Preparation and application of SnO2 nanorod array/reduced graphene oxide composite nanomaterial sensitive to formaldehyde gas

A nanorod array and graphene composite technology, applied in the field of gas sensing, can solve the problems of complex experimental process, lack of electrical conductivity, flexibility and chemical stability, and achieve strong chemical sensitivity, high sensitivity, and large specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A kind of SnO 2 The preparation method of nanorod array / reduced graphene oxide composite nanomaterial, the raw material used in the preparation method of this material of the present invention comprises: Na 2 SnO 3 4H 2 O, absolute ethanol and water.

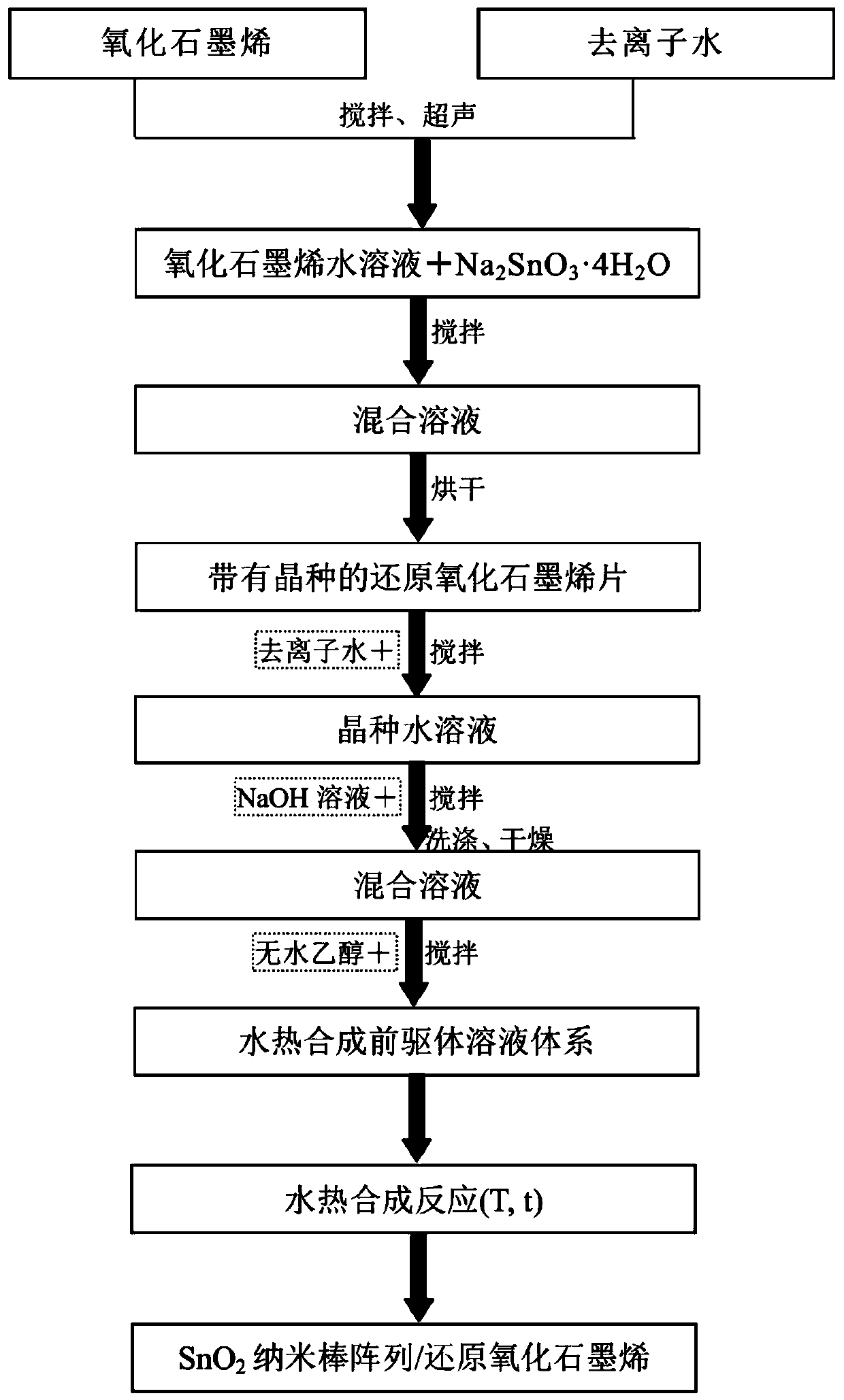

[0044] Further, the steps of the preparation method of the present invention are:

[0045] (1) Formation of seed crystals on the reduced graphene oxide substrate

[0046] a. Disperse a small amount of graphene oxide in a certain volume of deionized water, stir on a magnetic stirrer for 30 to 60 minutes, and then ultrasonicate at a certain working frequency for 3 to 6 hours;

[0047] b. Take Na 2 SnO 3 4H 2 O is the source of tin (irreplaceable), and a certain amount of Na is weighed with a balance 2 SnO 3 4H 2 O is dissolved in the above aqueous solution of graphene oxide, stirred for 8-12 hours, and dried at 80-100° C. to form crystal seeds;

[0048] (2) Preparation of precursor reaction solution for hydrother...

Embodiment

[0066] 1. SnO 2 Preparation of Nanorod Array / Reduced Graphene Oxide Composite Nanomaterials

[0067] The preparation process is as described in the summary of the invention, and the preparation process is as follows figure 1 shown.

[0068] Table 1, table 2 have listed preparation SnO in the present invention 2 Twenty implementation examples of nanorod array / reduced graphene oxide composite nanomaterials.

[0069] Table 1 Preparation of SnO 2 Ten implementation examples of various ratios of nanorod array / reduced graphene oxide composite nanomaterials (seed crystal drying temperature 80°C)

[0070]

[0071] Table 2 Preparation of SnO 2 Ten implementation examples of various ratios of nanorod array / reduced graphene oxide composite nanomaterials (seed crystal drying temperature 100°C)

[0072]

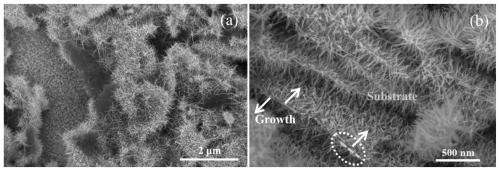

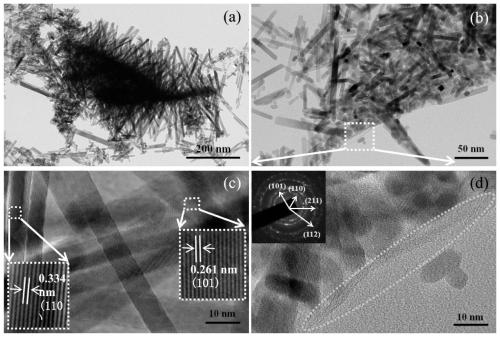

[0073] 2. SnO2 Examples of Sensing Properties of Nanorod Array / Reduced Graphene Oxide Composite Nanomaterials

[0074] (1) SnO 2 Sensitivity of Nanorod Array / Reduced Graphen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com