Passive capacitance pen point, passive capacitance pen and pen point preparation method

A capacitive pen, passive technology, applied in electrical digital data processing, instruments, computing and other directions, can solve problems such as the decline of mechanical properties such as toughness and impact resistance, splitting the continuous phase of the matrix material, and destroying the integrity, so as to improve the writing smoothness. Slip, reduce components, reduce the effect of surface friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

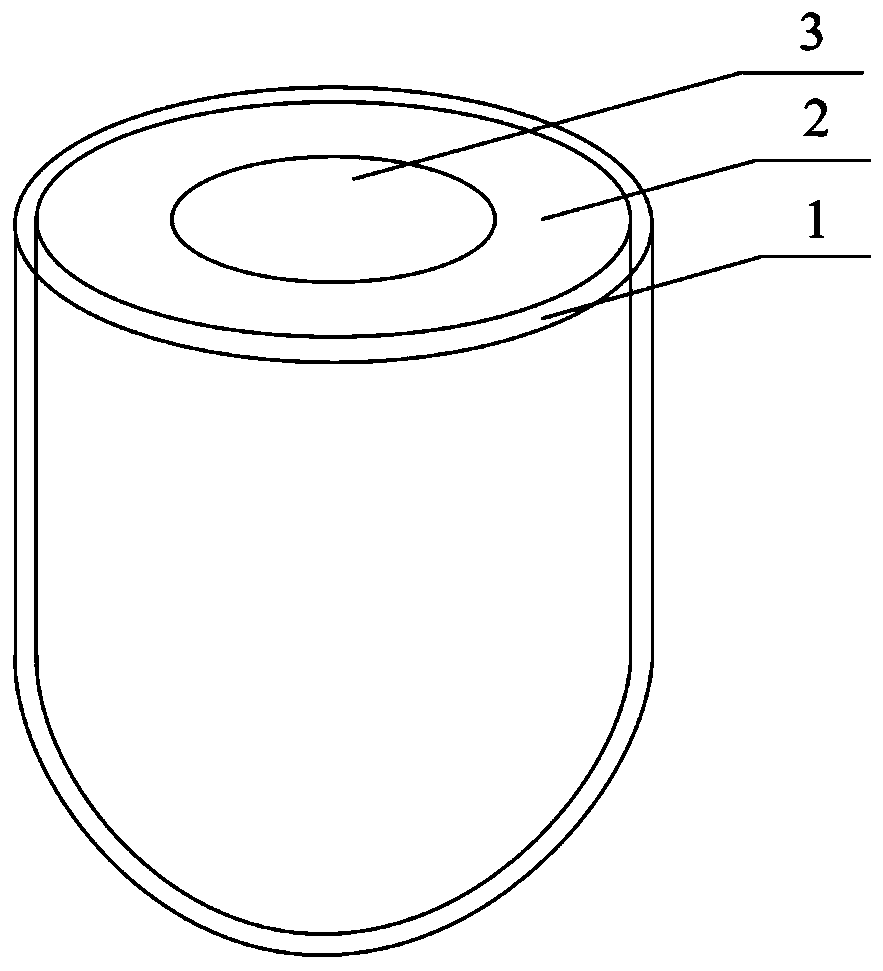

[0041] The passive capacitive pen nib of the present embodiment, as figure 1 As shown, it includes a nib outer layer 1 and a nib body layer 2. The nib outer layer 1 is covered and fixed on the outer surface of the nib body layer 2. The nib body layer surrounds an assembly groove 3. The thickness of the nib outer layer 1 is the same as that of the nib body layer. The thickness ratio of 2 is 1:5.

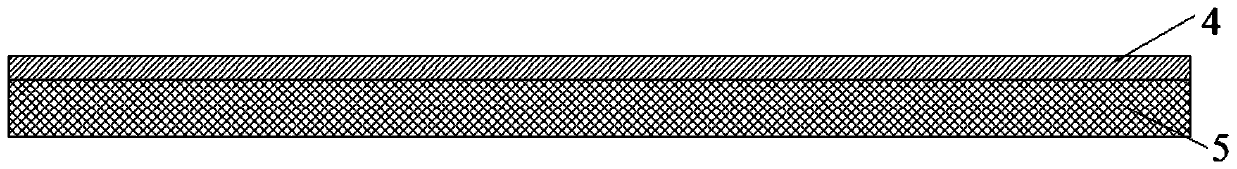

[0042] The nib outer layer 1 includes the following raw materials in parts by weight: 120 parts of the first nib base material silicone rubber, 10 parts of the first conductive filler is a mixture of silver powder and copper powder in a weight ratio of 1:1, and the wear-resistant additive is polytetrafluoroethylene The mixture of PTFE, glass microspheres and light calcium carbonate in a weight ratio of 1:1:1 is 18 parts in total, 1.5 parts of silane coupling agent, 3 parts of plasticizer phthalate, the first dispersant vinyl bis 2 parts stearamide, 5 parts carbon powder, 1 part vulca...

Embodiment 2

[0045] The passive capacitive pen nib of the present embodiment, as figure 1 As shown, it includes a nib outer layer 1 and a nib body layer 2. The nib outer layer 1 is coated and fixed on the outer surface of the nib body layer 2. The nib body layer surrounds an assembly groove 3. The thickness of the nib outer layer 1 is the same as that of the nib body layer. The thickness ratio of 2 is 1:10.

[0046] The outer layer 1 of the nib includes the following raw materials in parts by weight: 130 parts of the first nib base material nitrile rubber, 8 parts of the first conductive filler is a mixture of silver powder and carbon nanotubes at a weight ratio of 20:1, and the wear-resistant additive is tetrafluoroethylene 20 parts of ethylene (PTFE) and glass microspheres in a weight ratio of 1:1, 2 parts of titanate coupling agent, 5 parts of plasticizer aliphatic dibasic acid ester, 4 parts of first dispersant triethylhexyl phosphoric acid , 6 parts of carbon powder, 2 parts of vulca...

Embodiment 3

[0049] The passive capacitive pen nib of the present embodiment, as figure 1 As shown, it includes a nib outer layer 1 and a nib body layer 2. The nib outer layer 1 is coated and fixed on the outer surface of the nib body layer 2. The nib body layer surrounds an assembly groove 3. The thickness of the nib outer layer 1 is the same as that of the nib body layer. The thickness ratio of 2 is 1:8.

[0050] The outer layer 1 of the nib includes the following raw materials in parts by weight: 110 parts of the first nib base material silicone rubber, 12 parts of the first conductive filler is a mixture of silver powder, copper powder and carbon nanotubes in a weight ratio of 20:20:1, wear-resistant The agent is tetrafluoroethylene (PTFE) and light calcium carbonate in a weight ratio of 1:1, a total of 16 parts, plasticizer phthalate 3 parts, silane coupling agent 2.5 parts, the first dispersant fatty acid polyethylene glycol 2.5 parts of alcohol ester, 7 parts of carbon powder, 3 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com