Preparation of high-hydrophobicity hollow fiber membrane and desulfurization wastewater treatment method thereof

A desulfurization wastewater, fiber membrane technology, applied in water/sewage treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

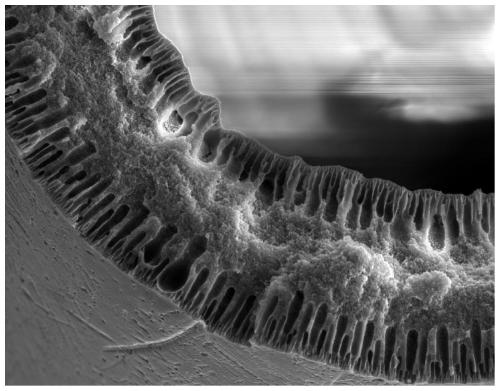

[0022] Preparation of hollow fiber membranes.

[0023] Using N-methylpyrrolidone (NMP) or dimethylacetamide (DMAC) as solvents, prepared nano-TiO containing 20wt% PVDF, 5wt% porogen, 1.5wt% hydrophobically modified 2 The casting solution of the sol, and vacuum defoaming of the prepared solution. A metering pump is used to extrude the casting solution from the hollow fiber membrane spinning head at a certain linear speed. The primary membrane enters the external flocculation tank after going through an air bath stroke with a length of 5-10 cm, and then passes through the retracting device at a certain line speed. Speed curl. The ratio of the extrusion speed of the casting solution to the stretching speed of the nascent film is between 2:30 and 2:50.

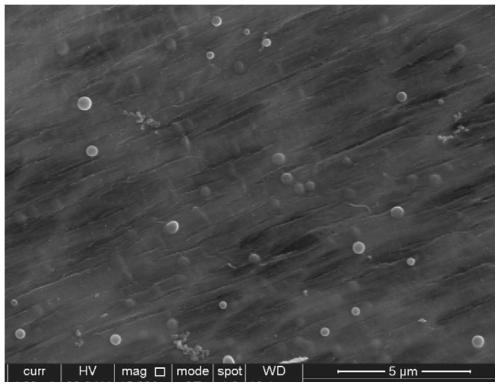

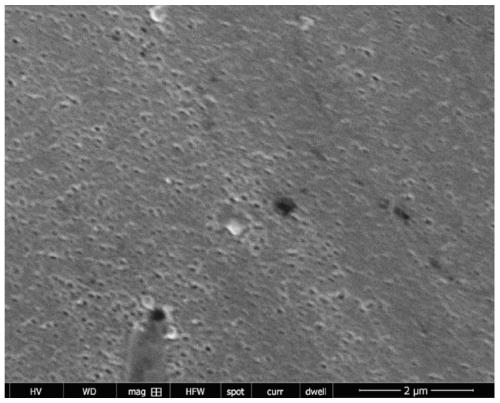

[0024] Characterization of hollow fiber membranes.

[0025] Soak the prepared hollow fiber membrane in tap water at room temperature for two days, and then obtain a highly hydrophobic hollow fiber membrane after solvent excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com