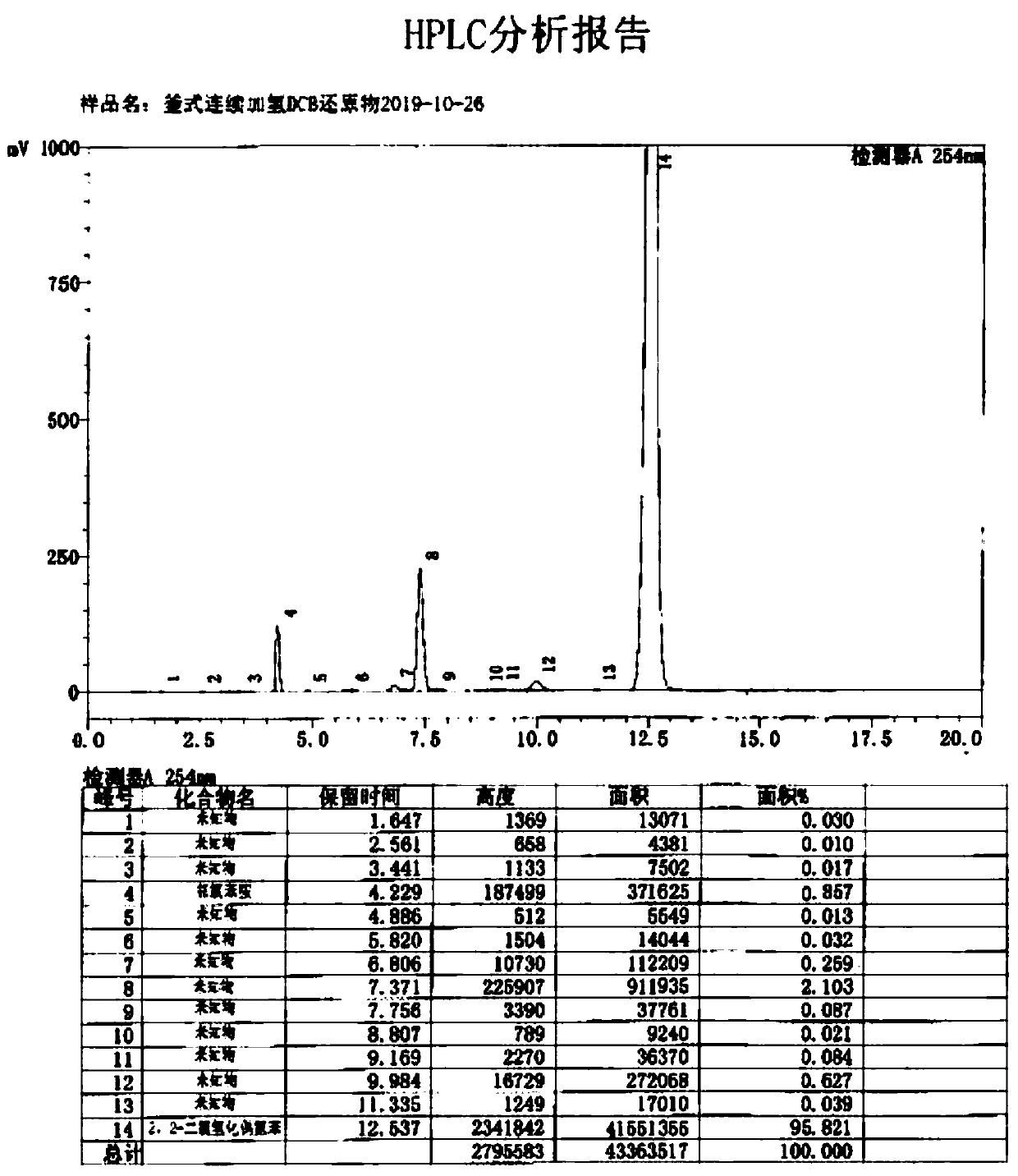

Method for preparing DCB reduzate through continuous catalytic hydrogenation reduction

A catalytic hydrogenation and catalyst technology, which is applied in the preparation of hydrazine, chemical recovery, organic chemistry, etc., can solve the problems of unstable reaction control, toluene-containing waste gas emission, and large volume of the reactor, so as to achieve internal recycling and reduce by-products Fewer, more selective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

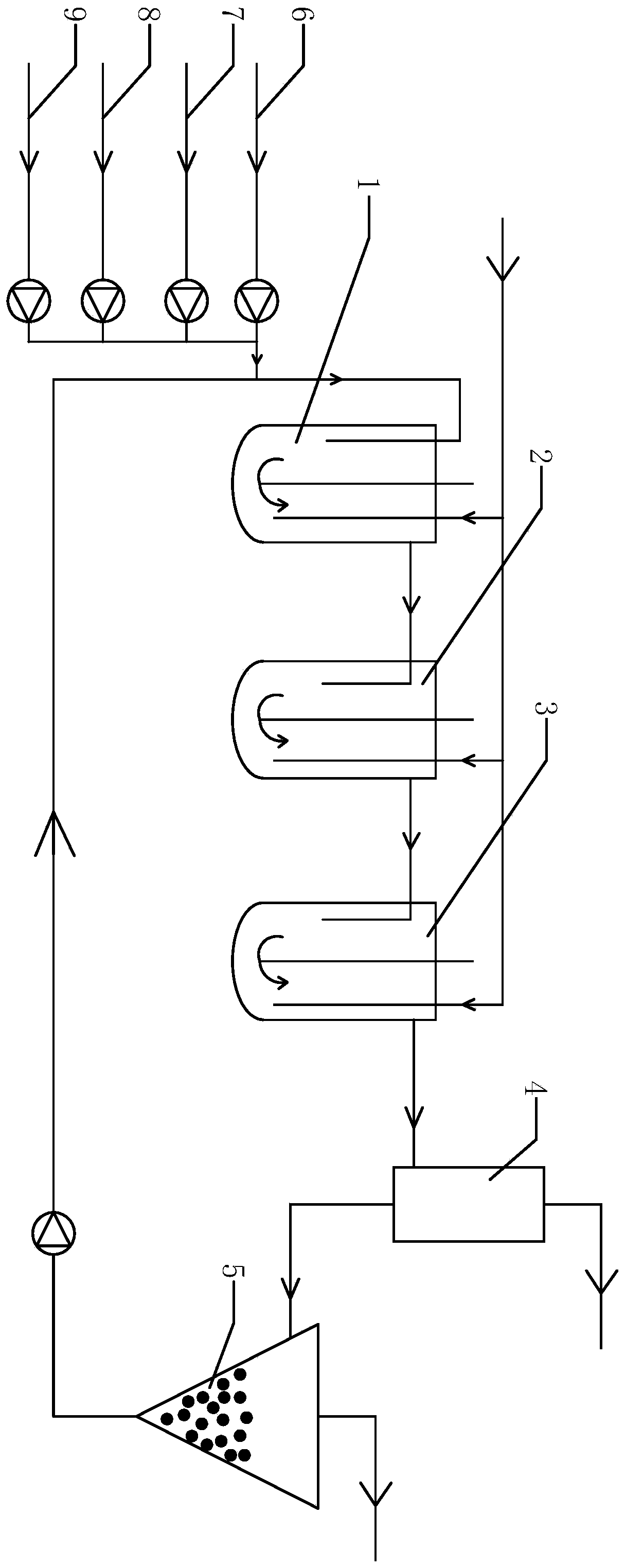

[0032] Add 600g of adjacent reactors to 3 2L continuous reactors connected in series (divided into the first-stage reactor / reactor, the second-stage reactor / reactor, and the third-stage reactor / reactor according to the order in series) Nitrochlorobenzene, 720g toluene, 250g 30% liquid caustic soda, 204g desalinated water and 6g 1% Pt / C catalyst, replace the air with nitrogen twice, and then replace the nitrogen with hydrogen twice, start stirring, and heat the reaction mass to 90 ℃, continuously feed hydrogen, control the hydrogen pressure at 1MPa, control the reaction temperature at 90-95 ℃, until all the three reactors react without absorbing hydrogen, the first stage of the intermittent reaction ends, and the substrate preparation for the continuous reaction is completed;

[0033] After the completion of the first step reaction, open the overflow feed valves of 3 kettle-type reactors, and pump o-nitrochlorobenzene, toluene, 30% liquid caustic soda and For desalted water, th...

Embodiment 2

[0038] 600g of o-nitrochlorobenzene, 720g of toluene, 250g of 30% liquid caustic soda, 204g of desalinated water and 4g of 1% Pt / C catalyst were added to three series-connected 2L kettle-type continuous reactors respectively, and the air was replaced with nitrogen for two times. After replacing the nitrogen with hydrogen twice, start stirring, heat the reaction mass to 90°C, continuously feed hydrogen, control the hydrogen pressure at 1.5MPa, and control the reaction temperature at 90-95°C until all the three reactors react without absorbing hydrogen. , the first stage of the batch reaction ends, and the substrate preparation of the continuous reaction is completed;

[0039]After the completion of the first step reaction, open the overflow feed valves of 3 kettle-type reactors, and pump o-nitrochlorobenzene, toluene, 30% liquid caustic soda and For desalted water, the feed rate of o-nitrochlorobenzene is 100g / h, the feed rate of toluene solvent is 120g / h, the feed rate of 30% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com