Method for preparing nano silicon through three-stage grinding

A technology of nano-silicon and grinding time, which is applied in the direction of nano-technology, silicon, structural parts, etc., can solve the problems of affecting the connection between active materials and current collectors, reversible capacity depletion, and difficulty in reaching a smaller size, so as to ensure uniform dispersion and stability performance, improve wet grinding efficiency, and reduce nano-silicon particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

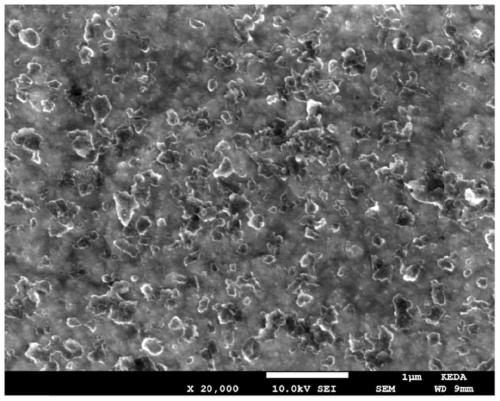

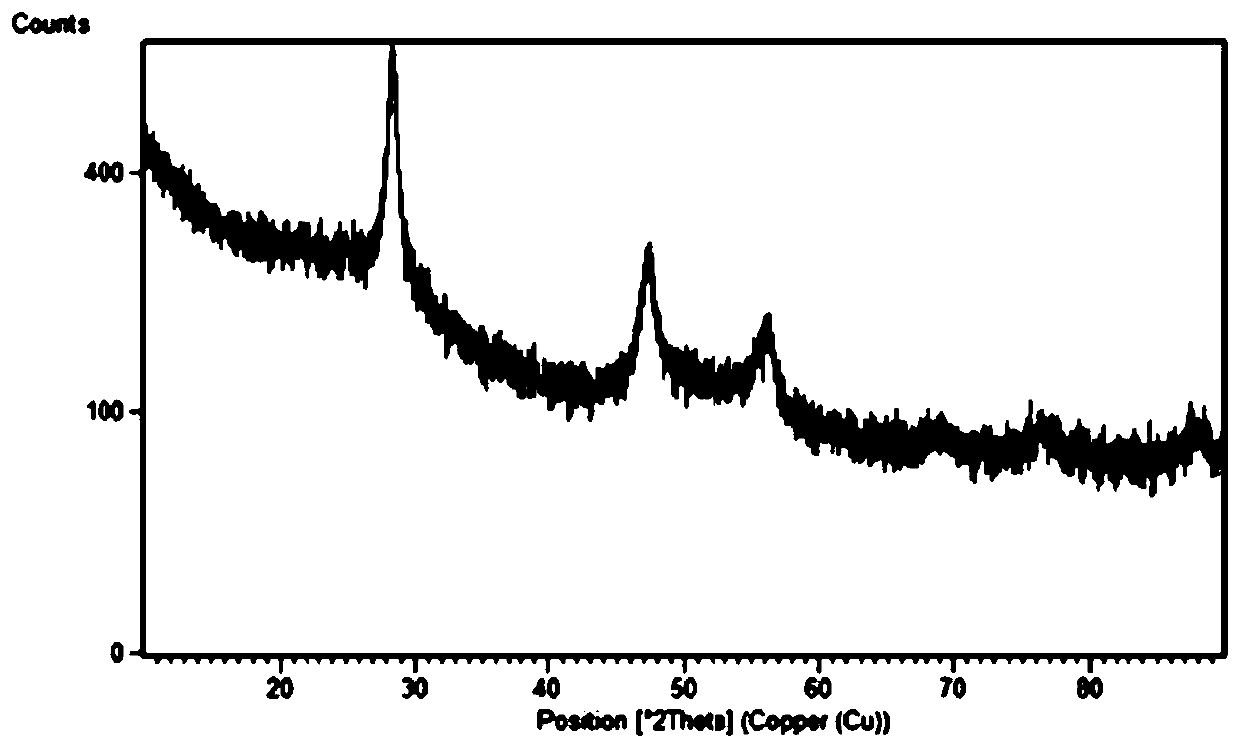

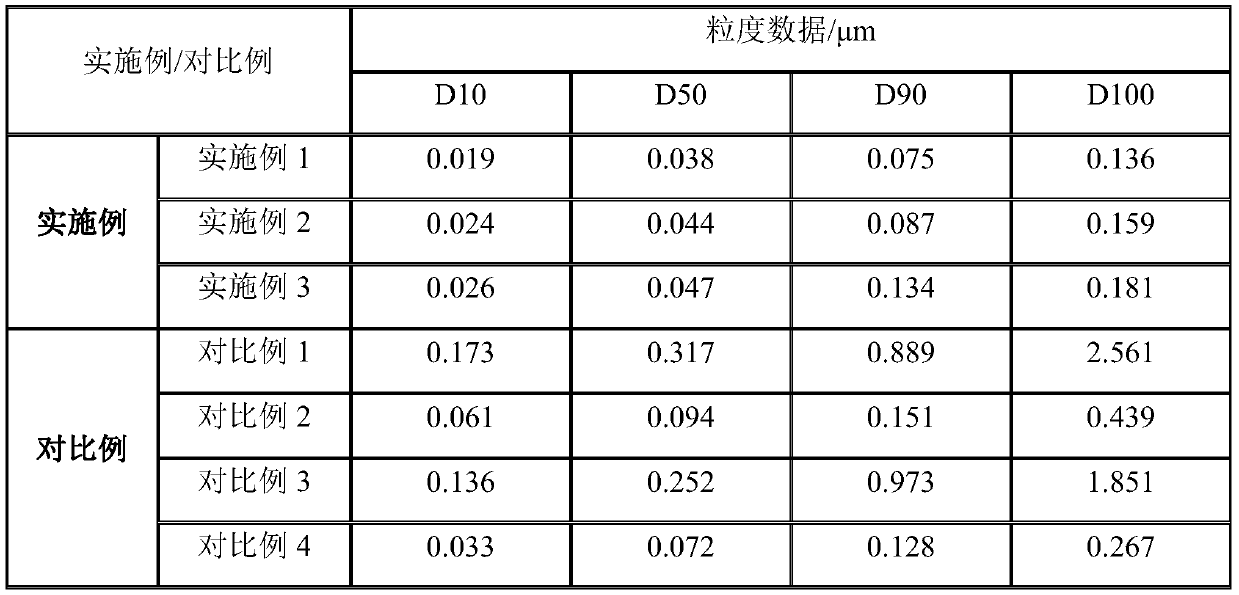

[0023] A method for preparing nano-silicon by three-stage grinding described in this embodiment is specifically carried out according to the following steps:

[0024] 1) Add high-purity silicon powder with a median particle size of 10 μm and a purity of ≥99% into the dispersion tank of a horizontal sand mill, add absolute ethanol to adjust the solid content to 40wt.%, and then add sodium pyrophosphate as a dispersant , wherein the mass ratio of sodium pyrophosphate to silicon powder is 10:100, pre-dispersed; the dispersed mixed solution is introduced into a horizontal sand mill for primary grinding, the line speed of the sand mill is 12m / s, and the zirconia The diameter of the ball is 1 μm, the ball-to-material ratio is 5:1, and the grinding time is 2 hours to obtain a particle size of nano-silicon D50<1000nm;

[0025] 2) Import the slurry after primary grinding into a horizontal sand mill for secondary grinding. The linear speed of the sand mill is 14m / s, the diameter of the ...

Embodiment 2

[0028] A method for preparing nano-silicon by three-stage grinding described in this embodiment is specifically carried out according to the following steps:

[0029] 1) Add high-purity silicon powder with a median particle size of 50 μm and a purity of ≥99% into the dispersion tank of a horizontal sand mill, add methanol to adjust the solid content to 30wt.%, and then add sodium acrylate as a dispersant, of which acrylic acid The mass ratio of sodium to silicon powder is 5:100 for pre-dispersion; the dispersed mixed solution is introduced into a horizontal sand mill for primary grinding, the line speed of the sand mill is 12.5m / s, and the diameter of the stainless steel ball is 5μm, the ball-to-material ratio is 8:1, the grinding time is 5h, and the particle size D50 of nano-silicon is <1000nm;

[0030] 2) Import the slurry after primary grinding into a horizontal sand mill for secondary grinding. The linear speed of the sand mill is 14.5m / s, the diameter of the stainless ste...

Embodiment 3

[0033] A method for preparing nano-silicon by three-stage grinding described in this embodiment is specifically carried out according to the following steps:

[0034] 1) Add high-purity silicon powder with a median particle size of 100 μm and a purity of ≥99% into the dispersion tank of a horizontal sand mill, add acetone to adjust the solid content to 20wt.%, and then add guar gum as a dispersant. The mass ratio of Gur gum to silica powder is 1:100, and the pre-dispersion is carried out; the dispersed mixed solution is introduced into a vertical sand mill for primary grinding, and the line speed of the sand mill is 13m / s. The diameter is 10 μm, the ball-to-material ratio is 10:1, the grinding time is 10 hours, and the particle size D50<1000nm of nano-silicon is obtained;

[0035] 2) Import the slurry after primary grinding into a vertical sand mill for secondary grinding. Time 30h, obtain nano-silicon particle size D50<100nm;

[0036] 3) Import the slurry after the secondar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com