High-first-effect silicon-based negative electrode material and preparation method thereof

A silicon-based negative electrode material, first-effect technology, applied in negative electrodes, battery electrodes, active material electrodes, etc., can solve the problems of reducing the first Coulomb efficiency, increasing the application cost of lithium ion supply end materials, etc., to improve cycle stability, Reduce build time and cost, and improve the effectiveness of constructing buffer layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Put 0.3gliOH into an agate vacuum tank, add 10ml of absolute ethanol, dissolve it, then add 5g of 5um SiO, then add 25g of zirconium balls, vacuumize and fill with hydrogen-argon mixed gas; perform high-energy ball milling and upper ball milling for 30min , the speed is 500r / min;

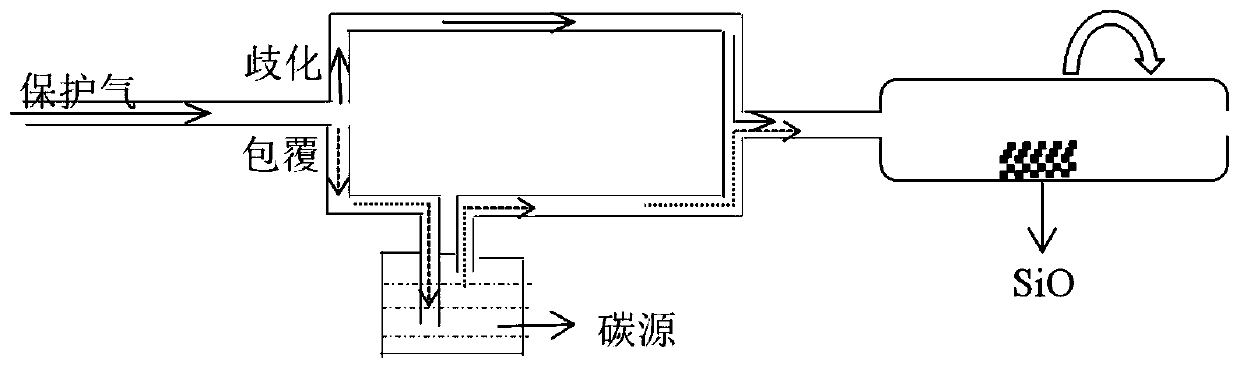

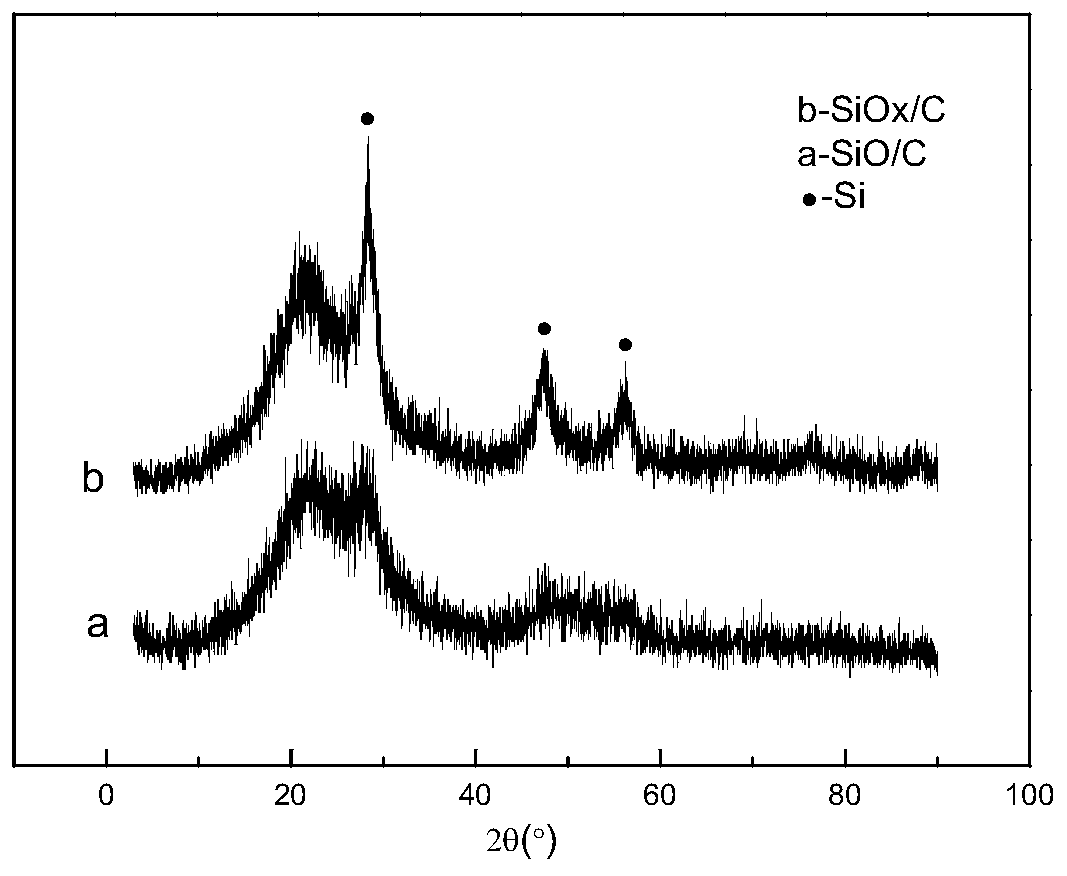

[0037] (2) transfer the above-mentioned material through ball milling to a quartz crucible ( figure 1 The indicated SiO to be reacted) was vacuum-dried and placed in a rotary furnace. Under the protection of Ar, it was raised to 800°C at 5°C / min and then kept for 10min to produce nano-silicon crystal grains for disproportionation reaction ( figure 1 Schematic "disproportionation"); then rise to 900°C at 5°C / min, pass the organic carbon source isopentane into the rotary furnace under the protection gas, adjust the air flow to 150ml / min, and pyrolyze at high temperature for 30min ( figure 1 Schematic "coating"); After the reaction, the protective gas was changed to room temperature;

[0...

Embodiment 2

[0043] (1) Put 0.5gCa(OH)2 into an agate vacuum tank, add 10ml of absolute ethanol, dissolve and then add 5g5um of SiO, then add 25g of zirconium balls, vacuumize and fill with hydrogen-argon mixed gas; And upper ball milling for 30min, the speed is 500r / min;

[0044] (2) Transfer the ball-milled materials to a quartz crucible, put them into a rotary furnace after vacuum drying, raise them to 750°C at 5°C / min under the protection of Ar, and then keep them warm for 30min to produce nano-silicon grains by disproportionation reaction ; Then rise to 800°C at 5°C / min, pass the organic carbon source p-xylene into the rotary furnace under the protection gas, adjust the gas flow to 200ml / min, and pyrolyze at high temperature for 30min; The protective gas is lowered to room temperature;

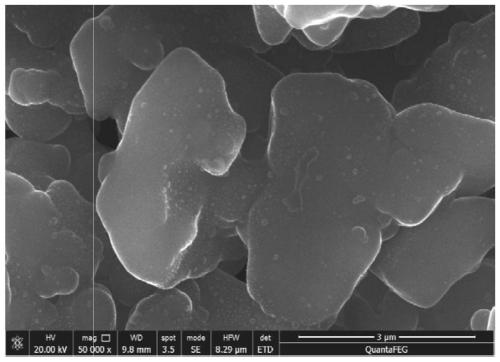

[0045] (3) Put the carbon-coated material into a beaker, add 50ml of 1M HCl, stir and wash for 10min, wash with deionized water until neutral, and vacuum dry to obtain the SiOx / C negative electrode m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com