Preparation method of white carbon black/natural rubber composite material

A technology of natural rubber and composite materials, which is applied in the field of continuous preparation of white carbon black/natural rubber composite materials. It can solve problems affecting the health of operators, the performance of rubber products, and the performance of rubber products, and achieve physical properties and dynamic mechanics. The effect of performance improvement, continuous processing method, and reduction of mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

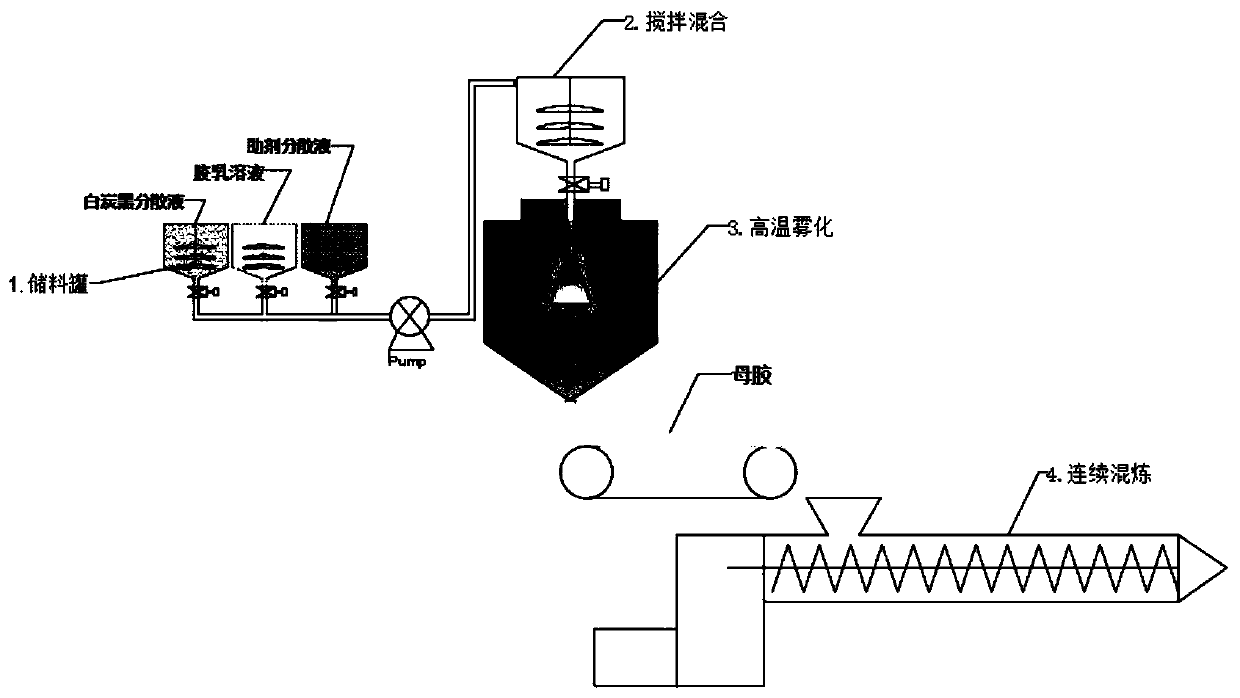

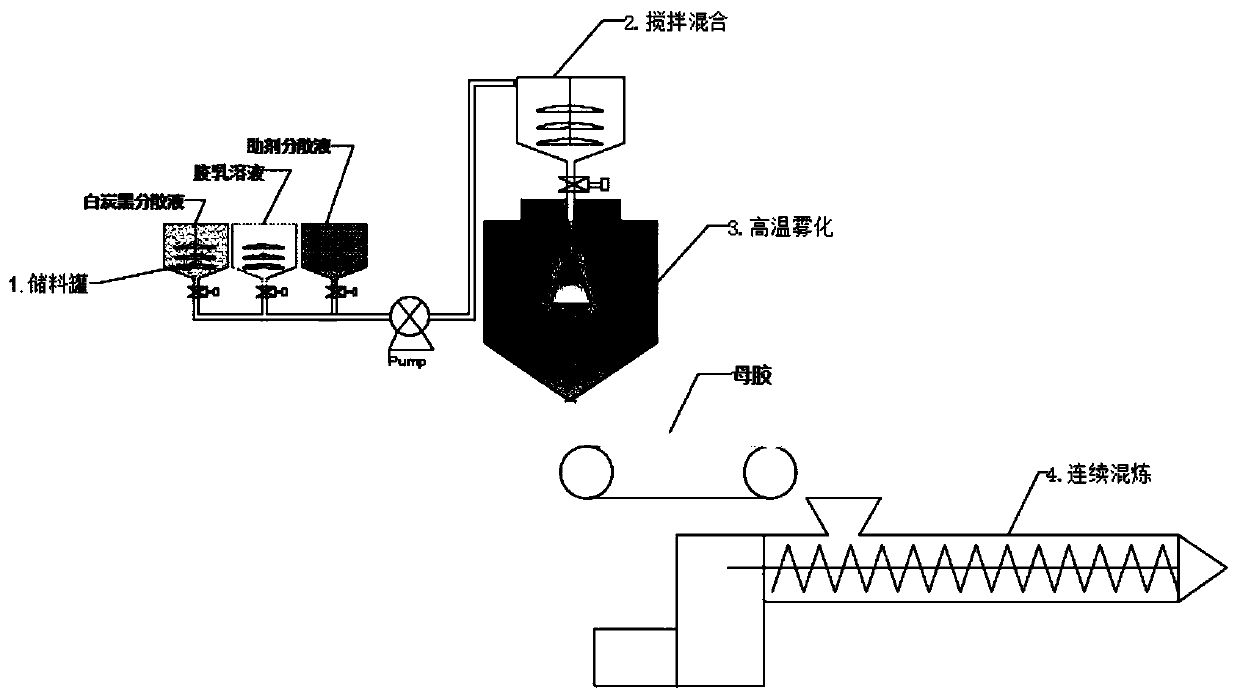

[0015] The preparation method of the silica / natural rubber composite material involved in this embodiment is a high-temperature atomization method, and the process includes four steps of preparing an aqueous solution of silica, preparing an aqueous solution of auxiliary agents, preparing a silica masterbatch, and continuous mixing:

[0016] (1) Preparation of white carbon black aqueous solution: add 40 parts by mass of SiO in No. 1 beaker 2 (silicon dioxide), 5 parts by mass of liquid Si69 (silane coupling agent) solution and deionized water are mixed with 25wt% white carbon black aqueous solution, and the white carbon black aqueous solution is placed in an ultrasonic oscillator with a frequency of 1000 Hz for ultrasonic 10min, Then the solution after the ultrasonic wave is placed in a planetary ball mill for secondary crushing and grinding for 4 hours;

[0017] (2) Preparation of auxiliary agent aqueous solution: add 20 parts by mass of SiO in No. 2 beaker 2 (silicon dioxide...

Embodiment 2

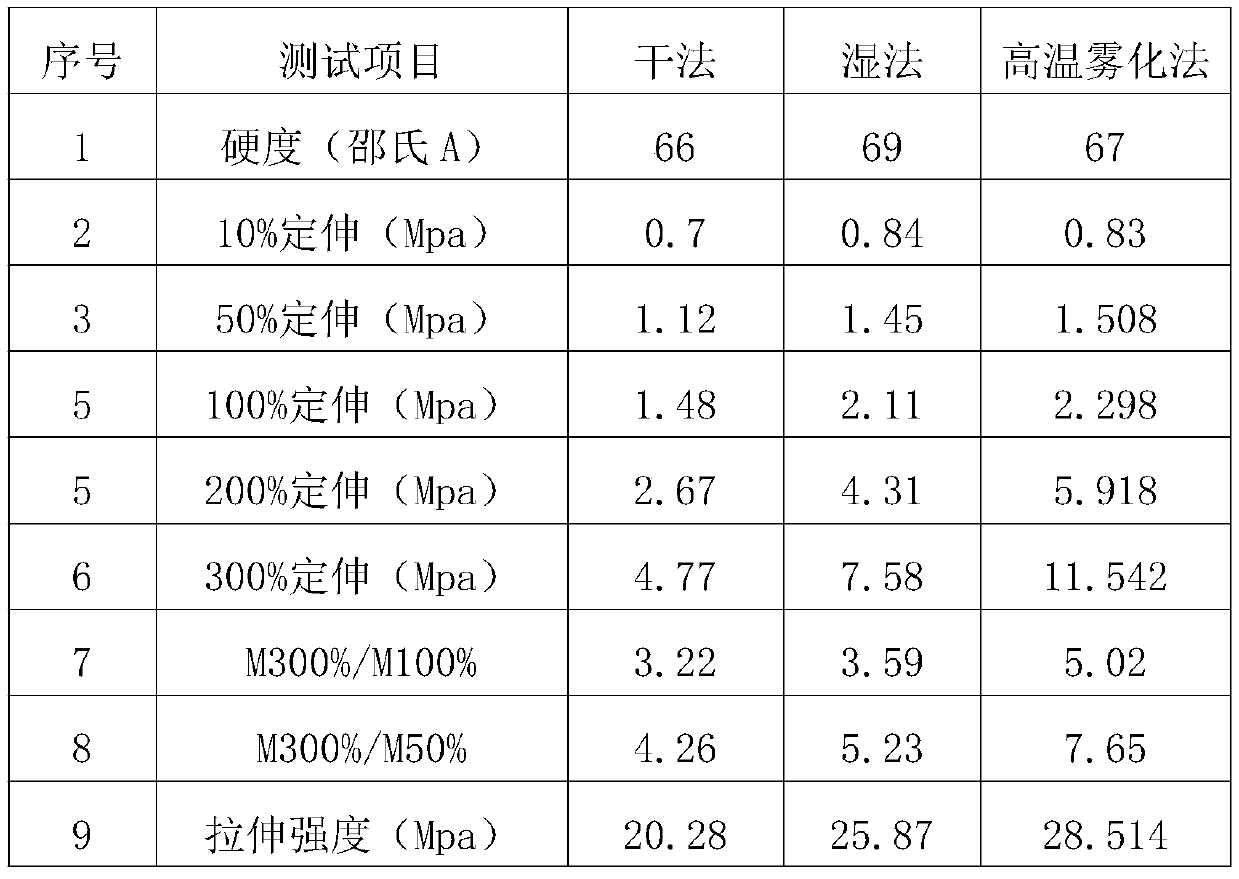

[0021] This example relates to the comprehensive performance test of the vulcanized compound of silica / natural rubber composite material. The silica / natural rubber composite material will be prepared by using smoked sheet glue-dry method, acid flocculation method-wet method and high-temperature atomization method respectively. Prepare into rubber compound, wherein, the preparation process of high temperature atomization method rubber compound is: the white carbon black / natural rubber composite material prepared in step (4) and 1 mass part S (sulfur) and 1.2 mass parts CZ (N-ring Hexyl-2-benzothiazole sulfenamide) is placed in the open mill and passed through 6 times to obtain the rubber compound; three parts of the rubber compound are carried out to the mechanical performance test respectively, and the results are as follows:

[0022]

[0023]

[0024] According to the data of tensile strength and tear strength, it can be seen that the rubber compound prepared by high tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com