Cover plate ink remover and preparation and use method thereof

A technology of remover and cover plate, which is applied in the direction of remover and coating of chemical paint/ink, which can solve the problems of poor acid solubility, weak removal power, and unsustainable removal effect, and achieve strong industrial application prospects and processing Mild conditions and strong reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A kind of preparation method of cover plate ink remover, take the main agent of formulation amount, penetrating agent, mixed acid accelerator, oxidation accelerator and surfactant in stirring kettle, after stirring evenly, get cover plate ink remover, wherein Stirring time is 30-60 minutes.

[0034] A method for using a cover plate ink remover, the steps are as follows:

[0035] Step 1: Soak the cover ink glass to be treated in the cover ink remover for 3-10 minutes, then take out the cover ink glass after the ink has been peeled off;

[0036] In step 1, the cover ink remover is placed in a constant temperature heating device and heated to 55-65°C, and the cover ink glass is soaked in the heated remover, and at the same time, brushes and roller brushes are used to Clean the glass surface, under the action of external forces such as brushes, the ink removal rate can be improved and the processing time can be shortened; or, in step 1, the cover plate ink remover is place...

Embodiment 1

[0040] 1. Preparation of remover: Weigh 65 parts of N-methylpyrrolidone, 10 parts of ethylene glycol phenyl ether, 8 parts of formic acid, 8 parts of acetic acid, 8 parts of 35wt% hydrogen peroxide and 1 part of OP-10 in a stirred tank, Use a glass rod to fully mix and stir to prepare a uniformly mixed remover;

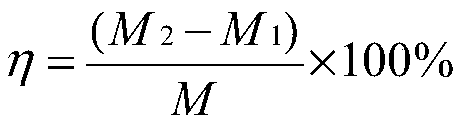

[0041] 2. Ink removal test: cut the cover ink glass into 6cm*4cm samples, pay attention not to scratch the glass during the cutting process, weigh the quality of the glass sample and record it as M 2 (unit g), put the above remover in a 100W ultrasonic instrument, and immerse the cut glass sample in the remover of the ultrasonic instrument for treatment, observe the peeling situation, wash it with pure water and heat it with a hot air after the peeling process is completed Dry, the time of peeling is recorded as T (unit s), weighs the quality of peeling after its peeling again and records as M 1 (unit g);

[0042] 3. Calculation of removal rate η:

[0043]

[00...

Embodiment 2

[0048] 1. Preparation of remover: Weigh 60 parts of N-methylpyrrolidone, 5 parts of ethylene glycol phenyl ether, 5 parts of formic acid, 5 parts of acetic acid, 0.5 part of 35wt% hydrogen peroxide and 0.1 part of OP-10 in a stirred tank, Use a glass rod to fully mix and stir to prepare a uniformly mixed remover;

[0049] 2. Ink removal test: the same as in Example 1;

[0050] 3. the calculation of removal rate η: same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com