Preparation method of HAP/PLA composition bone repair stent loaded with strontium ranelate

A technology of strontium ranelate and composite materials, which is applied in the field of preparation of scaffold materials for bone repair, can solve the problems such as extruded PLA wires, which are rarely reported, and achieve high hardness, good antibacterial properties, and the effect of inhibiting bone resorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of a HAP / PLA composite material bone repair support loaded with strontium ranelate is carried out as follows:

[0024] 1) Fully mix nano-scale hydroxyapatite powder, medical-grade PLA plastic particles and strontium ranelate powder to obtain a mixed raw material; in the mixed raw material, nano-sized hydroxyapatite powder, medical-grade PLA plastic, and strontium ranelate powder The mass ratio of the mixture is 10:90:1; nano-sized hydroxyapatite powder and strontium ranelate powder are respectively passed through a 200-mesh sieve before mixing. The medical grade PLA particles are preferably L-polylactic acid particles. The raw materials were added to the internal mixer and mixed for 15 minutes at 200°C.

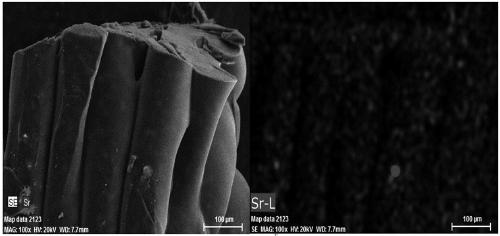

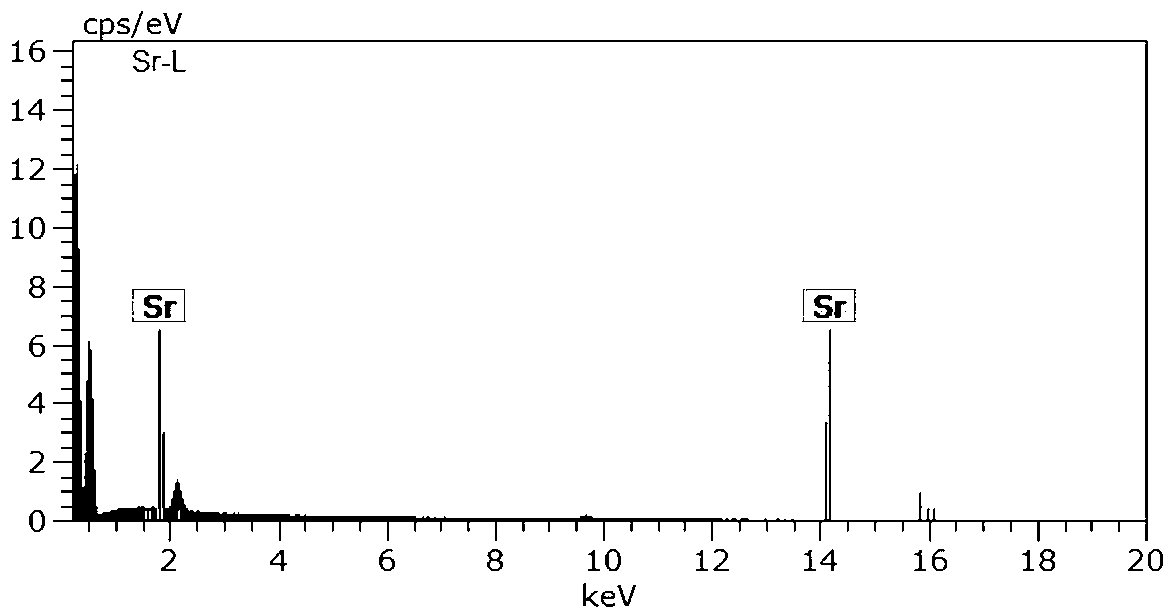

[0025] 2) Melt and extrude the mixed raw materials into wires through a single-screw extruder to obtain HAP / PLA wires doped with strontium ranelate for 3D printing. The diameter of the wires is controlled at 1.75mm; the single-screw extruder The ...

Embodiment 2

[0029] A preparation method of a HAP / PLA composite material bone repair support loaded with strontium ranelate is carried out as follows:

[0030] 1) Fully mix nano-scale hydroxyapatite powder, medical-grade PLA plastic particles and strontium ranelate powder to obtain a mixed raw material; in the mixed raw material, nano-sized hydroxyapatite powder, medical-grade PLA plastic, and strontium ranelate powder The mass ratio of the mixture is 9:92:1; nano-sized hydroxyapatite powder and strontium ranelate powder are respectively passed through a 200-mesh sieve before mixing.

[0031] 2) Melted and extruded into filaments by a single-screw extruder to obtain HAP / PLA wires doped with strontium ranelate for 3D printing, the diameter of the wires is controlled at 1.70-1.80mm; the melting temperature of the single-screw extruder 180~190℃.

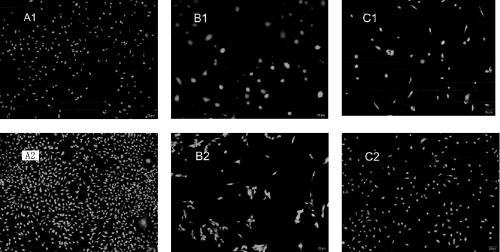

[0032] 3) On the FDM fusion printer, after importing the designed three-dimensional model of the bone repair scaffold, print with the wire obtaine...

Embodiment 3

[0035] A preparation method of a HAP / PLA composite material bone repair support loaded with strontium ranelate is carried out as follows:

[0036] 1) Fully mix nano-scale hydroxyapatite powder, medical-grade PLA plastic particles and strontium ranelate powder to obtain a mixed raw material; in the mixed raw material, nano-sized hydroxyapatite powder, medical-grade PLA plastic, and strontium ranelate powder The mass ratio of the mixture is 11:88:1; nano-sized hydroxyapatite powder and strontium ranelate powder are respectively passed through a 200-mesh sieve before mixing.

[0037] 2) Melted and extruded into filaments by a single-screw extruder to obtain HAP / PLA wires doped with strontium ranelate for 3D printing. The diameter of the wires is controlled at 1.70-1.75mm; the melting temperature of the single-screw extruder is 180°C.

[0038] 3) On the FDM fusion printer, after importing the designed three-dimensional model of the bone repair scaffold, print with the wire obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com