Preparation method of cross-linked acid

A technology of cross-linking acid and cross-linking agent, which is applied in chemical instruments and methods, composition of drilling holes, etc., can solve problems such as low reaction rate and low filtration loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

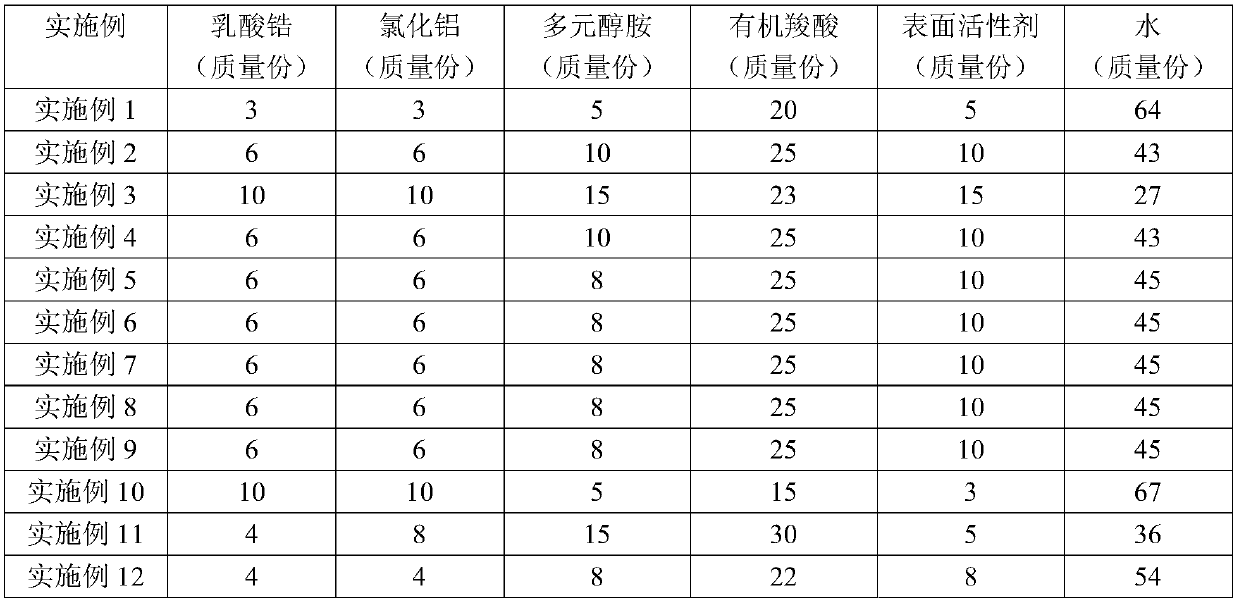

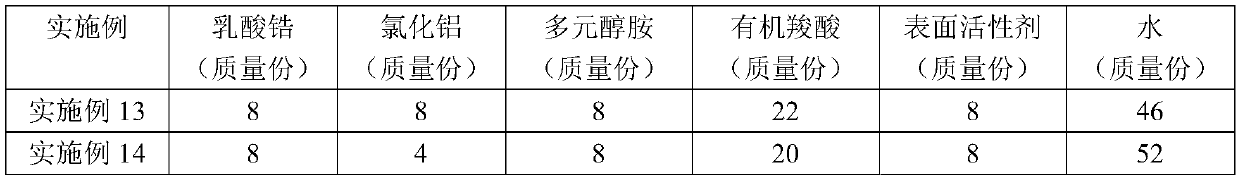

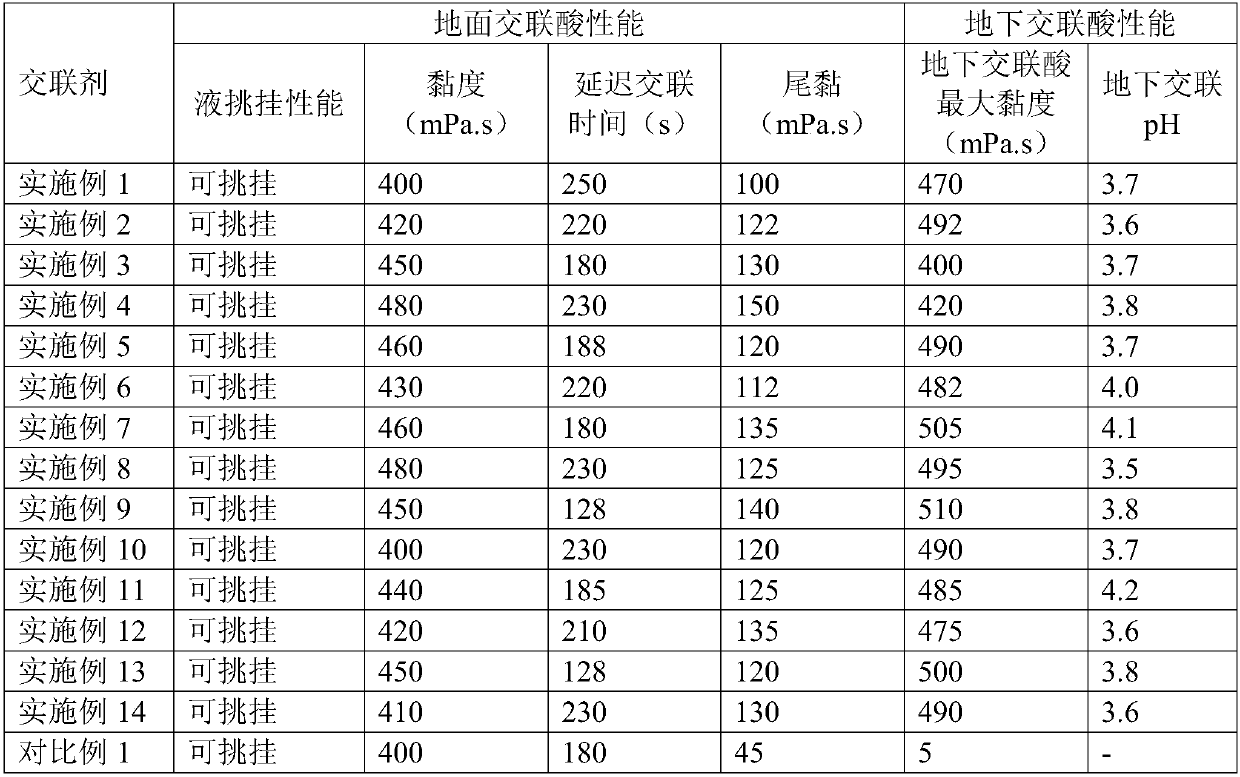

Examples

Embodiment 1

[0075] 1) Add 3 parts by mass of zirconium lactate and 3 parts by mass of aluminum chloride to 64 parts by mass of water, and fully stir and dissolve at 20°C;

[0076] 2) Add 5 parts by mass of triethanolamine and 20 parts by mass of lactic acid in sequence to the solution in step 1), and react at 20°C for 6 hours;

[0077] 3) Add 5 parts by mass of sodium dodecylbenzenesulfonate to the solution in step 2) at 20°C, stir and mix evenly to obtain crosslinking agent 1.

Embodiment 2

[0079] 1) Add 6 parts by mass of zirconium lactate and 6 parts by mass of aluminum chloride to 43 parts by mass of water, and fully stir and dissolve at 30°C;

[0080] 2) Add 10 parts by mass of diethanolamine and 25 parts by mass of citric acid in sequence to the solution in step 1), and react at a constant temperature of 30° C. for 4 hours;

[0081] 3) Add 10 parts by mass of sodium lauryl sulfate to the solution in step 2) at .30°C, stir and mix evenly to obtain crosslinking agent 2.

Embodiment 3

[0083] 1) Add 10 parts by mass of zirconium lactate and 10 parts by mass of aluminum chloride to 27 parts by mass of water, and fully stir and dissolve at 25°C;

[0084] 2) Add 15 parts by mass of triisopropanolamine and 23 parts of oxalic acid in sequence to the solution in step 1), and react at a constant temperature of 25°C for 3 hours;

[0085] 3) Add 15 parts by mass of sodium dodecylsulfonate to the solution in step 2) at 25°C, stir and mix evenly to obtain crosslinking agent 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com