DNA hybrid catalyst/MOFs composite material and preparation and application thereof

A composite material and catalyst technology, which is applied in the preparation of carbon-based compounds, organic compound/hydride/coordination complex catalysts, organic compound preparation, etc. It can solve the problems of deactivation, variability, and complicated preparation of immobilized materials. , to achieve good high temperature resistance, good resistance to organic solvents, and increase the value of recycling and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1G4

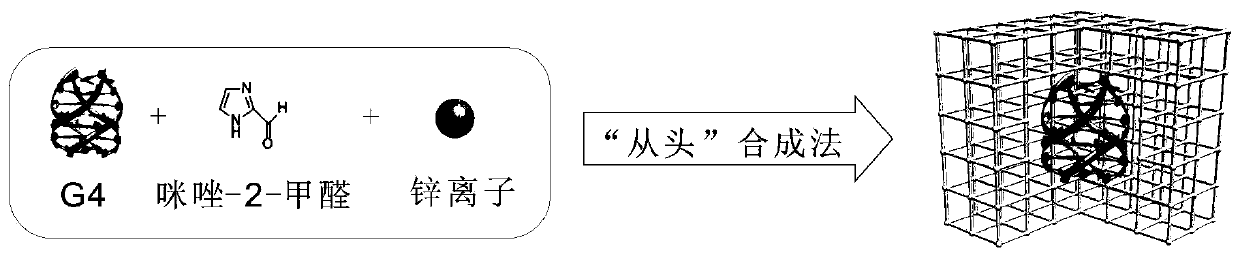

[0073] Preparation of Example 1G4DNA / MOFs composite material (G4DNA@ZIF-90)

[0074] (1) Mix the buffer of single-stranded DNA rich in guanine G with potassium chloride KCl buffer and hemin Hemin buffer to obtain the DNA hybrid catalyst G4DNA;

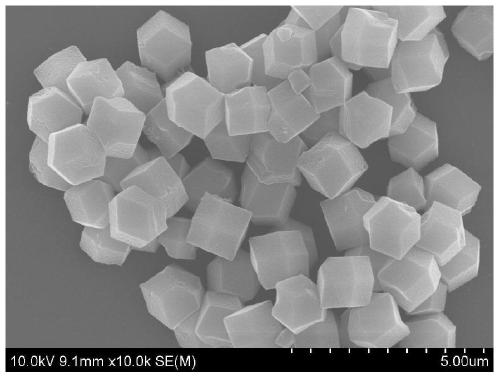

[0075] (2) the aqueous solution of the G4DNA that step (1) obtains, imidazole-2-formaldehyde is mixed with the aqueous solution of zinc nitrate (synthetic method reaction mechanism diagram is as follows figure 1 shown), to obtain the DNA hybrid catalyst / MOFs composite material, the SEM image of the G4DNA / MOFs composite material is shown in figure 2 shown.

Embodiment 2

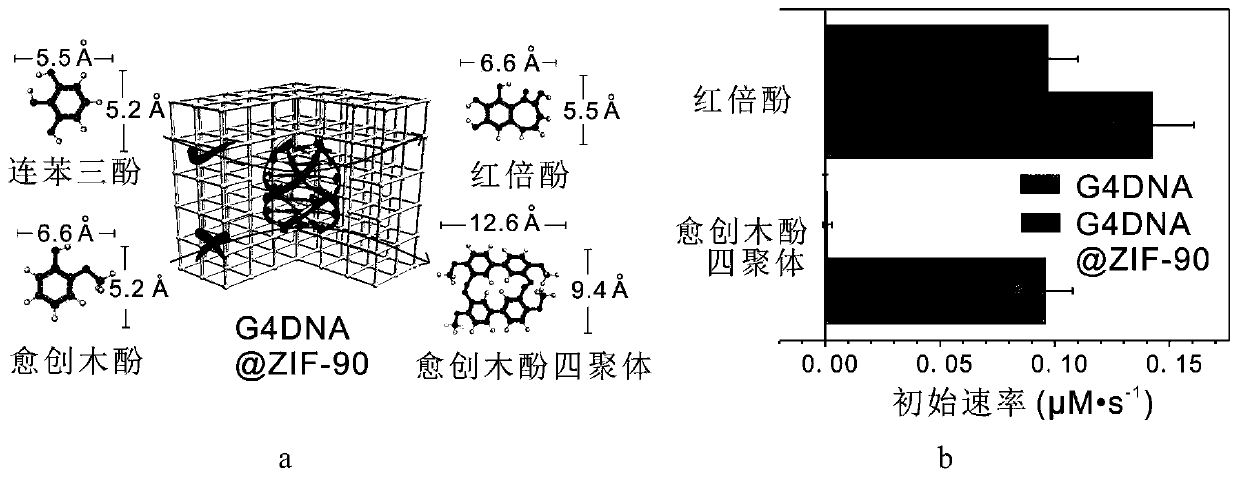

[0076] Example 2G4DNA / MOFs Composite Material Size Selective Catalysis of Pyrogallol and Guaiacol

[0077] Detect the catalytic activity of the G4DNA / MOFs composite material (G4DNA@ZIF-90) prepared in Example 1 of the present invention in aqueous solution:

[0078] H 2 o 2 (1.9 mM) was added to 1 mL Tris-HCl buffer (10 mM, pH=7) containing about 4 mg G4DNA@ZIF-90 and 10 mM pyrogallol (THB) or 10 mM guaiacol to initiate the reaction. Measure the absorbance value of the supernatant product at various time points of the reaction using a UV-Vis spectrophotometer, as image 3 The initial rate diagram of the product shown in b shows that the molecular sizes of pyrogallol and guaiacol are relatively small and similar. Using pyrogallol as a substrate, the initial rate of pyrogallol to catalyzed red bisphenols by G4DNA@ZIF-90 is about It is 68% of free G4DNA catalysis; and use guaiacol as substrate and no product is observed, this is because the molecular size of the catalyzed produ...

Embodiment 3

[0079] Example 3G4 The activity of DNA / MOFs composite materials in different catalytic cycles, and the recovery of activity after soaking in different solutions

[0080]Detect the catalytic activity recovery ability of the G4DNA / MOFs composite material (G4DNA@ZIF-90) prepared in Example 1 of the present invention in aqueous solution: as Figure 4 a shows the comparison of the relative activities of G4DNA / MOFs composites for catalyzing pyrogallol (I represents the first catalytic cycle; II represents the second catalytic cycle; III represents the third catalytic cycle); after three catalytic cycles , the catalytic activity of G4DNA@ZIF-90 dropped to about 20% of the initial activity. The G4DNA@ZIF-90 particles with reduced activity were immersed in Tris-HCl buffer solution at 88 °C, and after cooling, the solids were sequentially soaked to K + and Hemin buffer solution, the activity recovery step is the same as the synthesis process of G4DNA. After treatment, G4DNA@ZIF-90 rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com