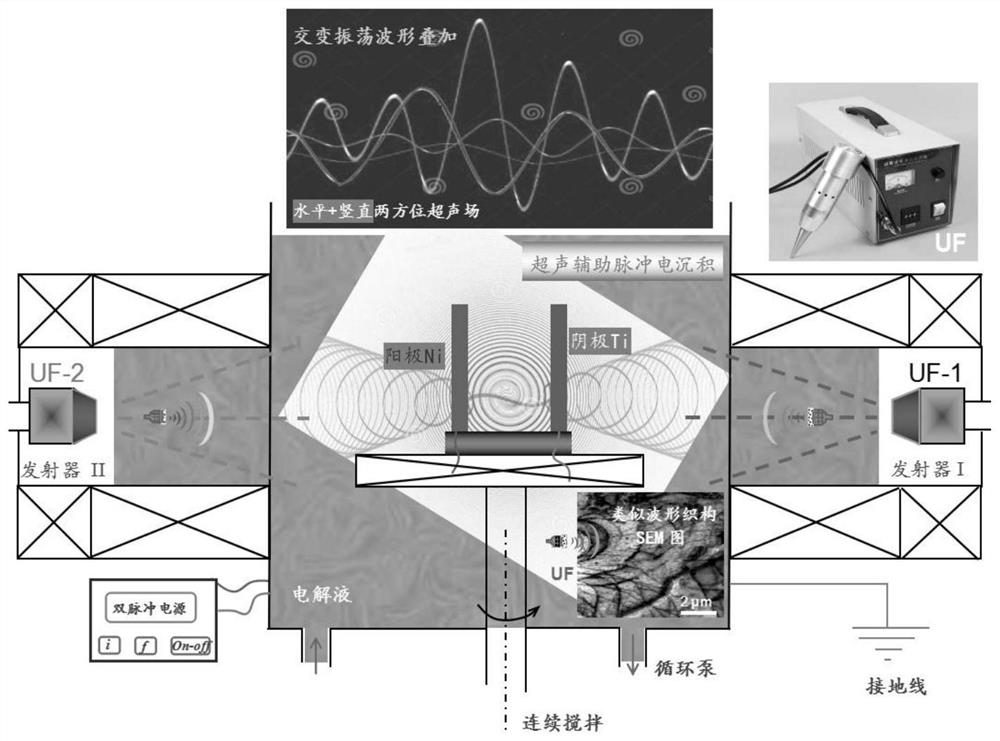

A Method for Controlling the Growth of Nanocrystalline Texture Using Alternating Ultrasonic Frequency

An ultrasonic frequency, nanocrystalline technology, applied in coatings, surface reaction electrolytic coatings, electrolytic coatings, etc., can solve the problems of small-angle grain boundaries, pitting corrosion, deposition rate decline, etc., to achieve simple process, convenient operation, Routing flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

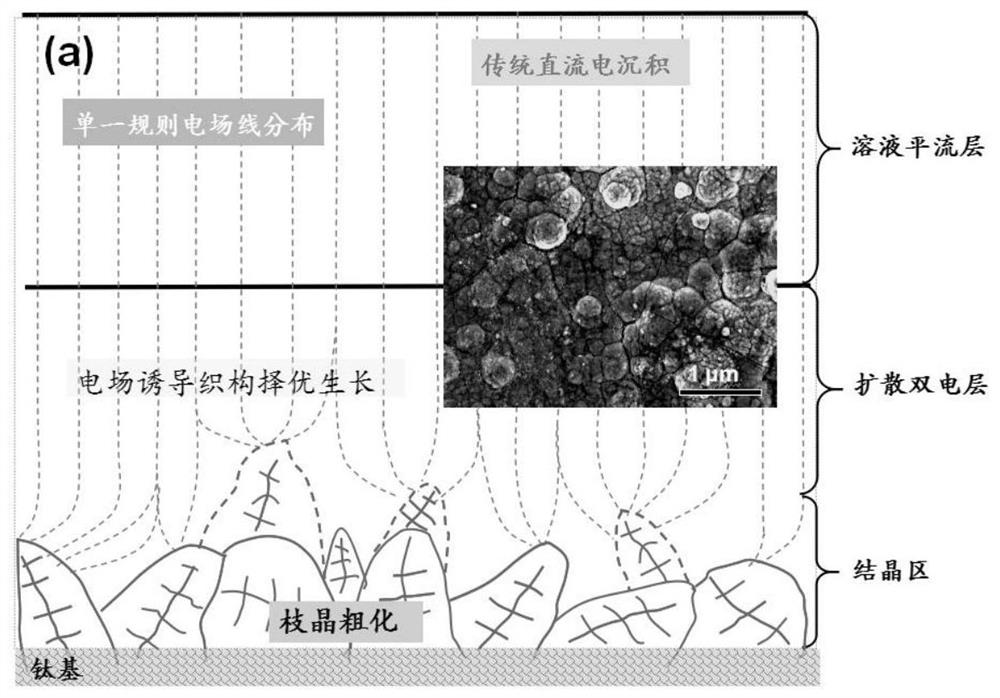

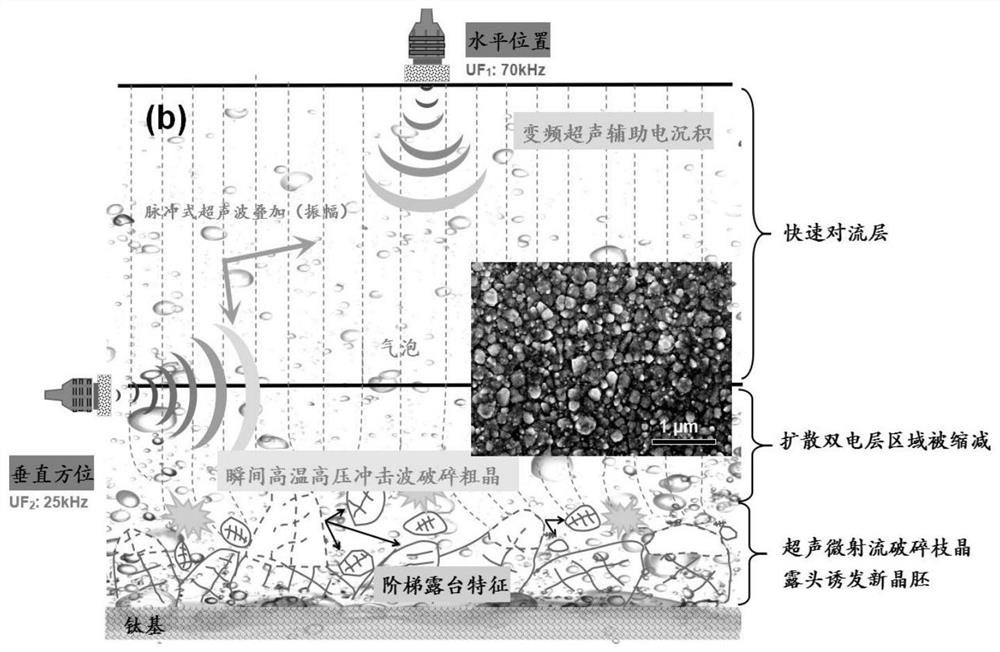

Method used

Image

Examples

Embodiment

[0021] (1) The 5mm×2mm×1mm99.5% high-purity Ti substrate is made of Al 2 o 3 The polishing paste is used for mirror polishing, and the metallographic microscope observes the surface until there are no scratches. The polished Ti substrate is placed on a surface containing NaOH and Na 2 CO 3 Ultrasonic grease treatment in the hot lye solution, the treatment temperature is 90 ° C, after sufficient ultrasonic oscillation, wash with deionized water, dry for later use;

[0022] (2) Place the treated Ti substrate in a place containing 5wt.% H 3 PO 4 HCl-H 2 SO 4 Anodizing is carried out in mixed acid system, in which: 370g / L H 2 SO 4 , 62g / L HCl, 0.5g / L SDS active agent, the rest of the deionized water, ice pack constant temperature water bath about 10 ℃. DC power supply, the initial voltage is 150V, the current rises and then drops rapidly to a steady state, about 0.1mA / cm 2 , so that a honeycomb surface structure with an average pore diameter of 300nm appears on the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com