Elastic epoxy resin coating and preparation method thereof

A technology of epoxy resin coating and epoxy resin, applied in the direction of epoxy resin coating, anti-corrosion coating, polyurea/polyurethane coating, etc., can solve the problems of coating loss of shielding ability, structural corrosion, low elongation, etc., to promote Corrosion science, improved toughness, elasticity and improved elongation at break effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

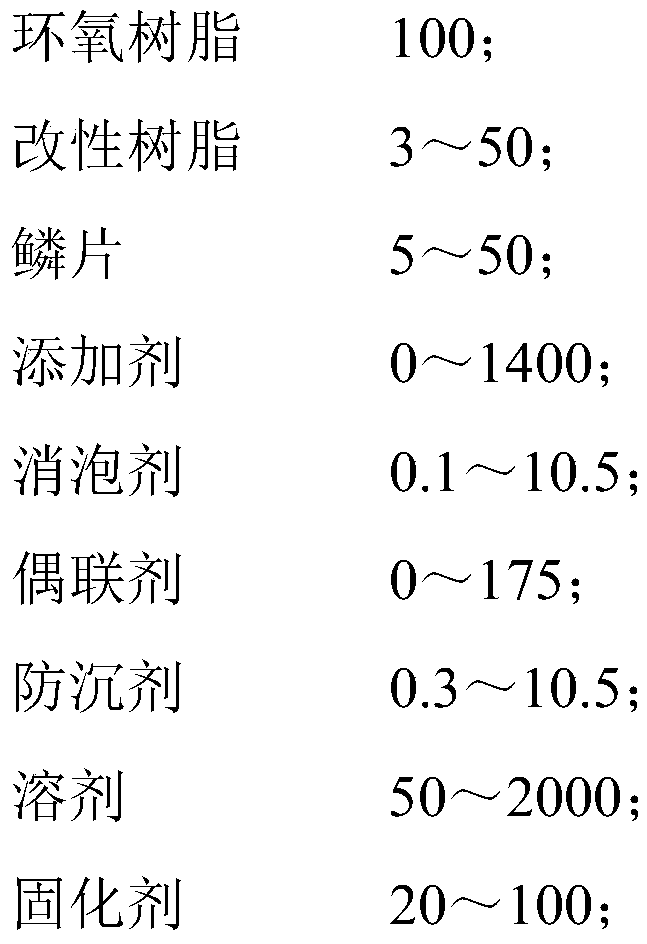

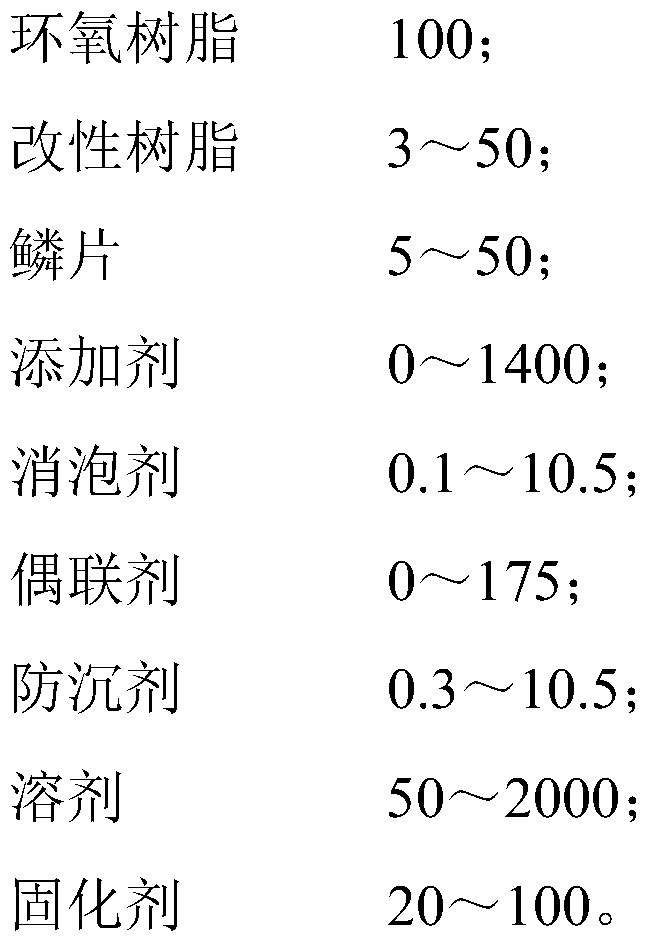

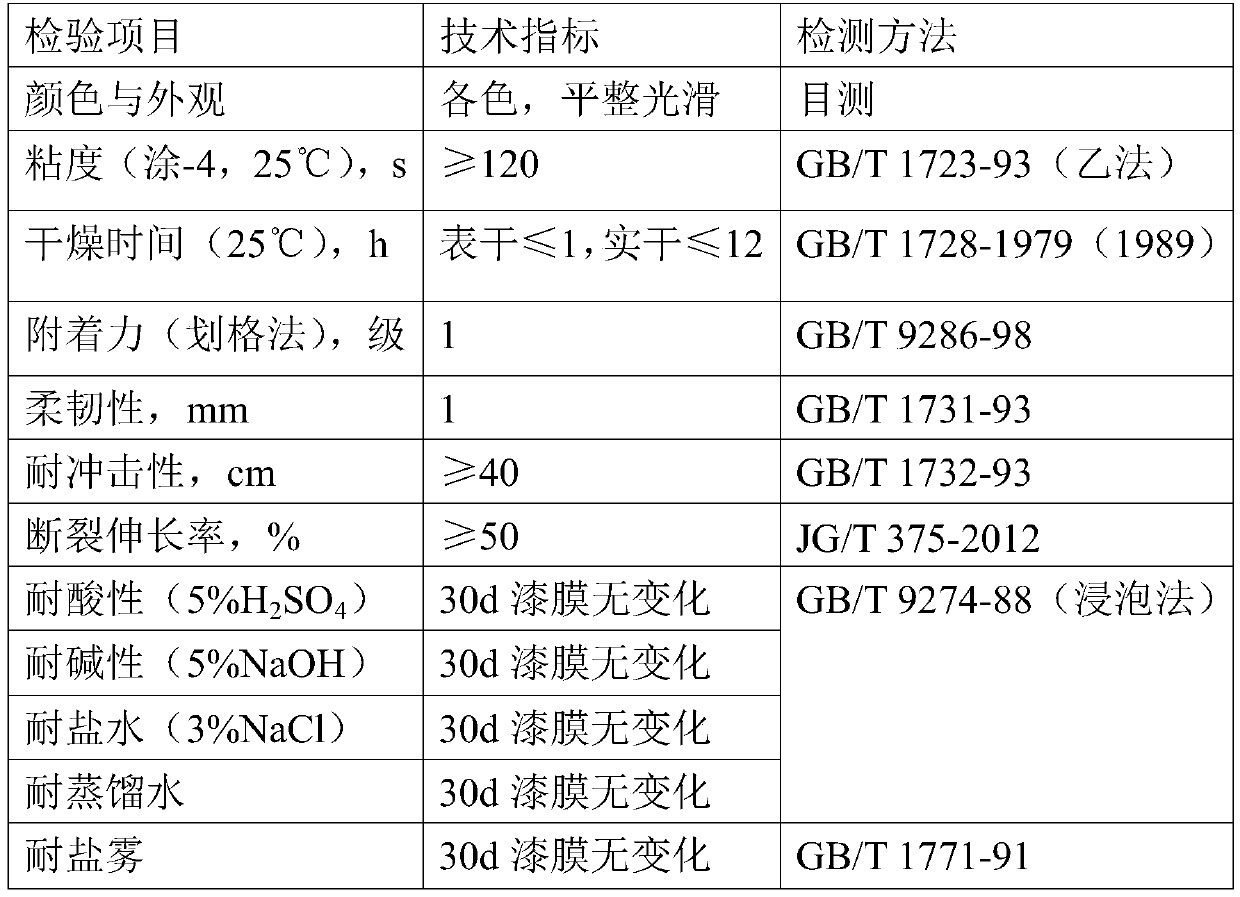

[0029] A kind of elastic epoxy resin coating, its composition proportioning by weight is as follows:

[0030] (1) bisphenol A epoxy resin 100;

[0031] (2) The solvent is xylene 25, butyl acetate 25;

[0032] (3) The modified resin is fluorine rubber 23 resin 15;

[0033] (4) aluminum alloy scales 40;

[0034] (5) Dimethicone 1.5;

[0035] (6) Titanate coupling agent 2.5;

[0036] (7) Fumed silica 1.3;

[0037] (8) Containing NH with a molecular weight of 5000 to 8000 2 Fluorine rubber curing agent 75 (the curing agent is synthesized using fluorine rubber 23).

Embodiment 2

[0039] A kind of elastic epoxy resin coating, its composition proportioning by weight is as follows:

[0040] (1) bisphenol F epoxy resin 100;

[0041] (2) Solvent is methyl acetate 10, cyclohexanone 5, dimethyl carbonate 40;

[0042] (3) The modified resin is polyurethane resin 45;

[0043] (4) 80 mesh stainless steel scales 25;

[0044] (5) Pigments and fillers are talcum powder 10, mica powder 80, titanium dioxide 90, chrome yellow 15, carbon black 10.5;

[0045] (6) Dimethicone 2.5;

[0046] (7) Organic bentonite 2.5;

[0047] (8) Containing NH with a molecular weight of 12,000 to 15,000 2 Fluorine rubber curing agent 95 (the curing agent is synthesized using fluorine rubber 246).

Embodiment 3

[0049] A kind of elastic epoxy resin coating, its composition proportioning by weight is as follows:

[0050] (1) bisphenol A epoxy resin 100;

[0051] (2) The solvent is butanone 25, ethylene glycol butyl ether 35;

[0052] (3) The modified resin is fluorine rubber 26 resin 15;

[0053] (4) aluminum alloy scales 40;

[0054] (5) barium sulfate 240;

[0056] (7) Dimethicone 1.5;

[0057] (8) Titanate coupling agent 2.5;

[0058] (9) Fumed silica 1.3;

[0059] (10) Containing NH with a molecular weight of 5000 to 8000 2 Fluorine rubber curing agent 75 (the curing agent is synthesized using fluorine rubber 26).

[0060] The concrete preparation method of embodiment 1, embodiment 2, embodiment 3 is the same. First, weigh each component according to the weight ratio of each example, and then prepare component A and component B respectively. When using, just mix component A and component B directly. in,

[0061] Preparation of component A: firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com