Epoxy resin based on vanillin and amino acid, and preparation method and application thereof

A technology for epoxy resin preparation and epoxy resin, which is applied in epoxy resin coatings, imino compound preparation, thiol preparation and other directions, can solve problems such as poor degradability and environmental pollution, achieve excellent mechanical properties and water resistance, Simple process and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A kind of preparation method based on the epoxy resin of vanillin and amino acid, comprises the steps:

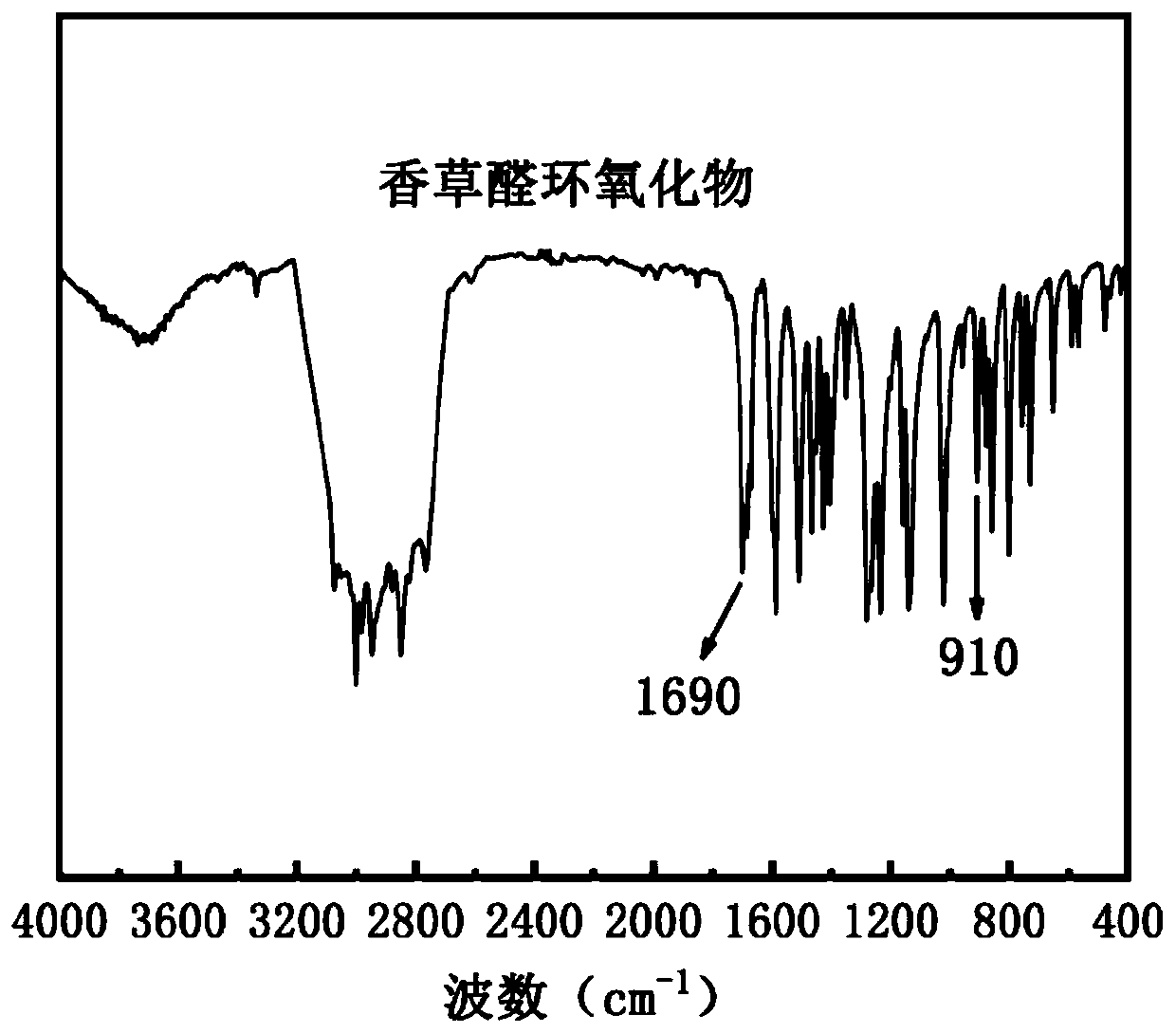

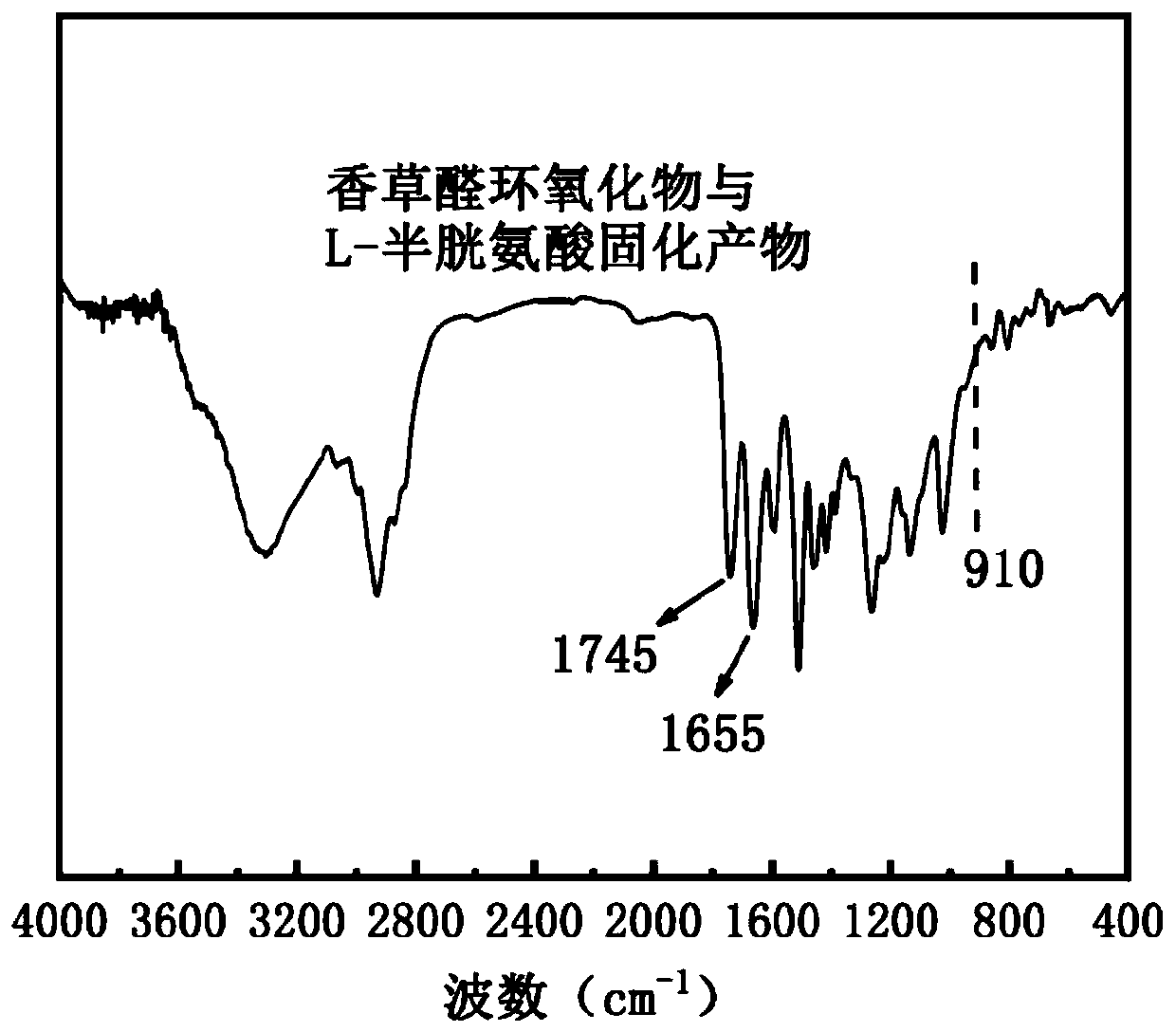

[0044]1) Synthesis of vanillinyl glycidyl ether: In terms of mass fraction, 1 part of benzyltriethylammonium chloride, 20 parts of vanillin, and 50 parts of epichlorohydrin were mixed, heated to 80 ° C for 2 hours, and then vacuum Suck off excess epichlorohydrin. After the epichlorohydrin is extracted, cool the reactant to 30°C, add 35 parts of 40% sodium hydroxide solution dropwise within 0.5h, and add 35 parts of water 10 minutes after the completion of the dropwise addition to dilute. After the addition was complete, the reaction was continued under these conditions for 1 h. After the reaction was completed, the product was filtered and washed 3 times with pure water. 19.3 parts of vanillinyl glycidyl ether were obtained, the yield was about 72%. The infrared spectrum of vanillin glycidyl ether is as follows figure 1 As shown, visible at 1690cm -1 There are o...

Embodiment 2

[0050] Solidify vanillin glycidyl ether and lysine in Example 1: Dissolve 2 parts of vanillin glycidyl ether in 2 parts of propylene glycol methyl ether in mass fraction, and then add 3.0 parts of lysine 50% alkaline aqueous solution (dissolved by adjusting the pH with triethylamine), heating the mixed system at 60°C for 2 hours to obtain a homogeneous solution system of the prepolymer, which can be used as a water-solvent resin.

[0051] Coat the above prepolymer solution on the tinplate, then enter the oven at 80°C / 2h, 100°C / 2h for drying and high-temperature curing treatment, and obtain a yellow transparent film after curing, with a dry film thickness of 20-30μm.

Embodiment 3

[0053] Solidify vanillin glycidyl ether and lysine in Example 1: Dissolve 2 parts of vanillin glycidyl ether in 2 parts of isopropanol in terms of mass fraction, and then add 1.5 parts of lysine 50% alkaline aqueous solution (adjust the pH by triethylamine to dissolve it) and 0.25 parts of diethylenetriamine, heat the mixed system at 50°C for 3 hours to obtain a homogeneous solution system of the prepolymer, which can be used as a water-solvent resin .

[0054] Coat the above prepolymer solution on the tinplate, then enter the oven at 80°C / 2h, 120°C / 2h for drying and high-temperature curing treatment, and obtain a yellow transparent film after curing, with a dry film thickness of 20-30μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com