Hydroxypropyl methyl cellulose-based aroma sustained-release material and preparation method thereof, composite sheet and preparation method thereof, and application of hydroxypropyl methyl cellulose-based aroma sustained-release material and composite sheet in heat-not-burning tobacco products

A hydroxypropyl methylcellulose, heat-not-burn technology, applied in tobacco, application, treatment of tobacco and other directions, can solve the problems of limited technical means, slow and uniform release of flavors and fragrances, and inability to crack flavor substances, and achieves various application forms. , The effect of easy process realization and simple manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

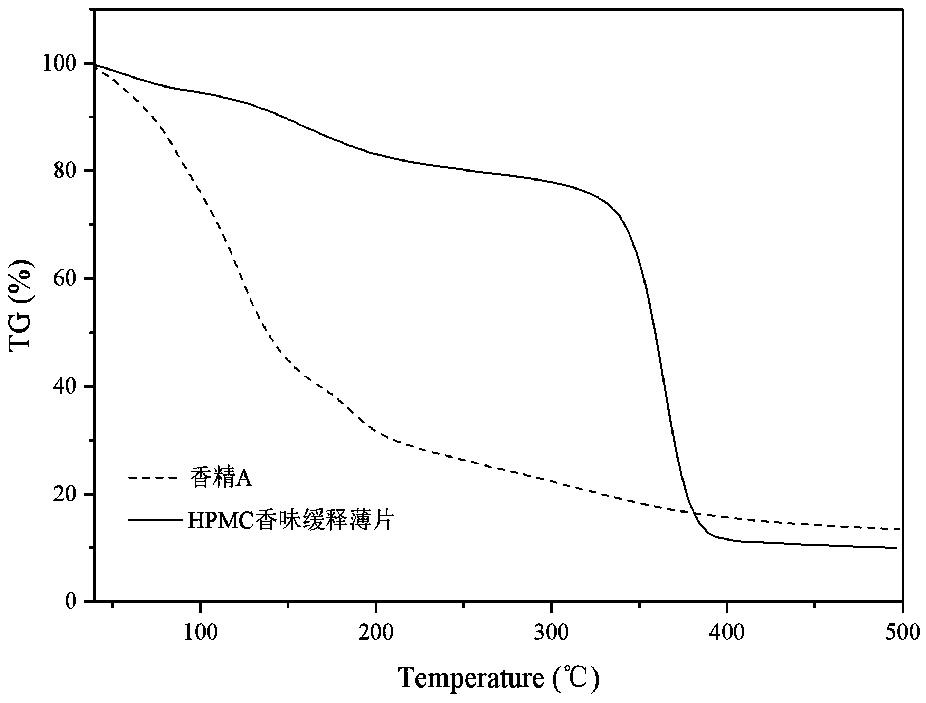

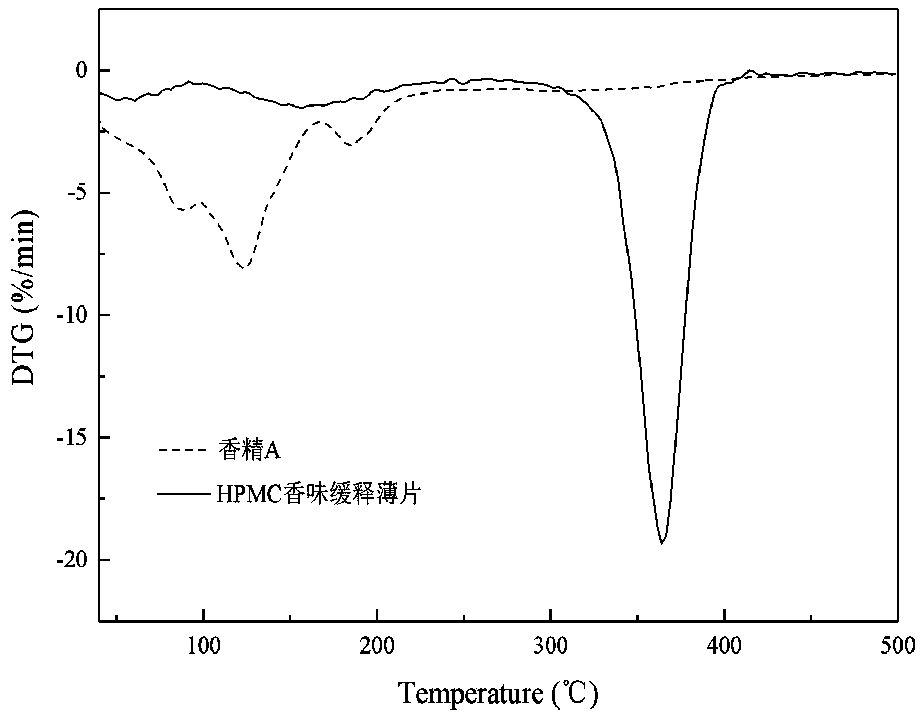

[0066] Flavor A is a commonly used cigarette flavor, which contains some common volatile and semi-volatile flavor components, mainly including: water, ethyl butyrate, ethyl 2-methyl butyrate, ethyl isovalerate, furfural, Hexyl caproate, 3-methyl-pyrazine, 2-ethyl-3-methylpyrazine, benzaldehyde, acetophenone, macrostigmatrienone, geranylacetone, β-damascenone, di Hydrodamascone, menthol, methyl phenylacetate, tobacco extract, fig extract, apple extract, jujube tincture, vanilla bean tincture, benzoin balm, licorice liquid extract, etc.

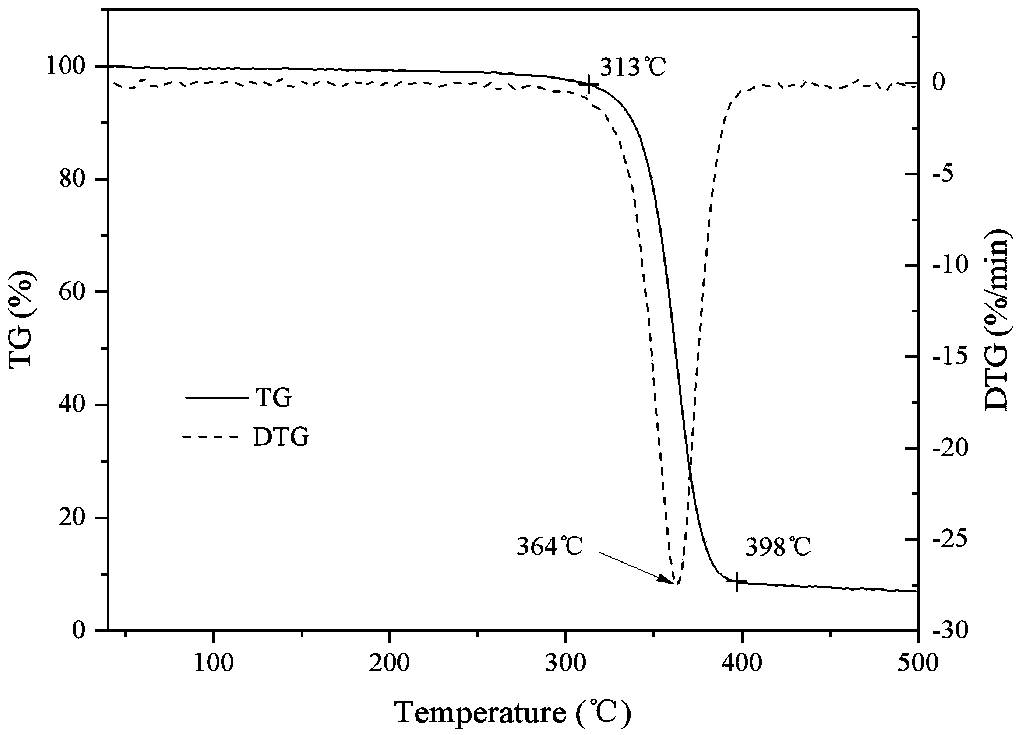

[0067] In order to promote the slow and uniform release of flavor A during the heating stage, this solution uses hydroxypropyl methylcellulose as a sheet substrate to fix flavor A and applies it to the heating end of the heat-not-burn tobacco product. The specific implementation method is as follows: Weigh 4g of hydroxypropyl methylcellulose (food grade, produced in India), and add about 30ml of water to completely dissolve the hydroxypropylmet...

Embodiment 2

[0076] Another optimized implementation is to use an adsorbent to absorb flavors and fragrances, then add hydroxypropyl methylcellulose solution to make flavor slow-release sheets, and apply them to the heating end of heat-not-burn tobacco products. The specific steps are as follows: take the activated The final diatomite is passed through a 40-mesh sieve, dried in an oven at 500°C for 12 hours, and cooled at room temperature for later use; mix essence A with 40-mesh diatomaceous earth at a ratio of 2:1, stir well, and then add an appropriate amount of hydroxypropyl methyl Base cellulose (the ratio of the three is 2:1:4), add about 10 times the volume of water to dissolve the hydroxypropyl methylcellulose to form a viscous liquid, stir well until the absorbent and flavors and fragrances are evenly dispersed; The above liquid is evenly coated on a flat plate, and the solvent is removed by drying with hot air at 30°C to obtain a thin sheet with a thickness of about 0.5mm; it is c...

Embodiment 3

[0079]Hydroxypropyl methylcellulose was used as substrate to immobilize fragrance A, and cyclodextrin was added as adsorbent. The specific implementation steps are as follows: Weigh 1g of cyclodextrin, mix it with 2g of essence A, and equilibrate at room temperature for 0.5h; then add 4g of hydroxypropyl methylcellulose, dissolve it with about 40ml of water to form a viscous liquid, and stir it fully to make it Disperse evenly; apply the above liquid on a flat plate, remove the solvent by evaporating at room temperature, and obtain a thin-film sustained-release composite material with a thickness of about 0.5mm; cut the thin slice and blend it into heat-not-burn tobacco products at a ratio of 2% in tobacco materials.

[0080] The test results show that the hydroxypropyl methylcellulose flavor sustained-release sheet added with cyclodextrin can significantly improve the uniformity of flavor and fragrance release in heat-not-burn tobacco products, which is beneficial to the flav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com