Antibacterial piezoelectric Mxene composite material and application thereof

A composite material and piezoelectric material technology, applied in medical science, tissue regeneration, prosthesis, etc., can solve problems such as elastic modulus mismatch, poor biocompatibility, dimensional instability, etc., and achieve mild synthesis conditions and porosity. The effect of promoting proliferation, differentiation and cell adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

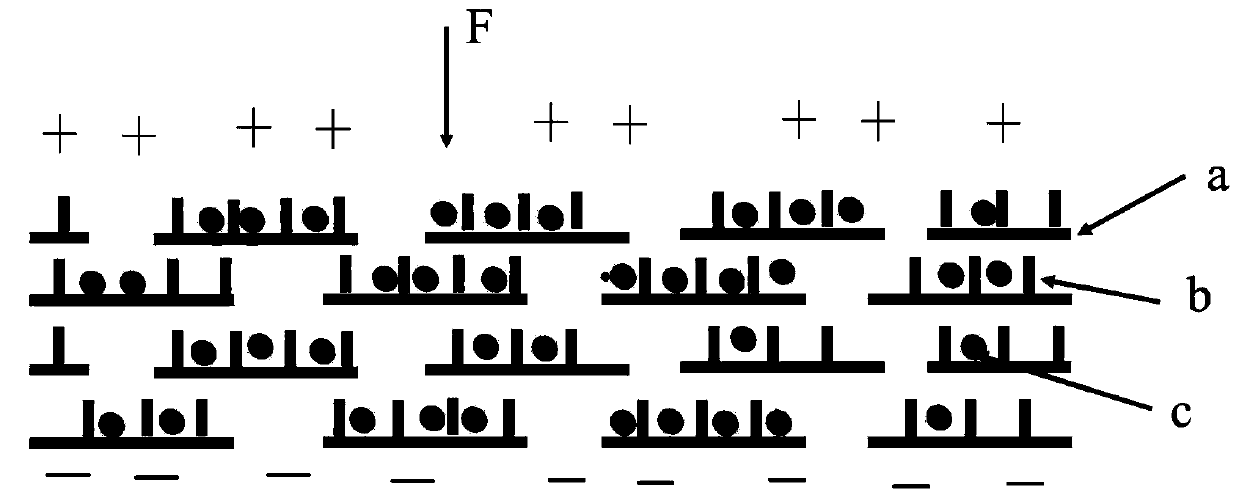

Image

Examples

Embodiment 1

[0025] 1. Preparation: 1g of Ti 3 C 2 Add 1g sodium potassium lithium niobate (particle size is 20nm) and carry out hydrothermal reaction at 40°C for 5h, on Ti 3 C 2 In situ polymerization to obtain nanometer sodium potassium lithium niobate, after separation and purification, soak in 200mL of 1.5mol / L doxorubicin DMF solution for 3h, wash with 95% absolute ethanol three times, and then wash with acetone solution Three times, vacuum drying at 40 °C to obtain Ti 3 C 2 composite material.

[0026] 2. Performance test: obtained Ti 3 C 2 Composite materials due to nano-Na-K-Li piezoelectric material and Ti 3 C 2 Co-doped materials to exert their respective properties, so as to have antibacterial and piezoelectric properties at the same time. With antibacterial piezoelectric Ti 3 C 2 The composite material is cultured with somatic osteoblasts under the action of external stress to increase the concentration of cells on the surface by 30.5%, and the drug release of doxoru...

Embodiment 2

[0029] 1. Preparation: 0.5 g of Ta 4 C 3 Add 10g lithium niobate (particle size is 25nm), in Ta 4 C 3 In situ polymerization to obtain nano-lithium niobate, after separation and purification, soak in 150mL of 2.5mol / L quinolone in dichloromethane solution for 4.5h, rinse with 95% absolute ethanol three times, and then wash three times with acetone solution , vacuum-dried at 40°C, the antibacterial piezoelectric Ta 4 C 3 composite material.

[0030] 2. Performance test: the obtained piezoelectric Ta with antibacterial properties 4 C 3 The composite material is cultured with somatic osteoblasts under stress to increase the concentration of cell proliferation and differentiation on the surface by 35.8%. The release of quinolone drugs is stable and long-lasting, and the content of 55.3% can still be maintained after 30 hours of continuous release.

Embodiment 3

[0032] 1. Preparation: 0.1 g of Nb was prepared by co-precipitation 4 C 3 Add 10g potassium niobate (particle size is 40nm), in Nb 4 C 3 Nano potassium niobate was obtained by in-situ polymerization. After separation and purification, soak in 250 mL of 1mol / L penicillin phosphate buffer for 5 hours, wash with 95% absolute ethanol three times, and then wash with acetone solution for three times. Vacuum at 40°C dried to produce piezoelectric Nb with antimicrobial properties 4 C 3 composite material.

[0033] 2. Performance test: the obtained piezoelectric Nb with antibacterial properties 4 C 3 The composite material is cultured with somatic osteoblasts under stress to increase the concentration of cell proliferation and differentiation on the surface by 22.6%, and the release of penicillin is stable and long-lasting, and the content of 33.6% can still be maintained after 36 hours of continuous release.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com