Powder synthesis furnace and method based on low-temperature self-propagating combustion principle

A technology of self-propagating combustion and synthesis furnace, which is applied in the fields of nanotechnology, furnace and electric furnace heating for materials and surface science, and can solve the problems of difficult control of self-propagating combustion reaction, slow technological development, low enthusiasm, etc. The effect of powder production cost, simplifying production process and reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

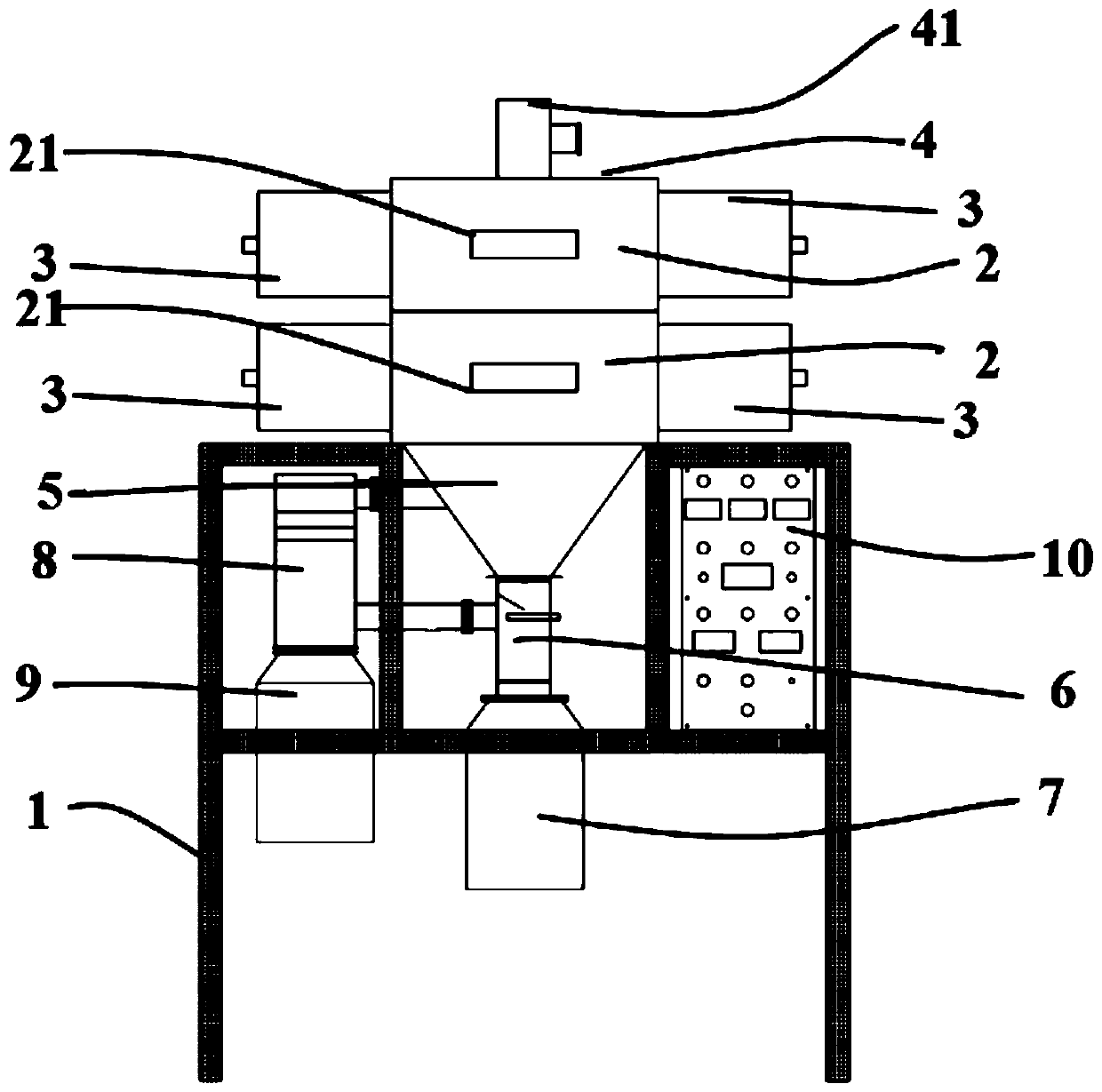

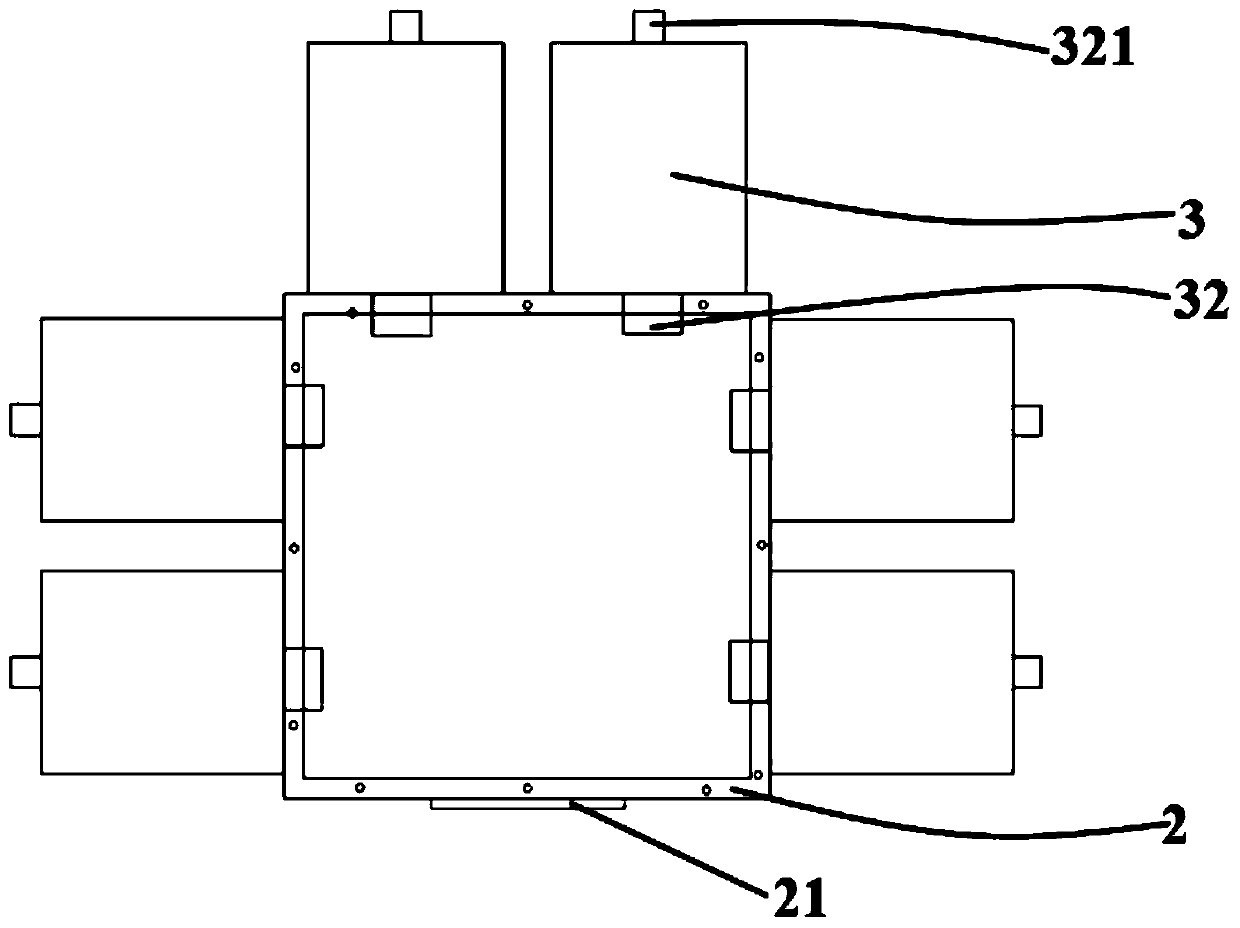

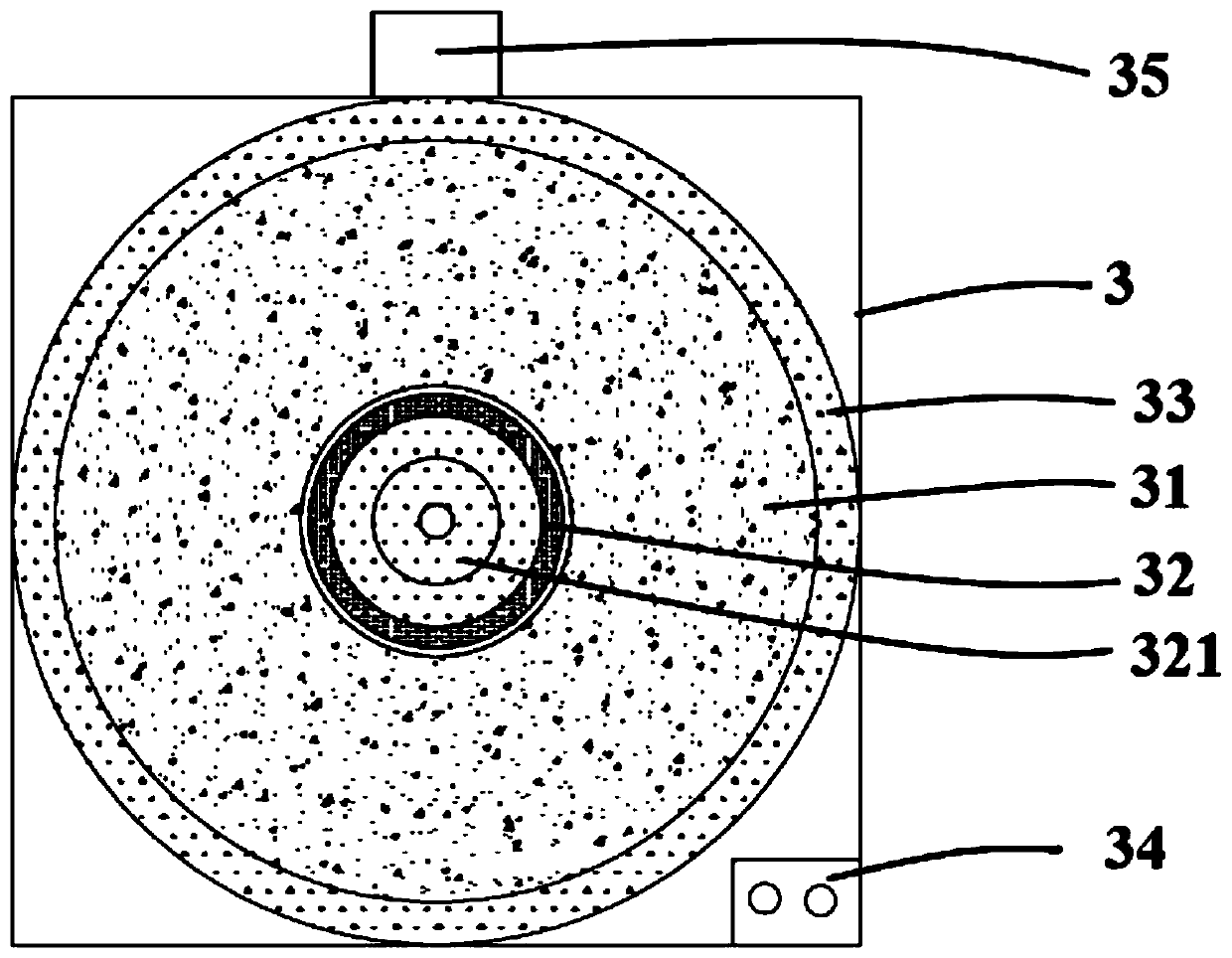

[0040] The present invention will be described in further detail below with reference to the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

[0041] The inventor believes that continuous and stable supply of reaction materials is a prerequisite for realizing controllable self-propagating combustion, and is the key to determine whether the low-temperature self-propagating combustion synthesis method can be applied to continuous production. After a large number of experimental studies, the inventors have proved that the reaction materials capable of initiating self-propagating combustion are not limited to xerogels, and the concentrated aqueous solutions of metal nitrates and organic substances such as citric acid, glycine, glucose, urea, and polyethylene glycol can also undergo continuous combustion. , Stable self-propagating combustion. If concentrated solution is used as the reactant, corrosion-resistant pumps ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com