Preparation method of carbon-sulfur composite positive electrode material added with auxiliary agent

A carbon-sulfur composite, cathode material technology, applied in the direction of positive electrode, battery electrode, active material electrode, etc., can solve the problems of cycle stability deterioration, limited adsorption, battery capacity attenuation, etc., to enhance cycle stability and life, Improve utilization and reduce the effect of polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Mix porous carbon (CMK) and sublimated sulfur powder according to the mass ratio of 2:3 and grind until uniform; then heat the mixture to 155°C under the protection of argon in the ampoule bottle, and keep the constant temperature for 6 hours; wait for natural cooling After reaching room temperature, the gray-black powder is taken out, which is the CMK sulfur-supported composite material (CMK / S).

[0023] (2) The prepared CMK / S, graphene (N-methylpyrrolidone dispersion), PVDF and auxiliary agent dithiothreitol (DTT) are mixed in N-methyl Pyrrolidone was thoroughly mixed and stirred until uniform to obtain a slurry.

[0024] (3) The obtained slurry was coated on the surface of aluminum foil, vacuum-dried at 30° C. for 8 hours, and then cut to obtain a positive electrode sheet; further, sodium was used as a negative electrode to assemble a button battery.

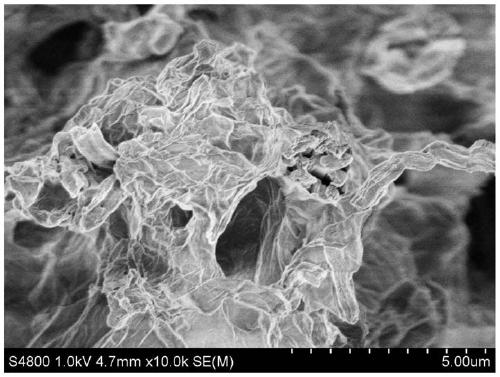

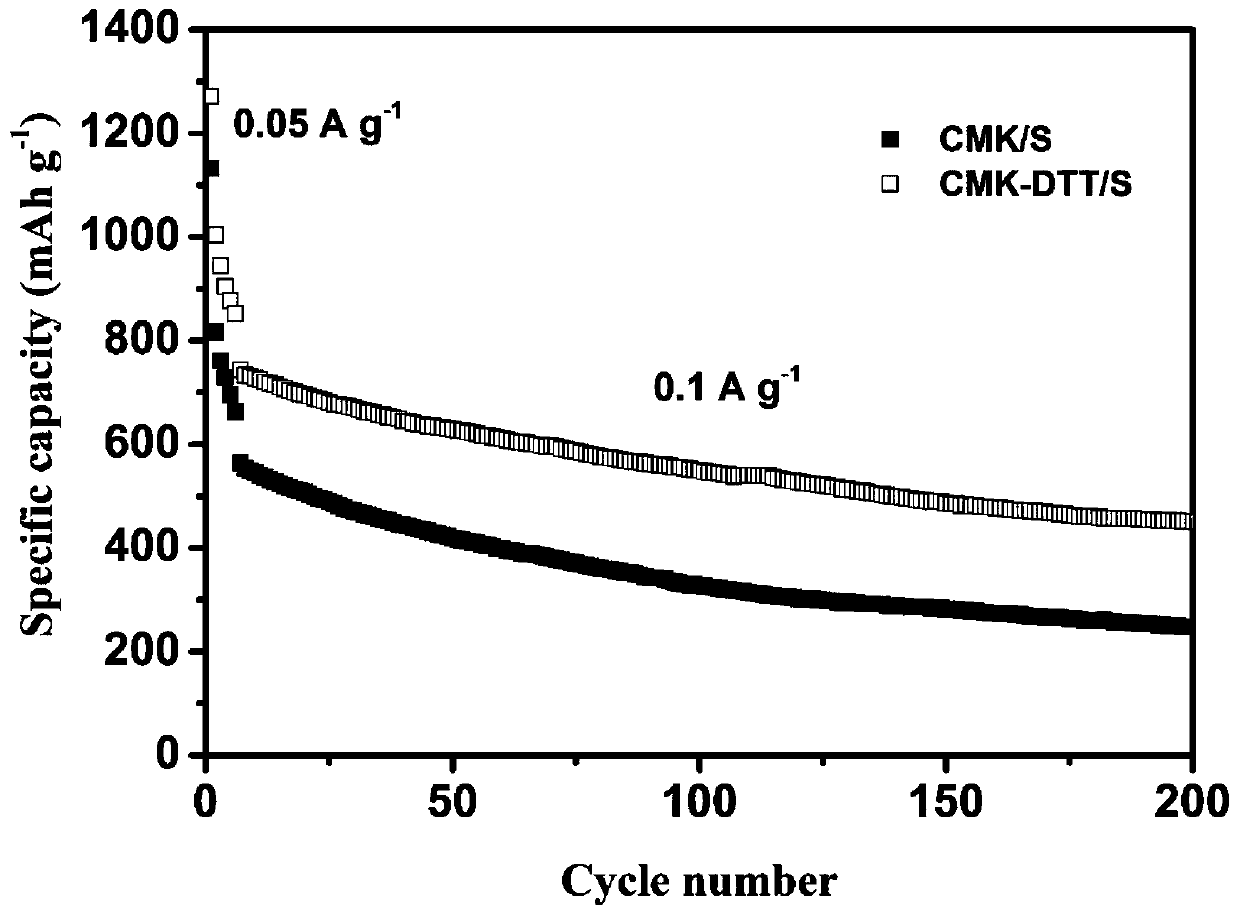

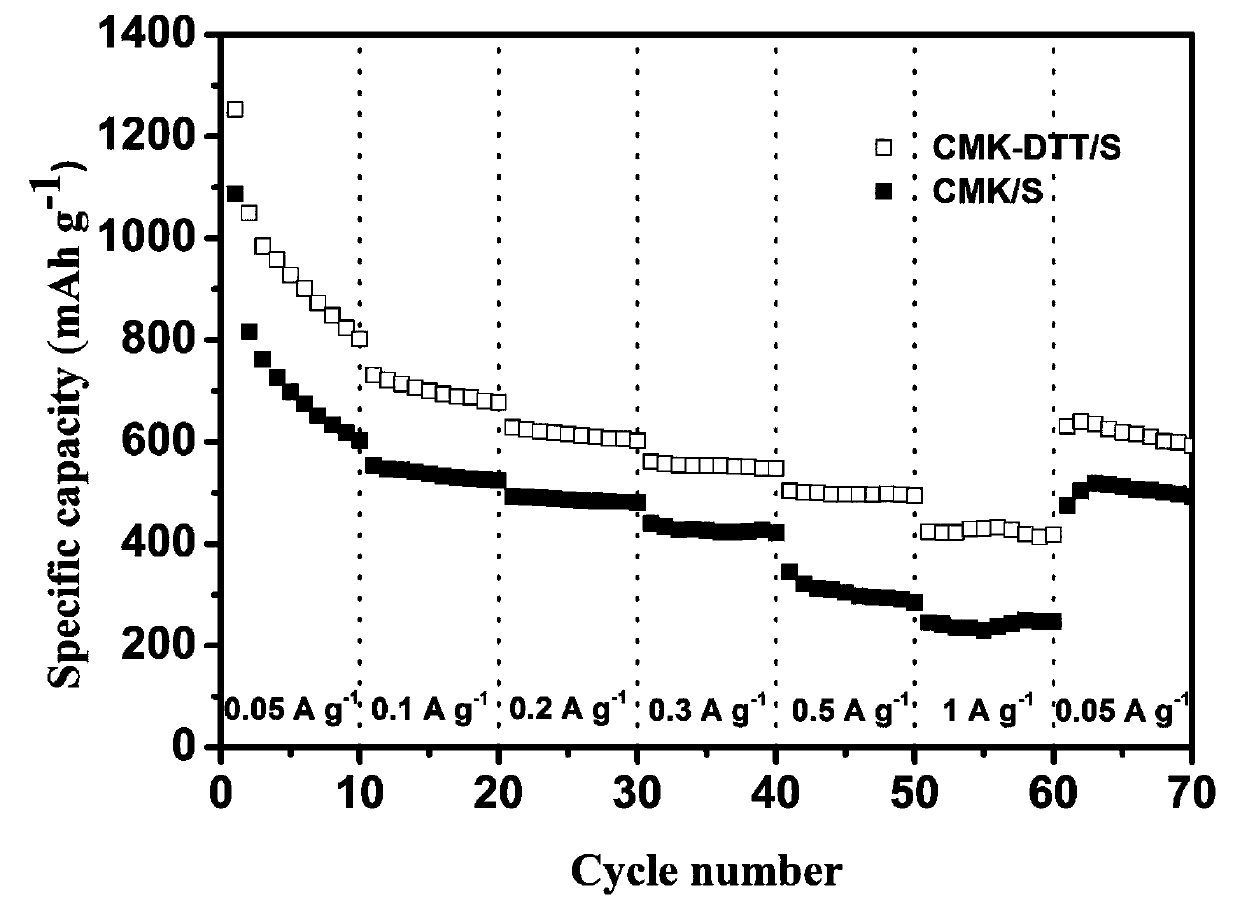

[0025] The morphology of the as-prepared cathode material is shown in the attached figure 1 shown. The carbo...

Embodiment 2

[0027] (1) Mix carbon nanotubes and sublimed sulfur powder according to the mass ratio of 2:3 and grind them until they are uniform; then heat the mixture to 155°C under the protection of argon in the ampoule bottle, and keep the temperature for 6 hours; wait for natural cooling to room temperature Finally, take out the gray-black powder, which is the composite material of carbon nanotubes loaded with sulfur.

[0028] (2) The prepared carbon nanotube-loaded sulfur composite material, Ketjen black, PVDF and additive glutathione are fully mixed and stirred in N-methylpyrrolidone according to the mass ratio of 7:1:1:1 until uniform , to obtain a slurry.

[0029] (3) The obtained slurry was coated on the surface of aluminum foil, vacuum-dried at 60° C. for 5 hours, and then cut to obtain a positive electrode sheet; further, sodium was used as a negative electrode to assemble a button battery.

Embodiment 3

[0031] (1) Mix porous carbon (CMK) and sublimated sulfur powder according to the mass ratio of 2:3 and grind until uniform; then heat the mixture to 155°C under the protection of argon in the ampoule bottle, and keep the constant temperature for 6 hours; wait for natural cooling After reaching room temperature, the gray-black powder is taken out, which is the CMK sulfur-supported composite material (CMK / S).

[0032] (2) The prepared CMK / S, graphene (N-methylpyrrolidone dispersion), PVDF and auxiliary vitamin C are fully mixed and stirred in N-methylpyrrolidone according to the mass ratio of 7:1:1:1 until uniform.

[0033] (3) The obtained slurry was coated on the surface of aluminum foil, vacuum-dried at 60° C. for 5 hours, and then cut to obtain a positive electrode sheet; further, sodium was used as a negative electrode to assemble a button battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com