Preparation method of high-molecular-weight branched polyethyleneimine

A technology of polyethyleneimine and high molecular weight, which is applied in the field of chemical synthesis, can solve problems such as unfavorable industrial production and complex condition control, and achieve the effect of easy mastery and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A method for preparing high-molecular-weight branched polyethyleneimine, comprising the following steps: in a reaction kettle, sequentially add aliphatic polyamide having a branched structure, distilled water and a catalyst, start stirring, and raise the temperature of the reaction system to 50-60 ℃, use a constant flow pump to drop an aqueous solution of ethyleneimine into the reaction system, and the dropping time is controlled at 3-4 hours. The compound of formula (I) is added dropwise into the system until the reaction product has a viscosity of 300mpa.s-500mpa.s, kept at 50-60°C for 30-40 minutes, and then cooled to obtain high molecular weight branched polyethyleneimine.

[0022] The aliphatic polyamide with branched structure is prepared by polycondensation reaction of polyamine and dibasic organic carboxylic acid, and the molar mass of the aliphatic polyamide with branched structure is Mw=5000-8000. The polyamine is one or a combination of two or more of trietha...

Embodiment 1

[0034] The preparation method of high molecular weight branched polyethylenimine (A1), comprises the steps:

[0035] (1) Preparation of aliphatic polyamide with branched structure——PA1

[0036] According to adipic acid: diethylenetriamine: the mol ratio of deionized water=1:1.1:3, diethylenetriamine and deionized water are dropped in the reactor, add adipic acid in 6 times in the reactor, During the process of adding adipic acid, control the temperature of the reactor to not exceed 70°C. After the addition, start to heat up and dehydrate. The reaction temperature is controlled at 170-200°C. Slowly add a certain amount of deionized water into the reaction kettle, stir and discharge evenly to obtain an aqueous solution of aliphatic polyamide with a solid content of 60% and a branched structure, which is denoted as PA1.

[0037] GPC (reverse osmosis gel chromatography) detection, Mw = 5000.

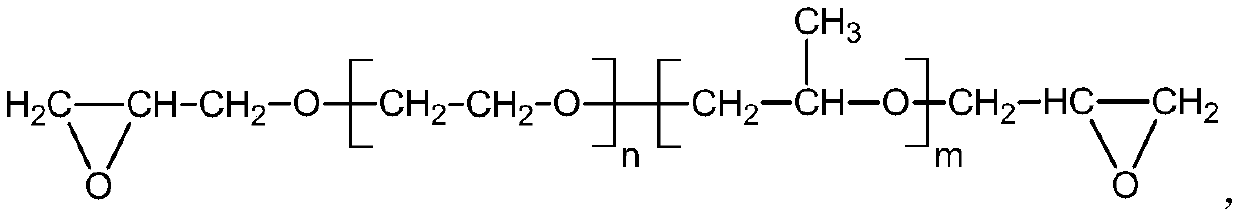

[0038] (2) The compound of formula (I) is

[0039]

[0040] Wherein n=20, m=10, Mw...

Embodiment 2

[0046] The preparation method of high molecular weight branched polyethylenimine (A2), comprises the steps:

[0047] (1) Preparation of aliphatic polyamide with branched structure——PA1

[0048] Preparation method is the same as embodiment 1

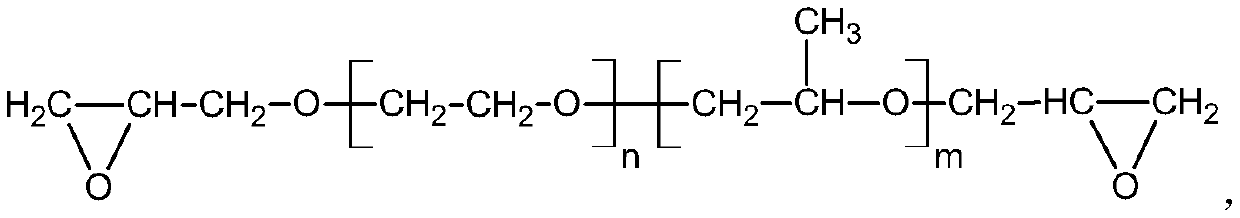

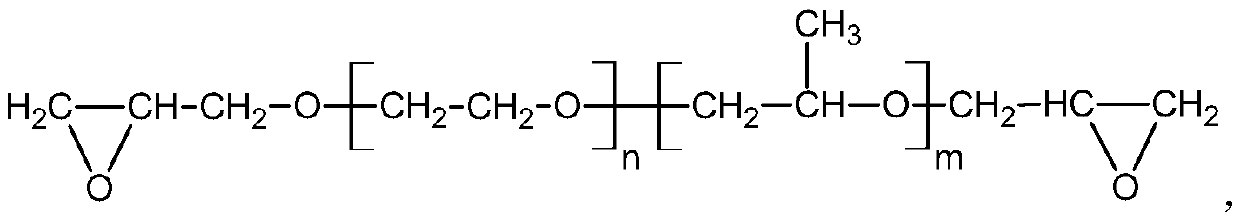

[0049] (2) The compound of formula (I) is

[0050]

[0051] Among them, n=30, m=30, Mw=3000, recorded as KF-30

[0052] (3) Preparation of high molecular weight branched polyethylenimine

[0053]In the reaction kettle, add 800g (amine group content 0.3mol) PA1, 160g distilled water and 10g concentrated sulfuric acid, start stirring, raise the temperature of the reaction system to 50-60°C, and drop 250g of 50wt into the reaction system with a constant flow pump % ethyleneimine aqueous solution (the content of ethyleneimine is 3mol), the dropwise addition time is controlled at 3-4 hours, and the temperature is kept at 50-60° C. for 1 hour after the dropwise addition is completed. Then use the constant flow pump to drip the KF-30 aque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com