Device and method for degrading macrolide antibiotics in pharmaceutical wastewater, and applications of method

A technology for macrolides and pharmaceutical wastewater, applied to chemical instruments and methods, water pollutants, natural water treatment, etc., to achieve the effects of increasing specific surface area, reducing wasted time, and accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

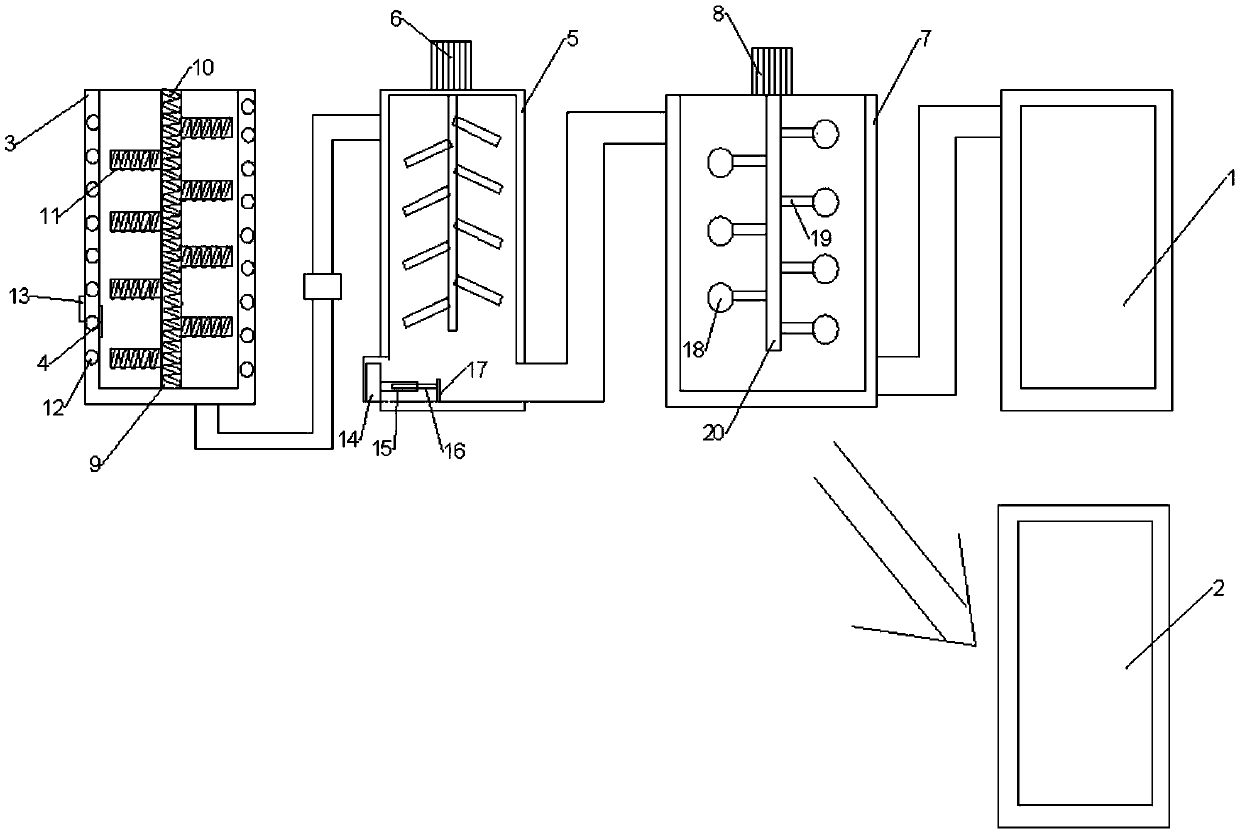

[0040] A device for degrading macrolide antibiotics in pharmaceutical wastewater, including a preheating tank, a reaction kettle, a solid-liquid separator, a liquid product storage tank 1 and a solid product drying device 2,

[0041] The preheating tank includes a preheating tank body 3, a side wall preheating device, a central preheating device and a temperature sensor 4. The side wall preheating device is arranged in the side wall of the preheating tank body 3, and one end of the central preheating device is installed on the The middle part of the bottom end of the preheating tank body 3, the other end of the central preheating device extends into the cavity of the preheating tank body 3, the temperature sensor 4 is fixed on the inner wall of the preheating tank body 3, through the side wall preheating device and the center The double function of the preheating device can improve the preheating efficiency of the reaction liquid, thereby reducing the time wasted on preheating;...

Embodiment 2

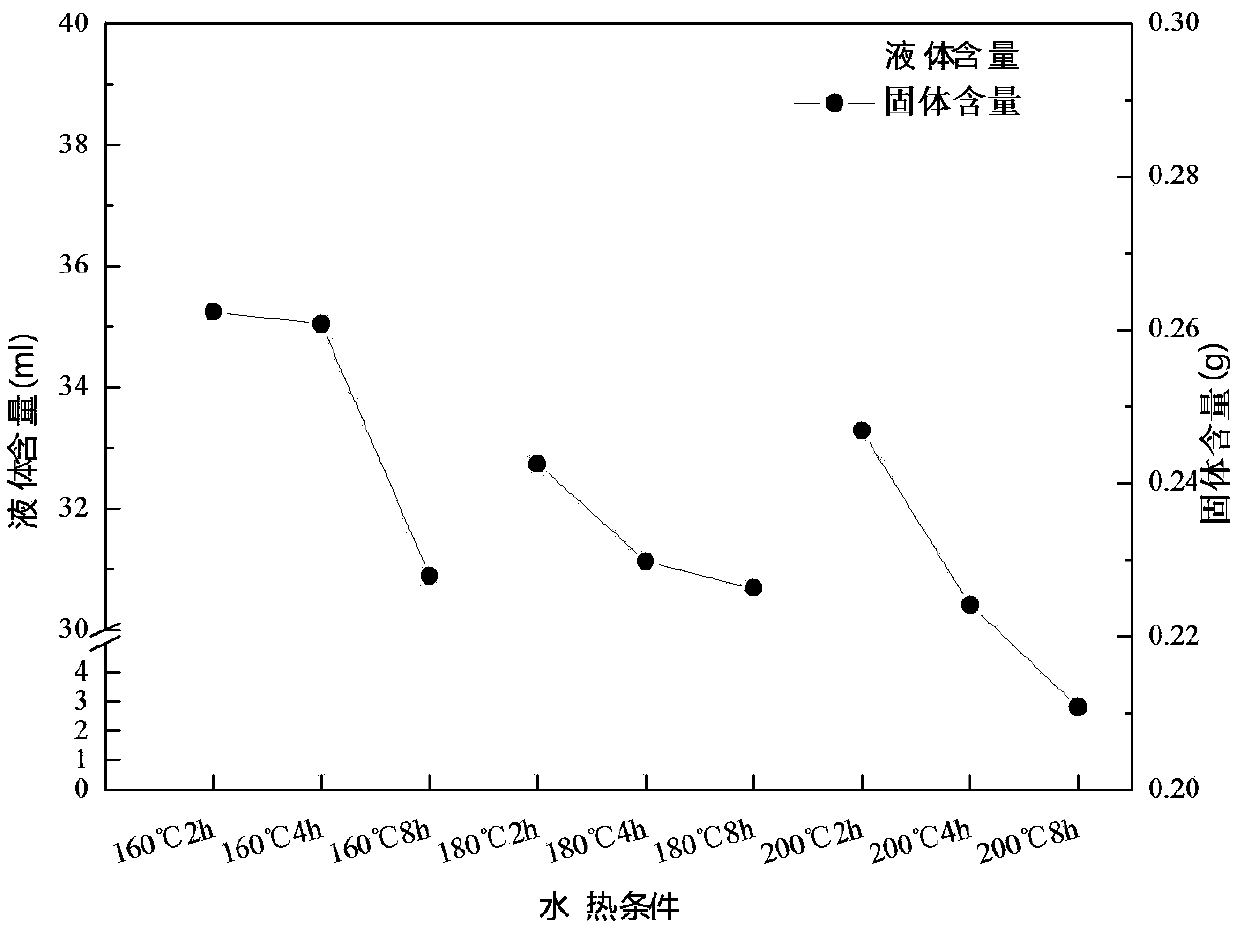

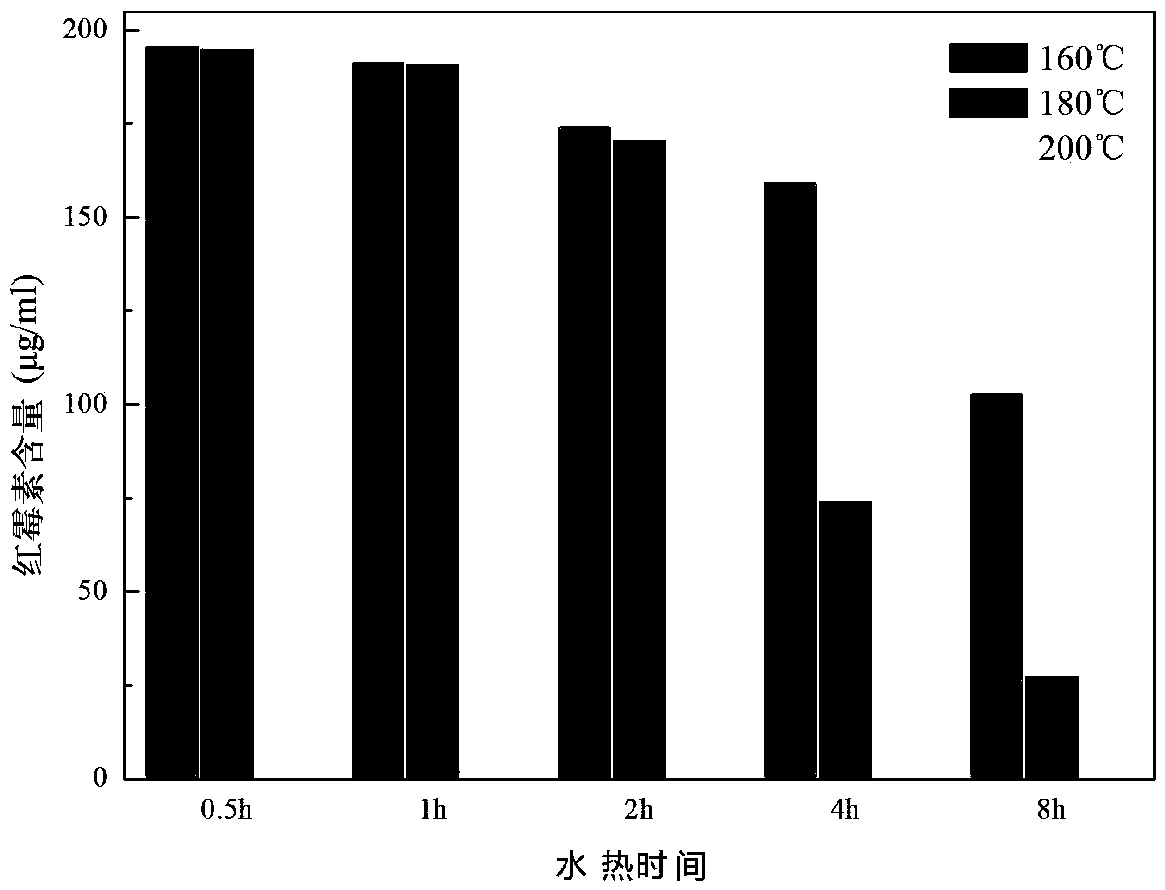

[0055] Add 40ml of antibiotic production wastewater into a 50ml reactor, seal it and put it in a blast drying oven, heat it at 160°C for 2h, 4h and 8h respectively, remove the reactor after the reaction is over and cool it to room temperature, take out the product and put it in a In a 50ml centrifuge tube, centrifuge at 8000rpm for 20min, save the solid-liquid product, and analyze the related properties of the solid-liquid product.

Embodiment 3

[0057] Add 35ml of antibiotic production wastewater into a 50ml reactor, seal it and put it in a blast drying oven, heat it at 180°C for 2h, 4h and 8h respectively, remove the reactor after the reaction is over and cool it to room temperature, take out the product and put it in a In a 50ml centrifuge tube, centrifuge at 6000rpm for 30min, save the solid-liquid product, and analyze the related properties of the solid-liquid product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com