in 20mL of dry N,N-dimethylformamide, then add 2.50g of K 2 CO 3 and 0.25g KI, stirred in an oil bath at 90°C for 30min; 3.60g of 9-(6-bromohexyl)carbazole was dissolved in 5mL of dry N,N-dimethylformamide, and the solution was placed in The constant pressure titration funnel was slowly added dropwise to the above flask, stirred at 90°C for 10 h, cooled and quenched with distilled water, extracted with dichloromethane to obtain the organic phase, washed three times with saturated brine, dried over anhydrous magnesium sulfate, and concentrated the organic phase. After recrystallization from ethanol, a white solid product, namely the precursor of the carbazole derivative, was obtained. The mass of the carbazole derivative precursor obtained at this time was 2.71 g, and the yield was 70.8%.

[0066] Step 2, the synthesis of polymer monomer II

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com