Industrial waste liquid regenerant and preparation method thereof

A regenerant and aqueous solution technology, which is applied in the field of water-soluble polymer regenerant and its preparation, can solve the problems of high iron recovery rate, secondary pollution, and large power consumption, so as to improve quality, reduce enterprise costs, and improve environmental benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

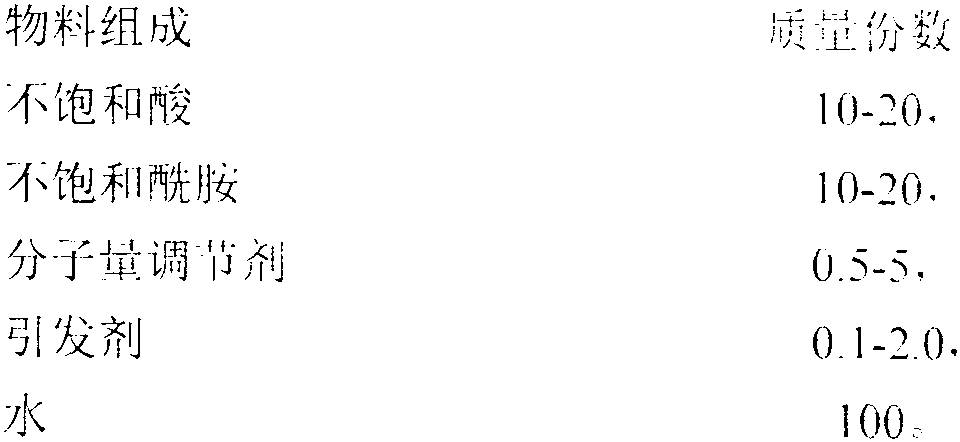

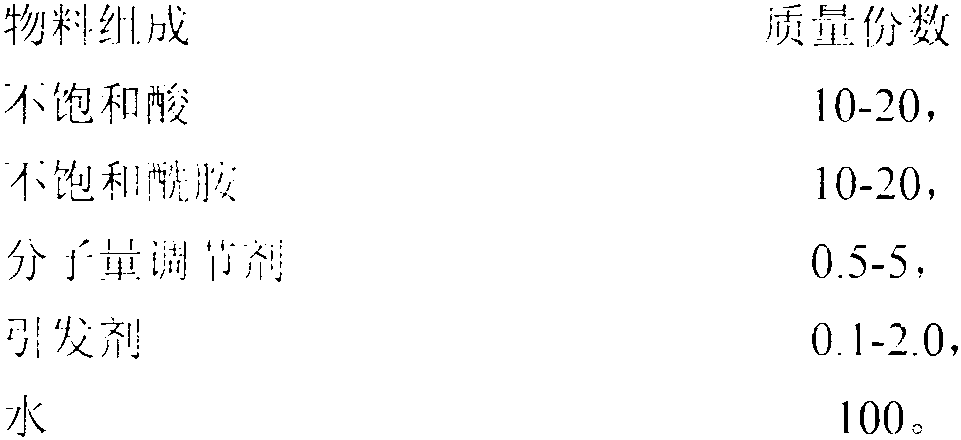

Method used

Image

Examples

Embodiment 1

[0031] The parts by mass are calculated in grams. 15 grams of acrylic acid is used as an unsaturated acid material, 7.5 grams of acrylamide is used as an unsaturated amide material, and 0.5 grams of thioglycolic acid is used as a molecular weight modifier material, and they are mixed in proportion to prepare a raw material mixture for later use. Add 100 grams of distilled water to the reactor equipped with stirrer, thermometer, dropping funnel and nitrogen conduit, start stirring, replace with argon for 15 minutes, when the water bath is heated to 80 ° C, add 3 grams of 10% super Aqueous solution of ammonium sulfate. After 10 minutes, the above-mentioned raw material mixture was continuously added dropwise with a dropping funnel, and the dropping speed was controlled, and the dropping was completed within 2.5 hours. The temperature of the system was raised to 85°C and kept for 1.5 hours. Under the action of stirring, the system is lowered to room temperature, and the material...

Embodiment 2

[0034] The parts by mass are expressed in grams, and an aqueous solution is prepared with 12 grams of acrylic acid as the unsaturated acid material and 20 grams of water, and cooled to room temperature. 5 grams of acrylamide and 2.5 grams of N,N-dimethylacrylamide are used as the unsaturated amide material, and 1.3 grams of mercaptopropionic acid is used as the molecular weight regulator material, which is mixed with the unsaturated acid material to form a raw material mixture, which is set aside. Add 80 grams of distilled water to the reactor equipped with stirrer, thermometer, dropping funnel and nitrogen conduit, start stirring, replace with nitrogen for 20 minutes, when the water bath is heated to 80°C, add 6 grams of persulfuric acid with a mass concentration of 3%. Potassium aqueous solution. After 10 minutes, the above-mentioned raw material mixture was continuously added dropwise with a dropping funnel, and the dropping speed was controlled, and the dropping was comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com