Cement-based composite material and application thereof

A composite material and cement-based technology, which is applied in roads, pavement details, buildings, etc., can solve the problems of limited application range and poor toughness, and achieve the effect of simple and easy preparation method, excellent mechanical performance and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

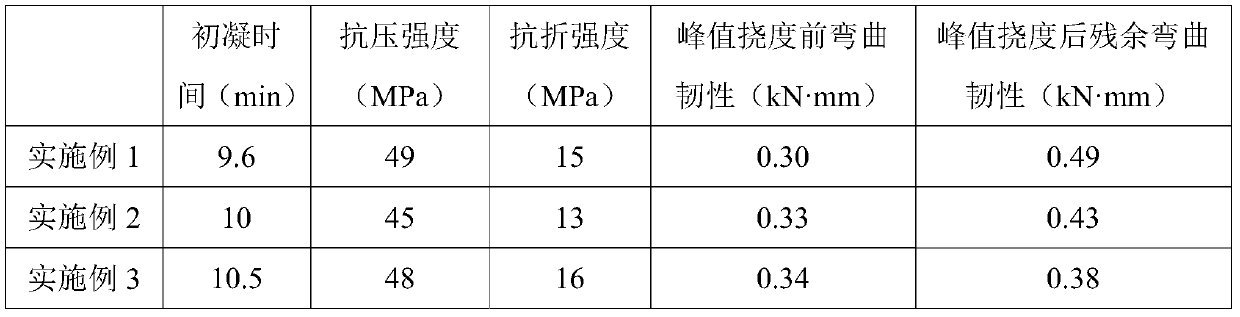

[0030] Embodiment: a kind of cement-based composite material, the raw material of specific embodiment and mass percent are as shown in table 1:

[0031] Raw material composition and mass percentage (%) thereof of table 1 embodiment 1-3

[0032] magnesium oxide Potassium dihydrogen phosphate fly ash Borax coconut fiber water Example 1 42.51 28.92 10.71 4.25 1.27 12.34 Example 2 42.51 28.92 10.71 4.68 0.85 12.33 Example 3 41.98 28.56 10.58 5.04 1.68 12.16

[0033] A method for preparing a building component, comprising the steps of:

[0034] (1) Take raw materials according to the composition of Table 1;

[0035] (2) Potassium dihydrogen phosphate, borax, and fly ash are mixed evenly, and dry mixed for 1 minute to form a uniform dry material mixture;

[0036] (3) Add water and stir for 3 minutes to form a uniform slurry;

[0037] (4) Add magnesium oxide, stir at a low speed for 30 seconds, and then stir at a high speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com