Gastrointestinal surgical operation suture line and manufacturing method thereof

A surgical suture and surgical technique, applied in the field of medical devices, to achieve the effect of increased flexibility and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

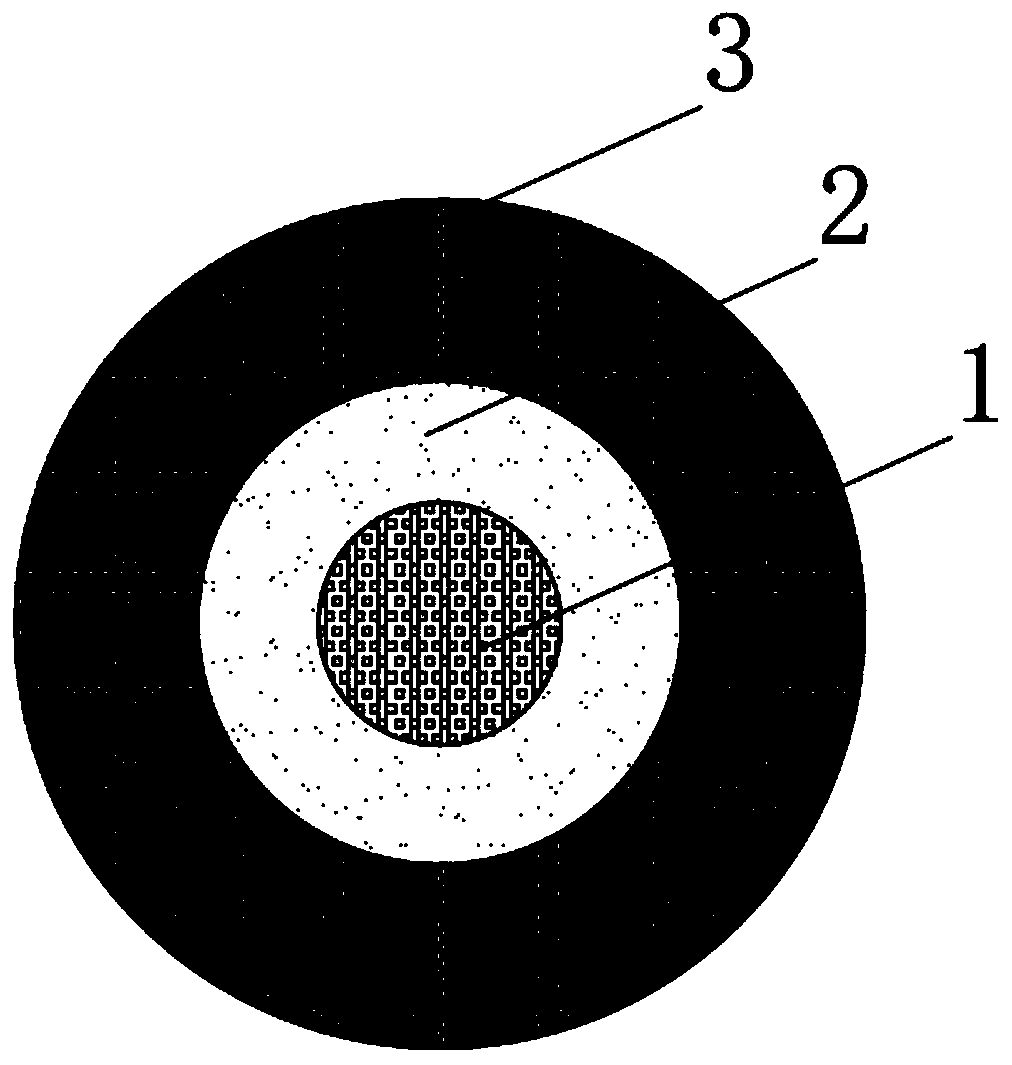

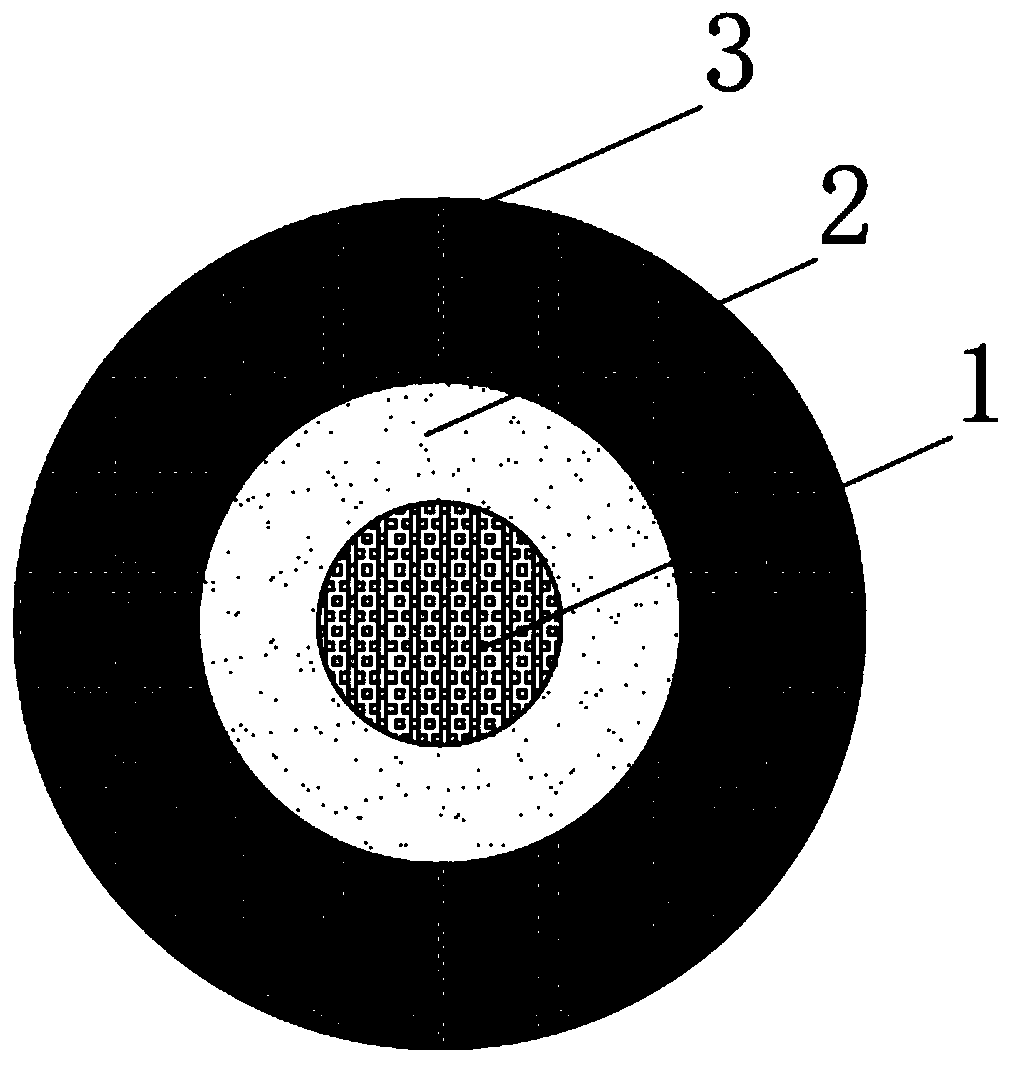

[0019] A surgical suture for gastrointestinal surgery, the surgical suture is composed of three layers, the innermost layer is an alloy core material 1, the second layer outward is a biopolymer layer 2, and the third layer is a collagen layer 3 , the thickness ratio of the biopolymer layer 2 to the collagen layer 3 is 1:2, the alloy core material 1 is linear, and its diameter is 40 microns, and the sheep intestine layer and the collagen layer 3 are all wound on the alloy core The surface of material 1. The alloy core material 1 is made of zinc-magnesium alloy. The biopolymer layer 2 is prepared by degreasing animal casings. The collagen layer 3 is made of the striated tendon of the beaver's spine.

[0020] A method for making surgical sutures for gastrointestinal surgery, comprising the following steps:

[0021] S1): Preparation of alloy core material 1: 5g of magnesium oxide, 1g of soybean lecithin and 2g of citric acid are added to a reaction vessel storing 20wt% KOH solu...

Embodiment 2

[0027] A surgical suture for gastrointestinal surgery, the surgical suture is composed of three layers, the innermost layer is an alloy core material 1, the second layer outward is a biopolymer layer 2, and the third layer is a collagen layer 3 , the thickness ratio of the biopolymer layer 2 and the collagen layer 3 is 1.1:2.2, the alloy core material 1 is linear, and its diameter is 50 microns, and the sheep intestine layer and the collagen layer 3 are all wound on the alloy core The surface of material 1. The alloy core material 1 is made of zinc-magnesium alloy. The biopolymer layer 2 is prepared by degreasing animal casings. The collagen layer 3 is made of the striated tendon of the beaver's spine.

[0028] A method for making surgical sutures for gastrointestinal surgery, comprising the following steps:

[0029]S1): Preparation of alloy core material 1: Add 6g of magnesium oxide, 2g of soybean lecithin and 3g of citric acid into a reaction vessel storing a 20wt% KOH so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com