High-performance positive electrode material, preparation method thereof, and application of positive electrode material in lithium ion battery

A technology of positive electrode materials and positive active materials, applied in the field of high-performance positive electrode materials and their preparation, can solve problems such as lattice interface damage, achieve improved ionic conductivity, improved electronic conductivity and rate performance, and high electrochemical performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

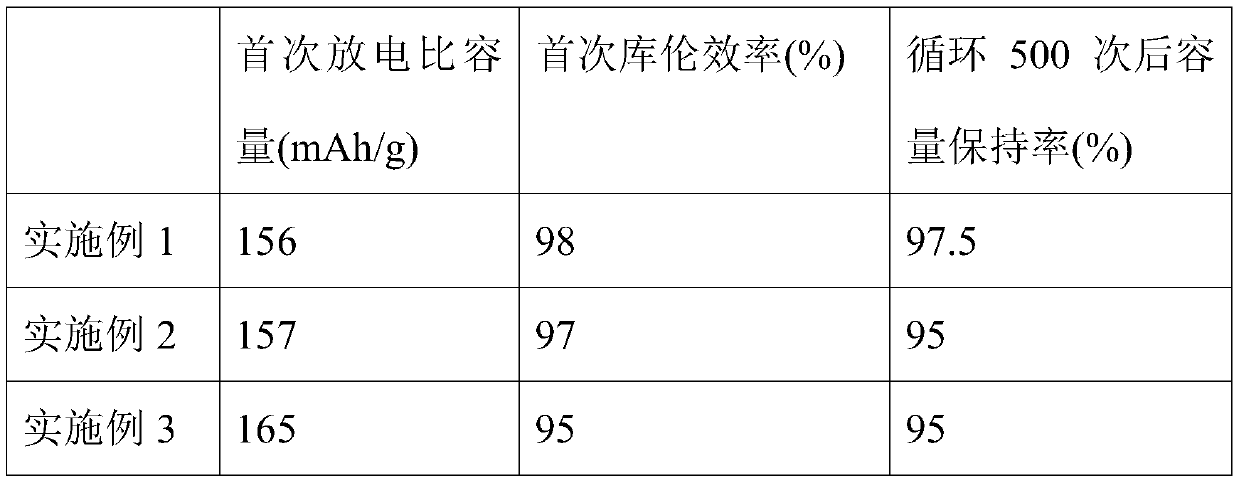

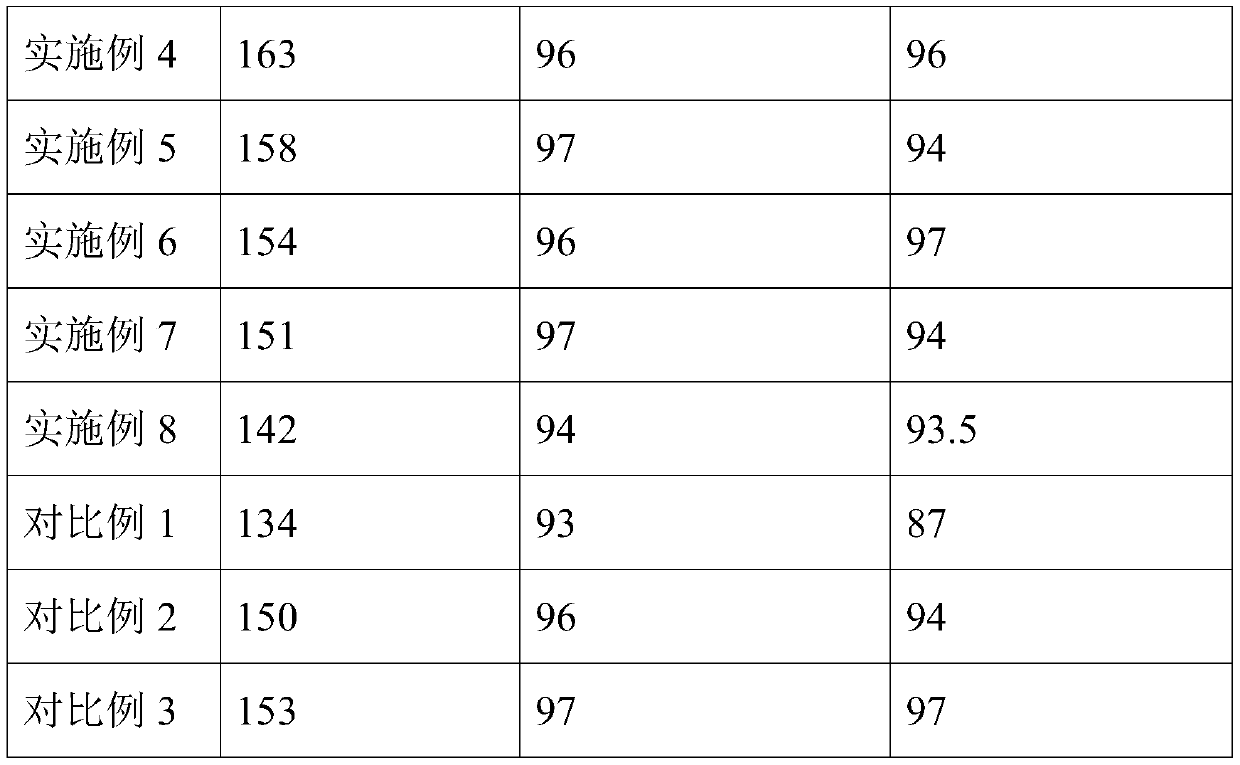

Examples

Embodiment 1

[0080] In the positive electrode material described in this embodiment, based on the mass of the positive electrode material as 100%, the mass percentage of the first coating is 10%, and the mass percentage of the second coating is 0.05%;

[0081] In the first cladding, conductive polymer / graphene / carbon nanotube composite, hydrogen-containing lithium titanium oxide compound and FeF 3 (H 2 O) 0.33 The mass ratio of the conductive polymer, graphene and carbon nanotubes in the conductive polymer / graphene / carbon nanotube composite is 1:1.5:6.5;

[0082] The preparation method of described cathode material comprises the following steps:

[0083] (1) dissolving starch in isopropanol to obtain solution A;

[0084] (2) Add the first coating to the solution A obtained in step (1), stir well to obtain solution B;

[0085] (3) Ferric phosphate is added to solution B obtained in step (2), and sand-milled to a particle size of 250 nm to obtain slurry C;

[0086] (4) Spray-dry the slu...

Embodiment 2

[0091] In the positive electrode material described in this embodiment, based on the mass of the positive electrode material as 100%, the mass percentage of the first coating is 0.5%, and the mass percentage of the second coating is 10%;

[0092] In the first cladding, conductive polymer / graphene / carbon nanotube composite, hydrogen-containing lithium titanium oxide compound and FeF 3 (H 2 O) 0.33 The mass ratio is 7:2.5:0.5; the mass ratio of conductive polymer, graphene and carbon nanotubes in the conductive polymer / graphene / carbon nanotube composite is 0.2:3:8;

[0093] The preparation method of described cathode material comprises the following steps:

[0094] (1) Gum Arabic is dissolved in tetrahydrofuran to obtain solution A;

[0095] (2) Add the first coating to the solution A obtained in step (1), stir well to obtain solution B;

[0096] (3) Add ferromanganese phosphate into solution B obtained in step (2), and sand-mill until the particle size is 600nm to obtain sl...

Embodiment 3

[0102] In the positive electrode material described in this embodiment, based on the mass of the positive electrode material as 100%, the mass percentage of the first coating is 15%, and the mass percentage of the second coating is 0.1%;

[0103] In the first cladding, conductive polymer / graphene / carbon nanotube composite, hydrogen-containing lithium titanium oxide compound and FeF 3 (H 2 O) 0.33 The mass ratio is 9.4:0.5:0.1; the mass ratio of conductive polymer, graphene and carbon nanotube in the conductive polymer / graphene / carbon nanotube composite is 2:0.1:9.8;

[0104] The preparation method of described cathode material comprises the following steps:

[0105] (1) Dissolving hydroxyethyl cellulose in ethylene glycol to obtain solution A;

[0106] (2) Add the first coating to the solution A obtained in step (1), stir well to obtain solution B;

[0107] (3) adding vanadium phosphate to solution B obtained in step (2), and sanding until the particle size is 1000nm to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com