Structure and method for improving thermal stability and reliability of ohmic contact of N polar surface GaN

A technology of ohmic contact and thermal stability, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of device performance degradation, ohmic contact characteristic deterioration, photolithography deviation, etc., to achieve high repeatability and reliability, reduce Effect of specific contact resistivity and improvement of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that the following examples are based on the premise of this technical solution, and provide detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the present invention. Example.

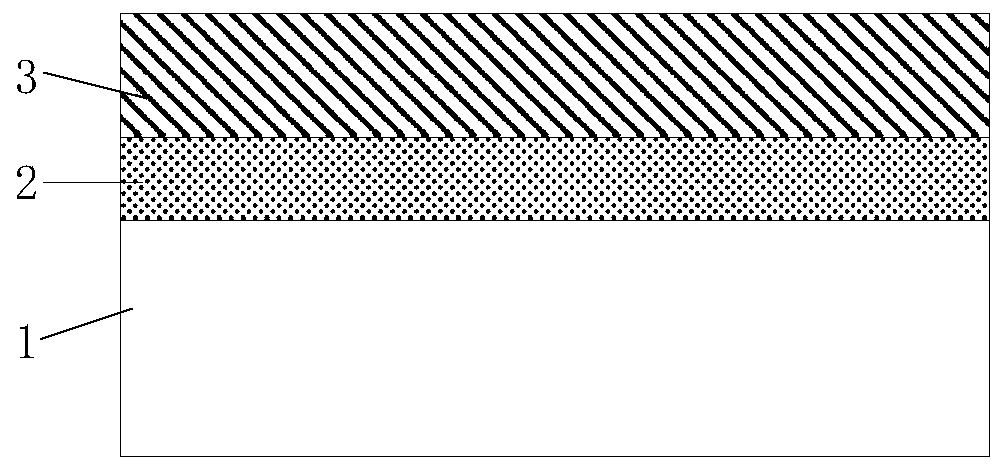

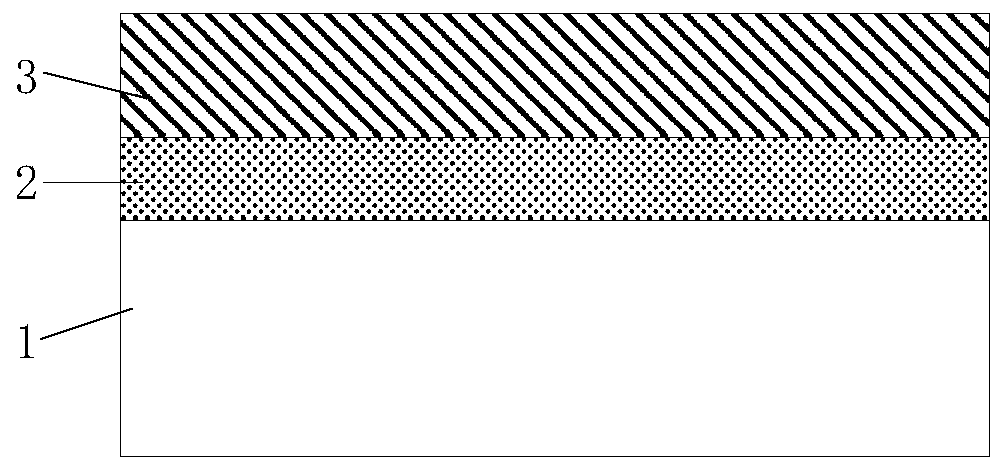

[0029] Such as figure 1 As shown, the present invention is a structure for improving the ohmic contact performance of GaN on the N polar plane, said structure comprising a GaN material, a TiN thin layer ( 2), and a metal stack (3) covering the TiN thin layer (2).

[0030] Preferably, the GaN epitaxial layer (1) is a GaN epitaxial layer (1) with an N polar surface and unintentionally doped, and the thickness of the GaN epitaxial layer (1) is 10nm-500μm

[0031] Preferably, the thickness of the TiN thin layer is 1-100 nm.

[0032] Preferably, the metal in the metal stack (3) is a non-Au metal compatible w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Specific contact resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com