Potato starch production line and production method thereof

A potato starch and production line technology, applied in food science, food processing, application, etc., can solve problems such as low starch purity, complex production process, and incomplete cleaning, and achieve high product purity, simple process flow, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

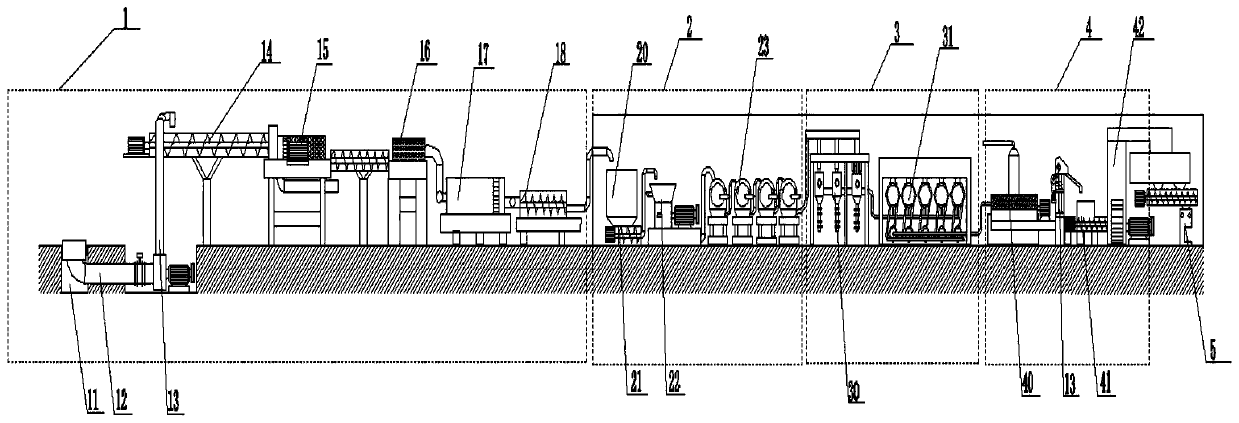

[0020] Such as figure 1 figure 2 As shown, a potato starch production line includes a cleaning and stone removal system 1, a crushing and screening system 2, a filtration extraction system 3, a drying system 4 and a packaging system 5, and the cleaning and stone removal system 1 passes through the pipeline and the crushing and screening system 2, the other end of the crushing and screening system 2 is connected to one end of the filtration extraction system 3 through a pipeline, the other end of the filtration extraction system 3 is connected to one end of the drying system 4 through a pipeline, and the other end of the drying system 4 is passed through The pipes are connected to the packaging system 5 .

[0021] Cleaning and stone removal system 1 includes two cleaning tanks 11 arranged in series, negative pressure conveying pipeline 12, hoist 13, screw conveying pipeline 14, stone remover 15, drum drainage machine 16 and water washing device, and two cleaning channels arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com