Preparation method of wood-based-graphene conductive composite material

A conductive composite material and composite material technology, applied in the field of preparation of wood-based-graphene conductive composite materials, can solve the problems of easy deformation, weakening wood moisture absorption, etc., and achieve the effects of weakening moisture absorption, improving mechanical properties, and expanding application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

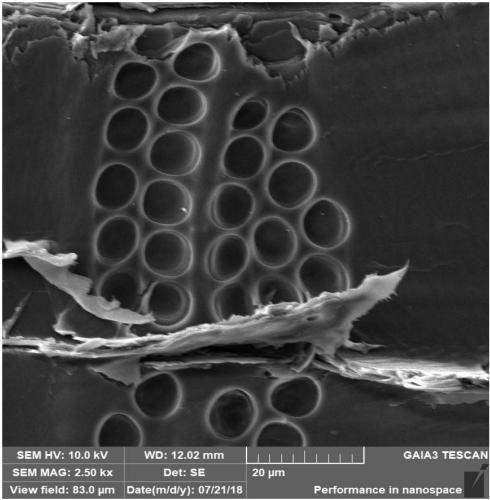

[0050] The present embodiment provides a wood-based-graphene conductive composite material, which is prepared through the following steps:

[0051] (1) Wood pretreatment and extraction process: Use 95°C deionized water to boil the wood (poplar material) for 2 hours, then freeze it for 2 days, then steam the composite material for 2 hours, and then freeze it for 2 days. Then boil it with deionized water, repeat the above process several times until the color of the liquid after deionized water is clear and transparent, and finally dry it (dry at 103°C for 30 minutes, dry at 80°C for 4 hours, dry at 60°C under a vacuum of 0.2MPa Dry 2h).

[0052] (2) impregnate the graphene oxide dispersion liquid with a concentration of 3mg / mL into the fast-growing material body pretreated in step (1) under vacuum conditions, adopt a pulsed vacuum method, the vacuum degree is 0.8MPa, and vacuum impregnate for 10 minutes , normal pressure impregnation for 3 minutes, and then vacuum impregnation...

Embodiment 2

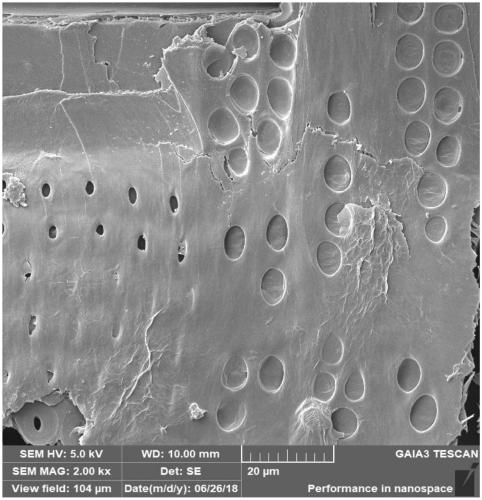

[0059] The present embodiment provides a wood-based-graphene conductive composite material, which is prepared through the following steps:

[0060] (1) Wood pretreatment and extraction process: use 95°C deionized water to boil the wood (poplar material) for 2 hours, then perform a one-week saturated water treatment and freeze for 2 days, and then steam the composite material Treated for 2 hours, then frozen for 2 days, then boiled with deionized water, repeated the above process until the color of the liquid after deionized water was boiled was clear and transparent, and finally dried (dried at 103°C for 30 minutes, dried at 80°C for 4h, in Dry at 60°C for 2h under a vacuum of 0.2MPa).

[0061] (2) impregnate the graphene oxide dispersion liquid with a concentration of 3mg / mL into the fast-growing material body pretreated in step (1) under vacuum conditions, adopt a pulsed vacuum method, the vacuum degree is 0.8MPa, and vacuum impregnate for 10 minutes , normal pressure impre...

Embodiment 3

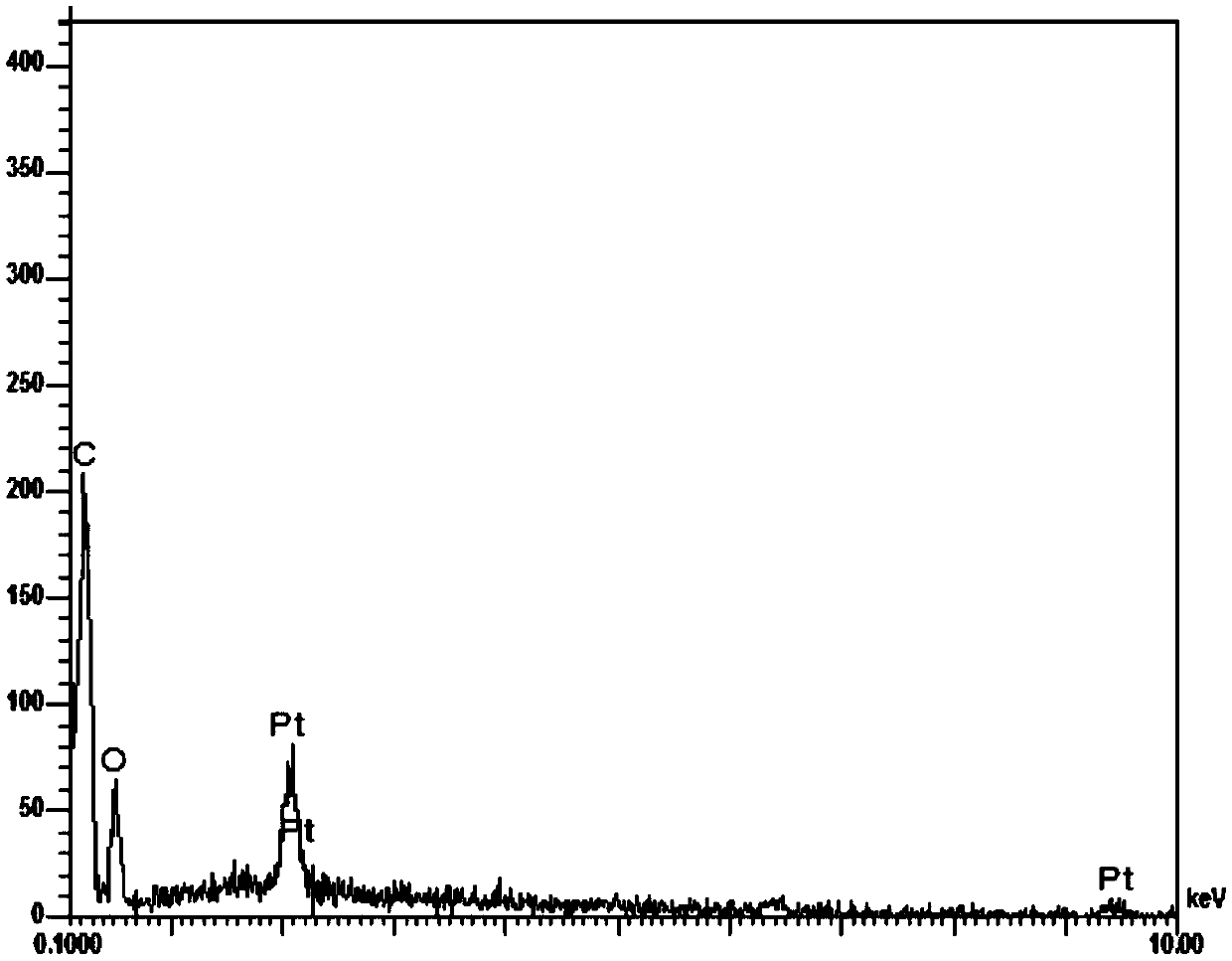

[0065] The present embodiment provides a wood-based-graphene conductive composite material, which is prepared through the following steps:

[0066] (1) Wood pretreatment and extraction process: use 95°C deionized water to boil the wood (poplar material) for 2 hours, then perform a one-week saturated water treatment and freeze for 2 days, and then steam the composite material Treated for 2 hours, then frozen for 2 days, then boiled with deionized water, repeated the above process until the color of the liquid after deionized water was boiled was clear and transparent, and finally dried (dried at 103°C for 30 minutes, dried at 80°C for 4h, in Dry at 60°C for 2h under a vacuum of 0.2MPa).

[0067] (2) impregnate the graphene oxide dispersion liquid with a concentration of 3mg / mL into the fast-growing material body pretreated in step (1) under vacuum conditions, adopt a pulsed vacuum method, the vacuum degree is 0.8MPa, and vacuum impregnate for 10 minutes , normal pressure impre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com