Method for detecting performance of hydrogen sulfide absorption and elimination solution

A hydrogen sulfide and performance technology, which is applied in the field of detection of hydrogen sulfide absorption and elimination liquid, can solve the problems of poor quantitative degree, no independent gas distribution and detection function, etc., and achieve the effect of simple experimental operation and good repeatability of measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

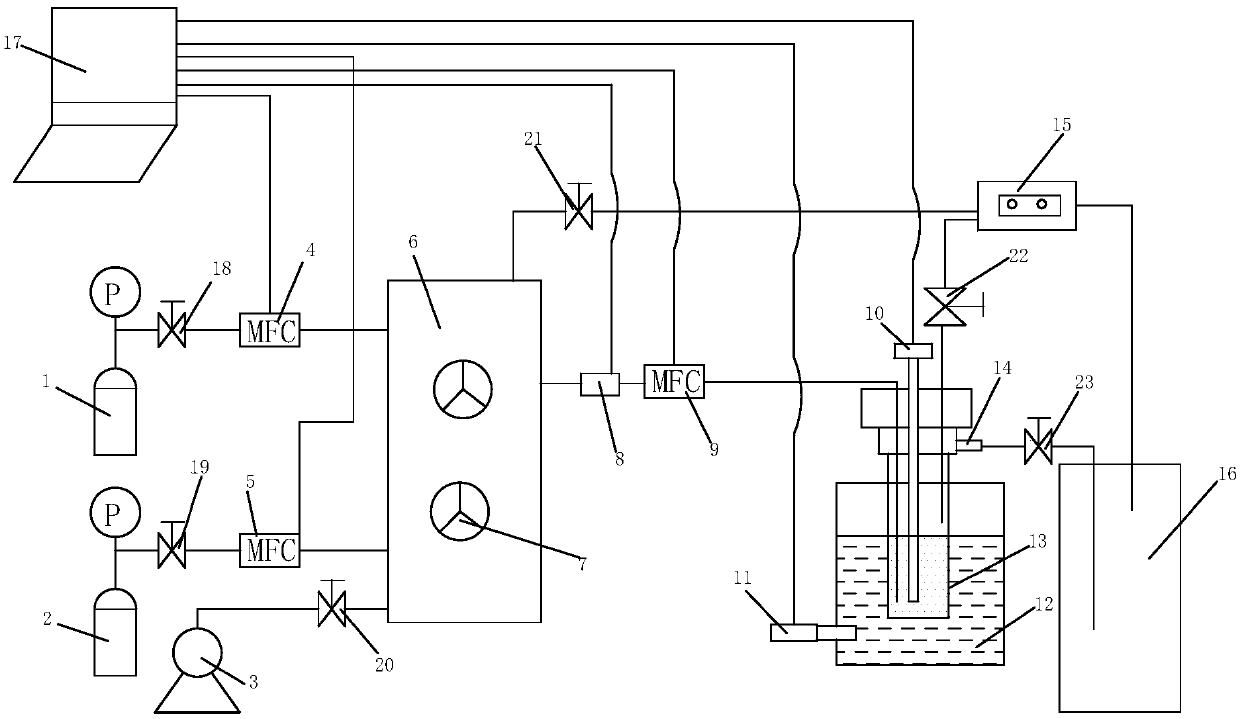

[0050] The high concentration hydrogen sulfide gas used in the experiment is 50000mg / m 3 , the test hydrogen sulfide absorption liquid is a mass fraction of 1.0% sodium carbonate aqueous solution.

[0051] By adjusting the first gas mass flow controller 4 and the second gas mass flow controller 5, using high-pressure nitrogen and 50000mg / m3

[0052] The high-concentration hydrogen sulfide gas is prepared in the gas distribution box 6 to 10000mg / m 3 Hydrogen sulfide gas environment, adjust solenoid valve 8 so that the outlet flow is 0.1L / min, dress 1.0% sodium carbonate aqueous solution 10ml in the reaction tube 13, the concentration of the gas outlet pipe 14 of the reaction tube 13 reaches 500mg / m 3 The time required is 15s.

Embodiment 2

[0054] The high concentration hydrogen sulfide gas used in the experiment is 50000mg / m 3 , The test hydrogen sulfide absorption solution is 3.0% sodium carbonate aqueous solution.

[0055] By adjusting the first gas mass flow controller 4 and the second gas mass flow controller 5, using high-pressure nitrogen and 50000mg / m 3 The high-concentration hydrogen sulfide gas is prepared in the gas distribution box 6 to 10000mg / m 3 Hydrogen sulfide gas environment, adjust solenoid valve 8 so that the outlet flow is 0.1L / min, dress 3.0% sodium carbonate aqueous solution 10ml in reaction tube 13, the concentration of the gas outlet pipe 14 of reaction tube 13 reaches 500mg / m 3 The time required is 36s.

Embodiment 3

[0057] The high concentration hydrogen sulfide gas used in the experiment is 50000mg / m 3 , The test hydrogen sulfide absorption liquid is 30% ethanolamine aqueous solution.

[0058] Through nitrogen mass flow controller and hydrogen sulfide mass flow controller, using nitrogen and 50000mg / m 3 The high-concentration hydrogen sulfide gas is prepared in the gas distribution box 6 to 10000mg / m 3 Hydrogen sulfide gas environment, the electromagnetic valve 8 is adjusted so that the outlet flow is 0.1L / min, the volume of the 30% ethanolamine aqueous solution in the reaction tube 13 is 10ml, and the concentration of the gas outlet pipe 14 of the reaction tube 13 reaches 500mg / m 3 The time required is 973s.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap