Preparation method of granular diisobutylthiuram disulfide

A granular technology of diisobutyl disulfide, which is applied in the direction of organic chemistry, can solve problems such as non-compliance with environmental protection, energy saving and emission reduction, easy occurrence of viscous substances, long production cycle, etc., and achieve improvement of viscous substances and other problems. The effect of small land area and shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

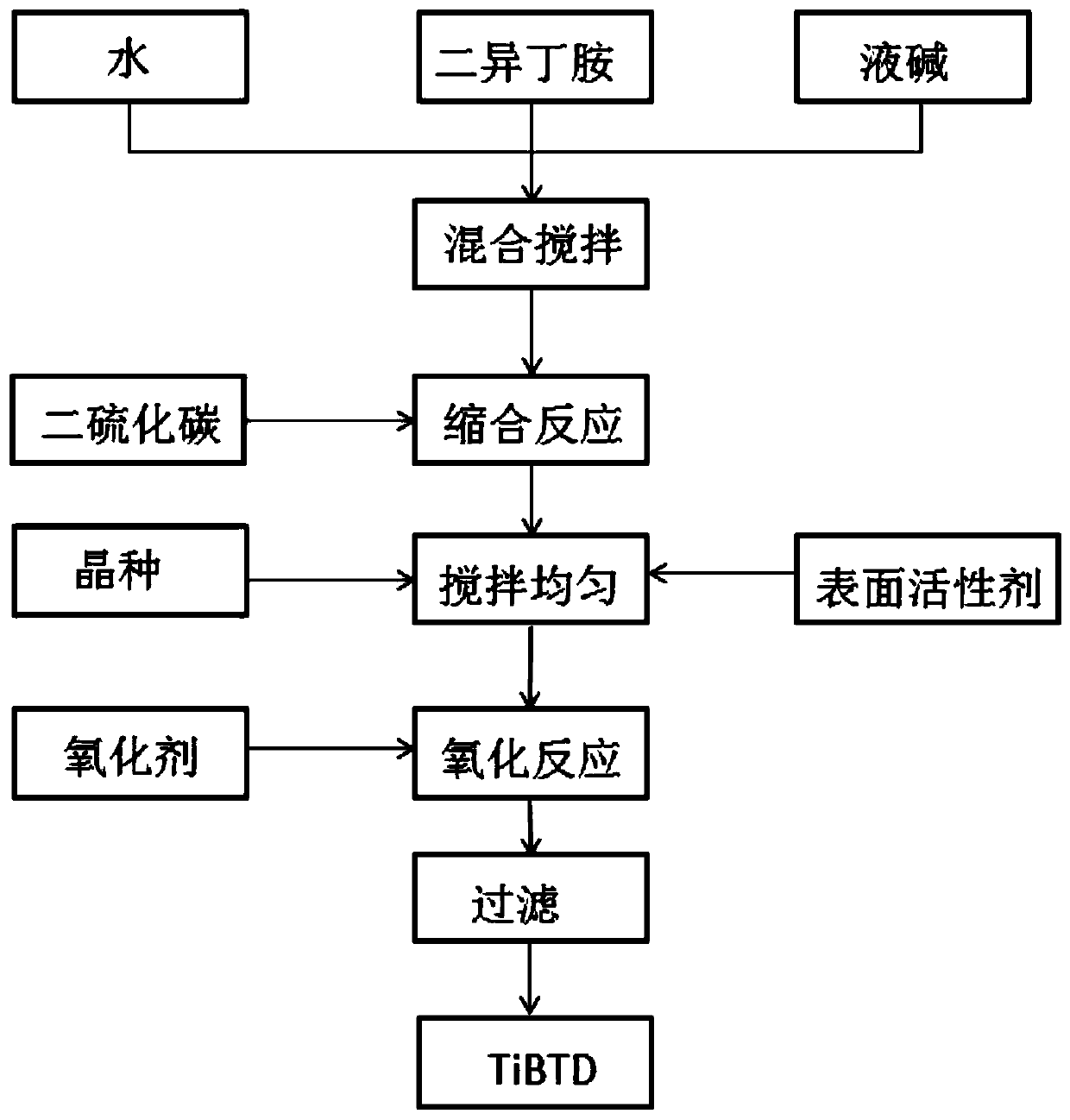

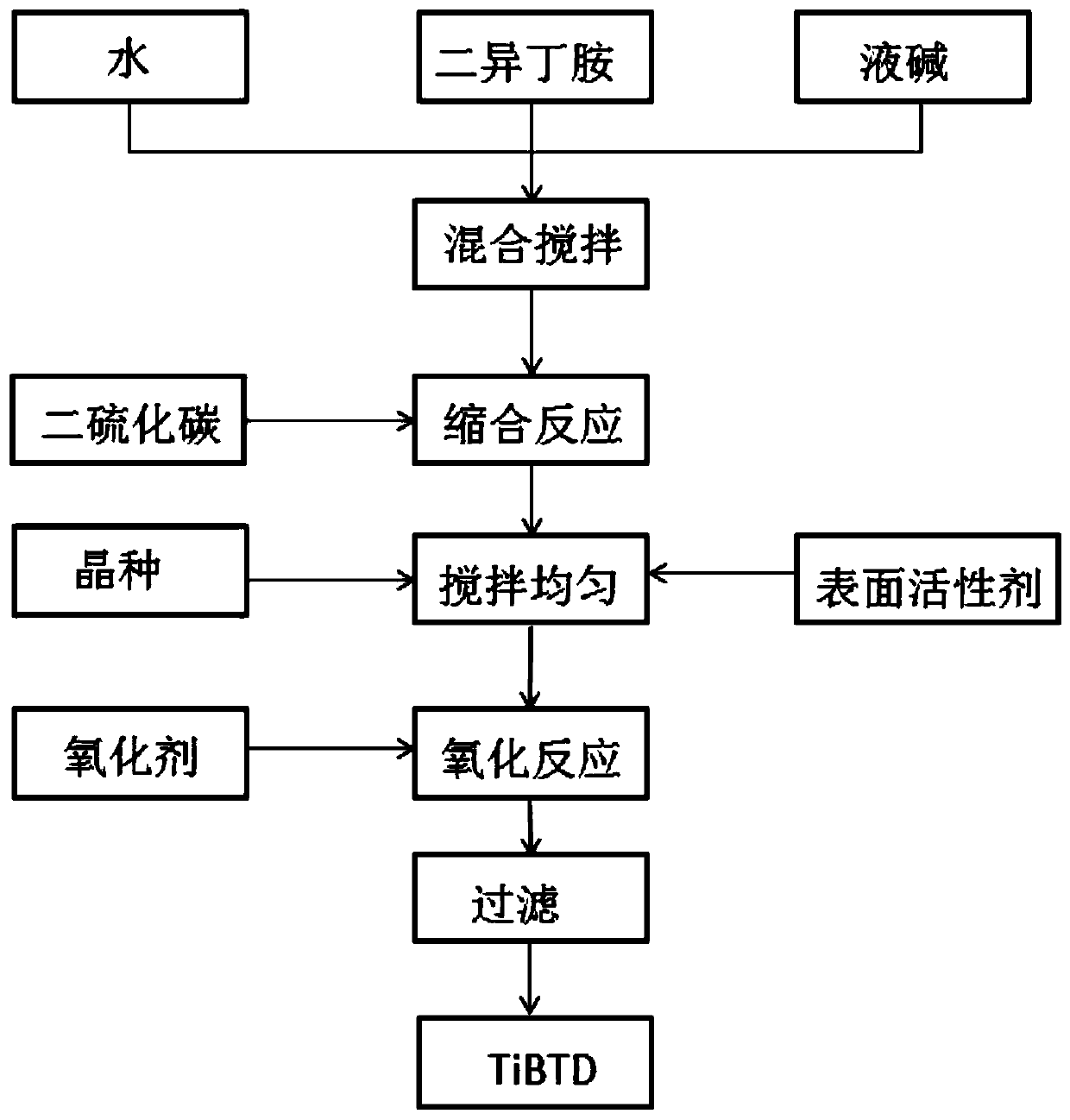

[0032] According to one aspect of the present invention, a preparation method of granular diisobutylthiuram disulfide is provided in at least one embodiment, comprising:

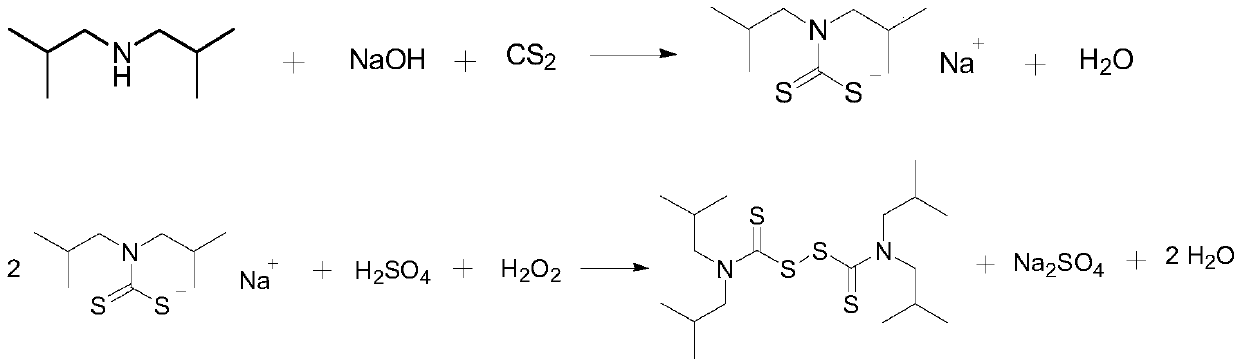

[0033] (a) by diisobutylamine, liquid caustic soda and carbon disulfide mixed reaction, obtain diisobutyl dithiocarbamate sodium solution;

[0034] (b) mixing sodium diisobutyldithiocarbamate solution, seed crystal and surfactant, and the crystal seed comprises diisobutylthiuram disulfide powder;

[0035] (c) mixing the solution obtained in step (b) with H 2 SO 4 and H 2 O 2 The mixed reaction gave granular diisobutylthiuram disulfide.

[0036] The above-mentioned preparation method has been improved in the traditional process. After the mixed reaction of diisobutylamine, liquid caustic soda and carbon disulfide is carried out to obtain the sodium diisobutyl dithiocarbamate solution, it is mixed with crystal seed and surfactant, and finally mixed with the diisobutyl dithiocarbamate solution. The mixed r...

Embodiment 1

[0058] A kind of preparation method of granular diisobutylthiuram disulfide, such as figure 1 shown, including:

[0059] (a) 500g of pure water, 50g of liquid caustic soda and 50g of diisobutylamine were added to a 1000mL reaction flask, and after mixing and stirring, 33g of carbon disulfide liquid was added dropwise at a constant speed for 3h, and the reaction temperature was controlled to be 25°C. After the reaction, two Sodium isobutyl dithiocarbamate solution;

[0060] (b) add 1g TiBTD powder and 0.5g sorbitol fatty acid ester, stir to make diisobutyl dithiocarbamate sodium solution, TiBTD powder and sorbitol fatty acid ester fully mixed;

[0061] (c) take by weighing 150g of pure water, add 20g concentrated sulfuric acid (concentration is 98wt%) and 27g hydrogen peroxide (concentration is 27.5wt%) under stirring to obtain mixed oxidant, uniformly add oxidant dropwise, take 4h, and control the reaction temperature to be 25 ℃, after the reaction is completed, tetraisobuty...

Embodiment 2

[0063] A preparation method of granular diisobutylthiuram disulfide is different from Example 1 in that in this example, sorbitan fatty acid ester is replaced with polysorbate, and the rest are the same as in Example 1. The obtained tetraisobutylthiuram disulfide product was light yellow granules with a yield of 98.6% and an initial melting point of 67.8°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Initial melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com