Co-doped FeNCN/C as well as preparation method and application thereof

An iron salt and organic acid technology, applied in the field of electrochemistry, can solve the problems of harsh preparation environment and complex synthesis process, and achieve the effects of simplifying the preparation process, good energy storage performance, and fast charging and discharging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of Co-doped FeNCN / C includes the following steps:

[0028] 1) Add 1.0 g analytically pure urea, 1.0 g ferric ammonium oxalate, and 0.1 g cobalt acetate tetrahydrate into 10 mL of deionized water, stir for 1 h to form a complex of iron salt and cobalt salt, labeled A;

[0029] 2) Freeze solution A at -30°C for 2 h, and then dry it in a vacuum freeze dryer for 24 h to obtain flake precursor B.

[0030] 3) Put product B in a tube furnace, the protective atmosphere is argon, the flow rate of argon is 100 sccm, and after the temperature is raised to 300 °C at a rapid rate of 10 °C / min, the flow rate of argon is adjusted to 200 sccm, Incubate for 1 hour, then heat up to 500 °C at a slow rate of 5 °C / min, and keep it for 1 h. After the incubation is over, continue to ventilate with argon until it cools down to room temperature. The flow rate of argon is 300 sccm to obtain the final The product Co is doped with FeNCN / C.

Embodiment 2

[0032] A preparation method of Co-doped FeNCN / C includes the following steps:

[0033] 1) Add 2.0 g of analytically pure cyanamide, 1.0 g of ferric amine citrate, and 0.2 g of cobalt acetate tetrahydrate into 20 mL of deionized water and stir for 2 h to form an iron salt complex, labeled as solution A;

[0034] 2) Freeze solution A at -30°C for 2 h, and then dry it in a vacuum freeze dryer for 24 h to obtain flake precursor B.

[0035] 3) Put product B in a tube furnace, the protective atmosphere is argon, and the flow rate of argon is 100 sccm. After heating to 300 °C at a rapid rate of 12°C / min, adjust the flow rate of argon to 200 sccm. Incubate for 1 hour, then increase the temperature to 450 °C at a slow rate of 3°C / min, and keep it for 2 hours to obtain the final product Co-doped FeNCN / C.

[0036] The above Example 1 is the best example, and the product obtained in Example 1 is analyzed:

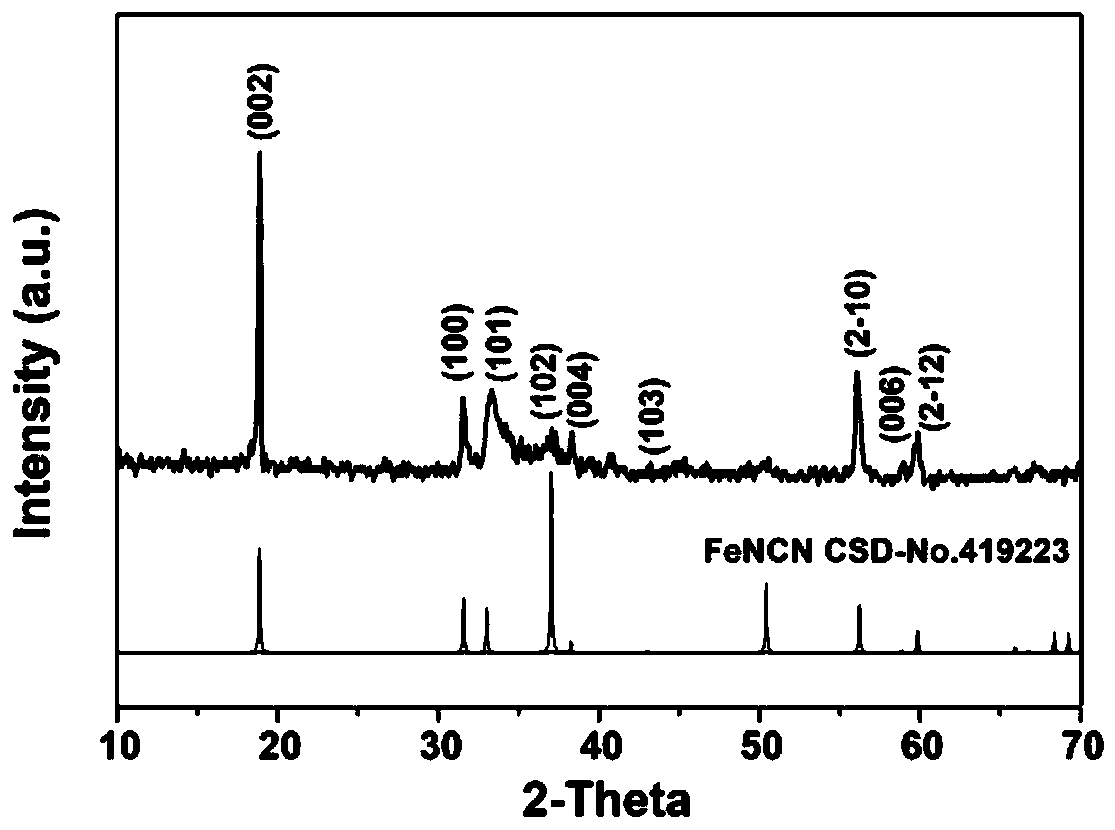

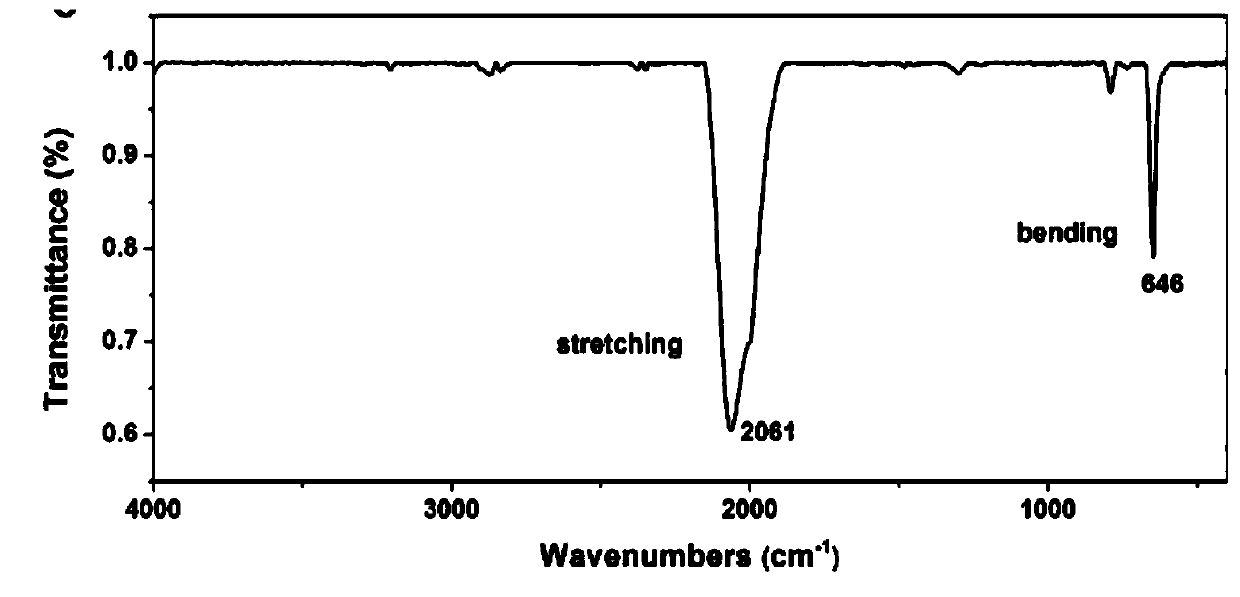

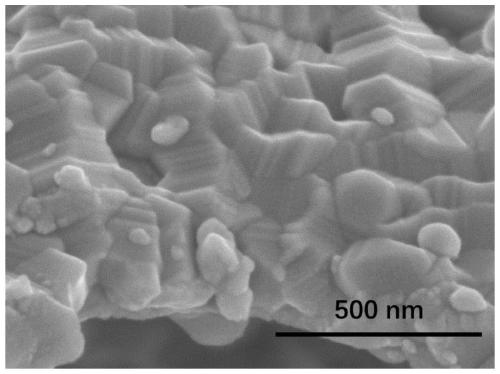

[0037] Through XRD characterization and analysis, the XRD pattern and FTIR pattern of the C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com