Preparation method of sodium taurate

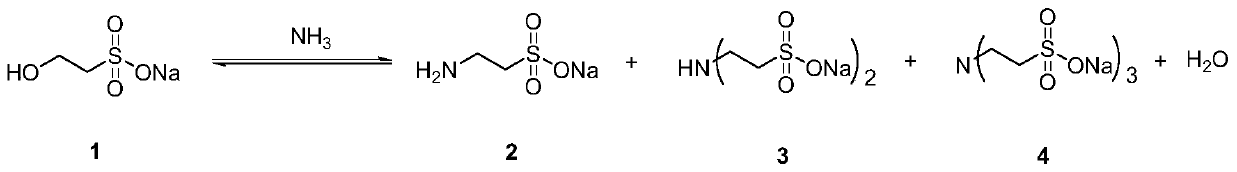

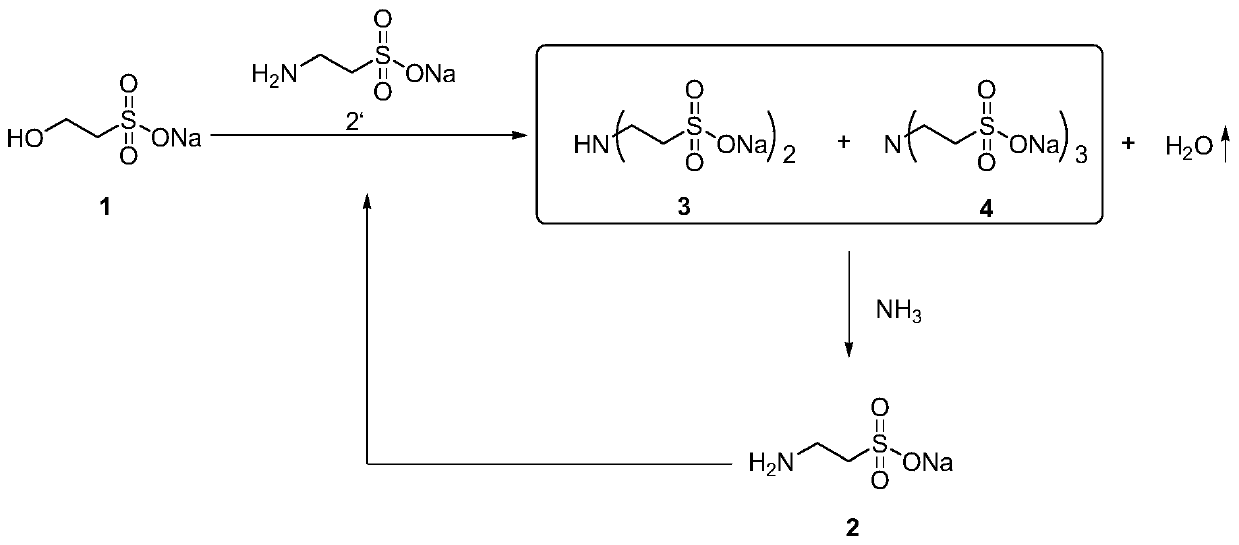

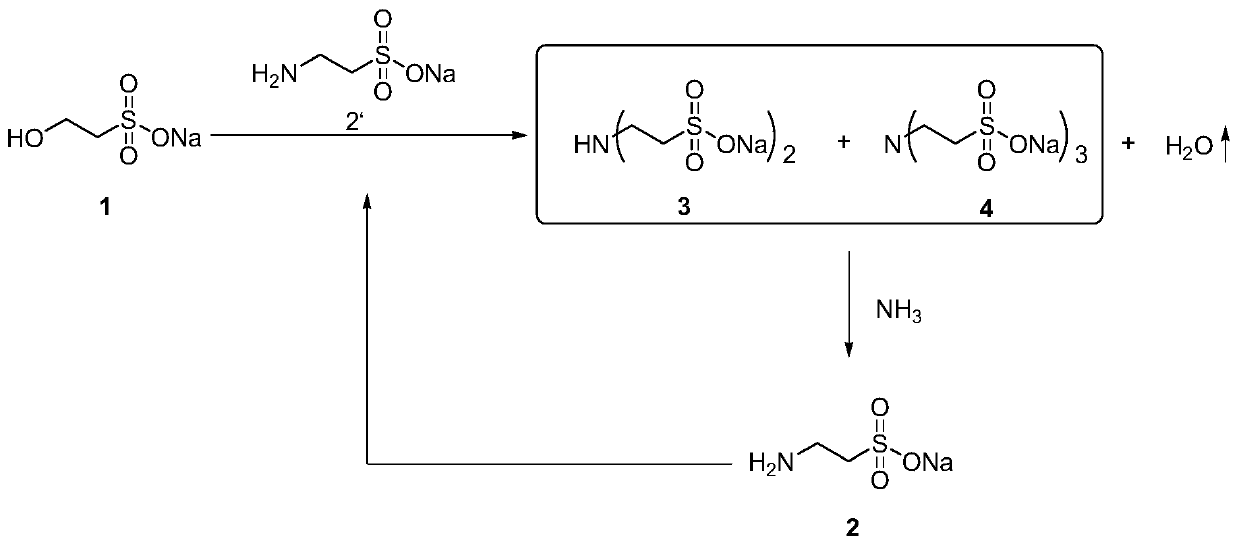

A technology of sodium taurine and sodium isethionate, which is applied to the preparation of sulfonic acid, sulfonate, and organic compounds, and can solve problems such as difficult separation, difficult online separation, and large ammonia usage. Achieve the effects of reducing dosage, increasing yield and improving conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The preparation of embodiment 1 sodium taurate

[0050] The structural formula of the ionic liquid used in this embodiment is:

[0051]

[0052] In a 0.5L reactor, add 100g of the above-mentioned ionic liquid, then add 50g of sodium taurate and 55g of sodium isethionate, raise the temperature to 60°C, control the pressure of the reaction system to 2Kpa, keep stirring for 2 hours, and then naturally cool down to room temperature. The ionic liquid solution of sodium ditaurate / sodium tritaurate is obtained.

[0053] Chromatographic analysis shows that the mass ratio of sodium isethionate, (sodium ditaurate+sodium tritaurate) is 0.09:99.8, that is, the quality of unreacted sodium isethionate is product ditaurine 0.09% of the total mass of sodium and sodium tritaurate.

[0054] Water Content Analysis Test The water content in the ionic liquid solution was 0.03%.

[0055] Mass spectrometry results:

[0056] Sodium Ditaurate HRMS(ESI)m / z[M] 2- :[C 2 h 9 NO 6 S 2 ] ...

Embodiment 2

[0061] The preparation of embodiment 2 sodium taurine

[0062] The structural formula of the ionic liquid used in this embodiment is:

[0063]

[0064] In a 1L reaction kettle, add 200g of the above-mentioned ionic liquid, then add 50g of sodium taurate and 75g of sodium isethionate, raise the temperature to 180°C, control the pressure of the reaction system to 5Kpa, keep stirring for 2 hours, and naturally cool down to room temperature to obtain Ionic liquid solution of sodium ditaurate / sodium tritaurate.

[0065] Chromatographic analysis shows that the mass ratio of sodium isethionate, (sodium ditaurate+sodium tritaurate) is 0.08:99.91, that is, the quality of unreacted sodium isethionate is product ditaurine 0.08% of the total mass of sodium and sodium tritaurate.

[0066] Water Content Analysis Test The water content in the ionic liquid solution was 0.02%.

[0067] Pass into 23g liquid ammonia in the ionic liquid solution (wherein, the total mass of di-sodium taurate...

Embodiment 3

[0069]The preparation of embodiment 3 sodium taurine

[0070] The structural formula of the ionic liquid used in this embodiment is:

[0071]

[0072] In a 1L reaction kettle, add 250g of the above-mentioned ionic liquid, then add 50g of sodium taurate and 90g of sodium isethionate, raise the temperature to 220°C, control the pressure of the reaction system to 5Kpa, keep stirring for 4 hours, and naturally cool down to room temperature to obtain Ionic liquid solution of sodium ditaurate / sodium tritaurate.

[0073] Chromatographic analysis shows that the mass ratio of sodium isethionate, (sodium ditaurate+sodium tritaurate) is 0.05:99.92, that is, the quality of unreacted sodium isethionate is product ditaurine 0.05% of the total mass of sodium and sodium tritaurate.

[0074] Water Content Analysis Test The water content in the ionic liquid solution was 0.02%.

[0075] Pass into 17.5g liquefied ammonia in the ionic liquid solution (wherein, the total mass of di-sodium tau...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com