High-viscosity disinfection laundry detergent and preparation method thereof

A laundry detergent and high viscosity technology, applied in the field of daily chemical washing, can solve the problems of failing to find a method for increasing the viscosity of disinfection products, reducing the detergency and bactericidal power, and difficult to increase the viscosity of non-ionic systems, and achieving excellent thickening. effect, improving detergency, and good viscosity-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

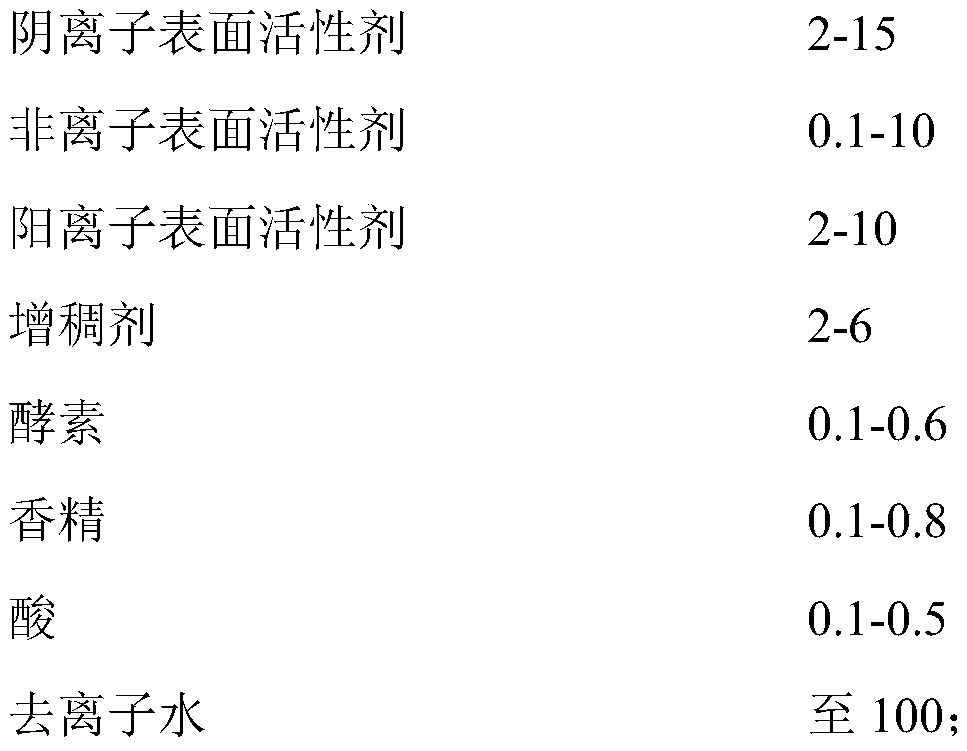

[0029] This embodiment provides a kind of high-viscosity disinfectant laundry liquid, raw material comprises fatty alcohol polyoxyethylene ether sodium carboxylate (AEC-9Na), fatty alcohol polyoxyethylene (7) ether (AEO-7), fatty alcohol polyoxyethylene Ethylene (9) ether (AEO-9), lauryl amidopropyl dimethyl betaine, N,N-didecyl-N,N-dimethyl ammonium chloride (2280), polyhexamethylene biguanide Salt (IB), cocamidomethyl, cellulase, essence, citric acid and deionized water, the parts by weight of each raw material are:

[0030]

[0031]

[0032] The preparation method of described disinfecting laundry detergent is:

[0033] (1) Add deionized water with a total water content of 65% and a temperature of 50°C to 60°C in the reaction kettle, then add anionic surfactant, stir to dissolve, then add nonionic surfactant, zwitterionic surfactant, and stir Dissolved to obtain a mixed solution;

[0034] (2) When the temperature of the mixed solution drops below 40°C, add cationic ...

Embodiment 2

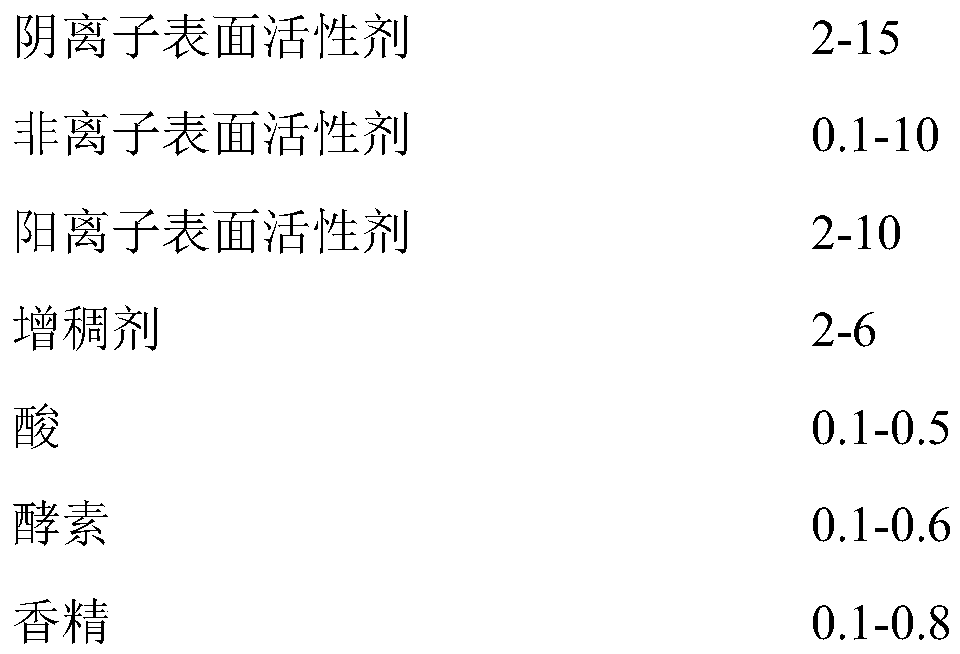

[0036] This embodiment provides a high-viscosity disinfectant laundry detergent, the raw materials include modified grease ethoxylate sulfonate, alkyl glycoside, oxidized lauryl amidopropyl dimethylamine, N,N-didecyl-N , N-dimethylammonium chloride (2280), polyhexamethylene biguanide hydrochloride (IB), cocamide methyl cellulase, essence, citric acid and deionized water, the parts by weight of each raw material for:

[0037]

[0038] The preparation method of described disinfecting laundry liquid refers to Example 1.

Embodiment 3

[0040] The present embodiment provides a kind of high-viscosity disinfectant laundry liquid, and raw material comprises fatty alcohol polyoxyethylene ether carboxylate sodium (AEC-9Na), modified grease ethoxylate sulfonate, fatty alcohol polyoxyethylene (7) Ether (AEO-7), Alkyl Glycoside, Lauramidopropyl Dimethyl Betaine, N,N-Didecyl-N,N-Dimethyl Ammonium Chloride (2280), Lauryl Dimethyl Benzyl ammonium chloride (1227), polyhexamethylene biguanide hydrochloride (IB), methyl glucose dioleate, cellulase, essence, hydrochloric acid and deionized water, the parts by weight of each raw material are :

[0041]

[0042] The preparation method of described disinfecting laundry liquid refers to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com