Method for preparing aluminum battery positive electrode material by using MOF induced metal selenide

A technology of metal selenides and induced metals, applied in the direction of metal selenides/tellurides, battery electrodes, active material electrodes, etc., can solve the problems of structural collapse, easy dissolution, etc., and achieve the effect of increasing intercalation and extraction, and excellent energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

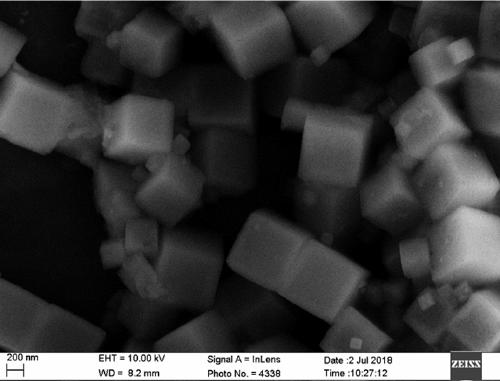

[0030] 1. Dissolve 1 mmol of zinc nitrate in 30 mL of methanol solution, and obtain solution A under strong magnetic stirring; dissolve 10 mmol of 1-methylimidazole in 10 mL of methanol solution, and under strong magnetic stirring, Solution B was obtained; then solutions A and B were thoroughly mixed, stirred and left to stand for 12 h. Then it was centrifuged and washed three times with deionized water and absolute ethanol, and finally it was dried in a vacuum oven at 80 °C to obtain the MOF-induced ZnSe precursor. Its scanning electron microscope picture is as figure 1 shown.

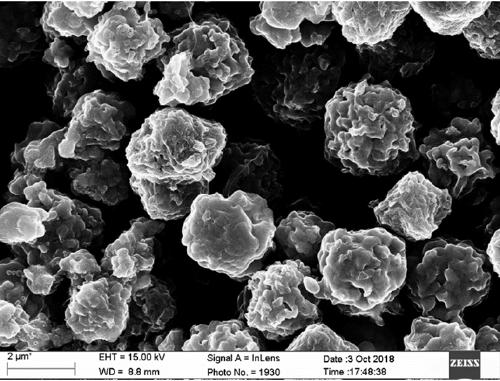

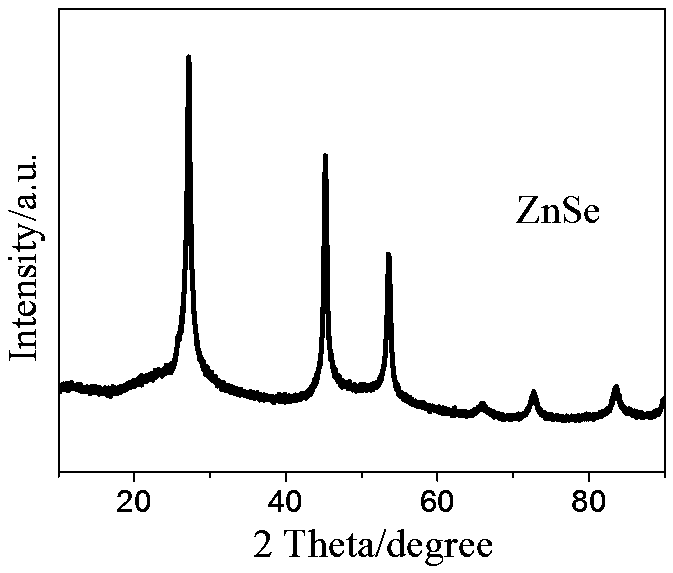

[0031] 2. Fully grind the MOF-induced ZnSe precursor and selenium powder in a mortar according to the mass ratio of 1:2 to make it evenly mixed, and then put the mixture under N 2 Calcined at 300 °C for 2 h in a protective atmosphere. Finally, cool down to room temperature with the furnace to obtain a black solid powder, which is the target product ZnSe active material. Its scanning electron micro...

Embodiment 2

[0035] 1. Dissolve 1 mmol of cobalt nitrate in 30 mL of methanol solution, and obtain solution A under strong magnetic stirring; dissolve 10 mmol of 1-methylimidazole in 30 mL of methanol solution, and under strong magnetic stirring, Solution B was obtained; finally, solutions A and B were fully mixed, stirred and allowed to stand for 24h. Then it was centrifuged and washed three times with deionized water and absolute ethanol, and finally dried in a vacuum oven at 80 °C to obtain MOF-induced CoSe 2 Precursor. Its scanning electron microscope picture is as Image 6 shown.

[0036] 2. CoSe induced by MOF 2 Precursor and selenium powder are fully ground in mortar according to mass ratio 1:2, make it mix evenly, then its mixture is in N 2 Calcined at 500 °C for 3 h in a protective atmosphere. Finally, cool down to room temperature with the furnace to obtain a black solid powder as the target product CoSe 2 active material. Its scanning electron microscope picture is as F...

Embodiment 3

[0040]1. Dissolve 1 mmol of copper nitrate in 40 mL of methanol solution, and obtain solution A under strong magnetic stirring; dissolve 10 mmol of 2-methylimidazole in 30 mL of methanol solution, and under strong magnetic stirring, Solution B was obtained; finally, solutions A and B were thoroughly mixed, stirred and allowed to stand for 12 h. Then it was centrifuged and washed three times with deionized water and absolute ethanol, and finally it was dried in a vacuum oven at 80 °C to obtain the MOF-induced CuSe precursor.

[0041] 2. Fully grind the MOF-induced CuSe precursor and selenium powder in a mortar according to the mass ratio of 1:1 to make them evenly mixed, and then put the mixture in N 2 Calcined at 400 °C for 2 h in a protective atmosphere. Finally, cool down to room temperature with the furnace to obtain a black solid powder, which is the target product CuSe active material.

[0042] 3. Mix CuSe active material, carbon black and polytetrafluoroethylene binder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com