Method and device for continuously preparing heptafluoroisobutyramide

A technology of heptafluoroisobutyramide and heptafluoroisobutyryl, which is applied in the field of preparation of heptafluoroisobutyramide, can solve the problems of complex post-processing, difficult process, high price, etc., and achieve easy industrial production and shorten the process flow , The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

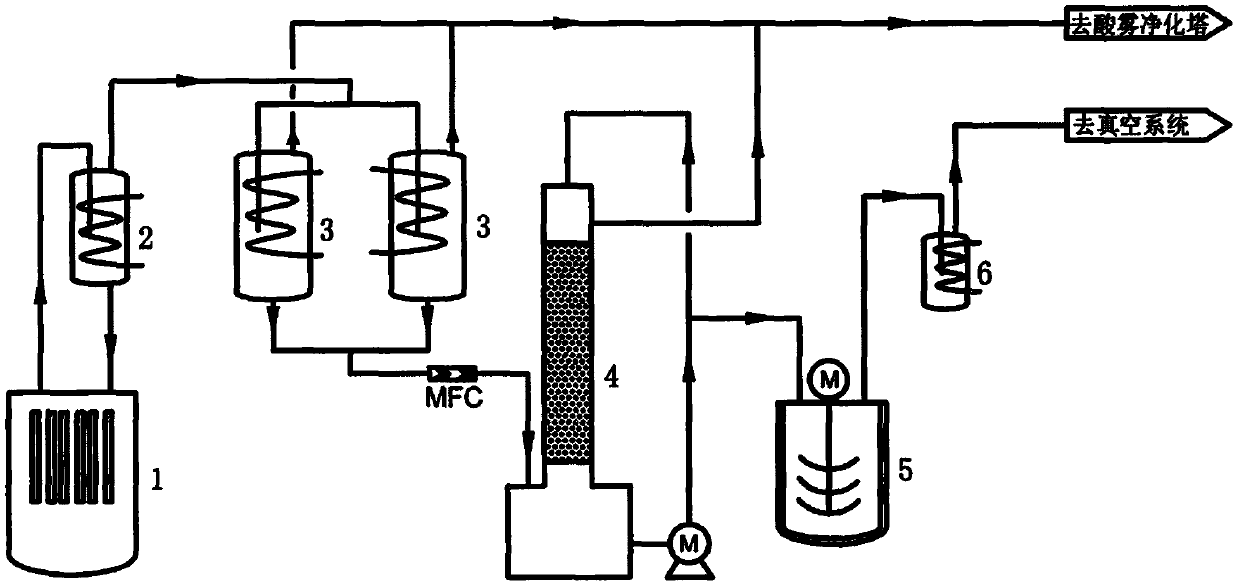

[0027] Such as figure 1 Shown, a kind of device that the method for continuously preparing heptafluoroisobutyramide uses comprises electrolytic kettle (1), condensation reflux device (2), catcher (3), spray tower (4), still ( 5), distillation condenser (6); the electrolytic kettle (1) is connected to the condensing reflux (2), the top of the trap (3) is connected to the top of the condensing reflux (2), and the bottom of the trap (3) is connected to the spray The bottom of the tower (4), and the top of the spray tower (4) are connected to the distillation kettle (5), and the spray tower (4) realizes material circulation through a delivery pump, and a distillation condenser (6) is connected to the distillation kettle (5); The vacuum system is externally connected to the device (6); the trap (3), the spray tower (4), and the distillation condenser (6) all have vent pipelines leading to the acid mist purification tower; two traps are connected in parallel.

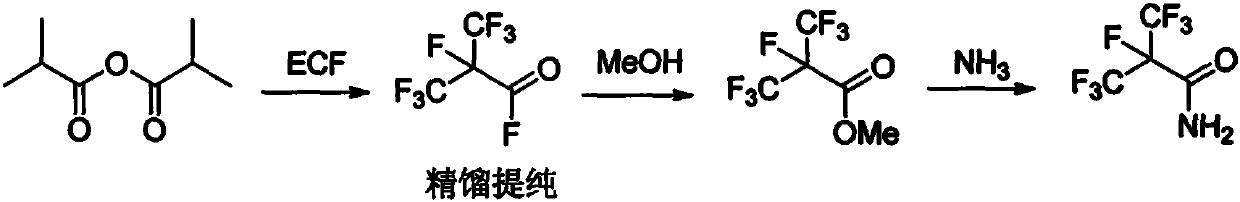

[0028] Use isobutyri...

Embodiment 2

[0030] Use isobutyric anhydride and hydrogen fluoride as raw materials, control the electrolysis voltage to 4.0-8.0V, and the current density to 5-50mA / cm 2 , electrolysis under steady flow conditions. During the electrolysis process, the condensing temperature is controlled at 10-15°C, and the trap temperature is -15--10°C. After the heptafluoroisobutyryl fluoride in the trap reaches a predetermined weight, the trap is switched to ensure the normal operation of the electrolysis; The temperature in the washing tower is 35-45°C, add an amine methanol solution with a concentration of 10mol / L, and start the circular spraying; control the flow rate of heptafluoroisobutyryl fluoride to enter the spray tower at a flow rate of 100-250g / min, After the addition of isobutyryl fluoride, stop spraying; transfer the reaction solution to a vacuum distillation kettle, under stirring, control the temperature of the kettle to 50°C, vacuum degree of 0.09MPa, remove the solvent by distillation u...

Embodiment 3

[0032] Use isobutyric anhydride and hydrogen fluoride as raw materials, control the electrolysis voltage to 4.0-8.0V, and the current density to 5-50mA / cm 2 , electrolysis under steady flow conditions. During the electrolysis process, the condensation temperature is controlled at -80~-60°C, and the trap temperature is -150~-192°C. After the heptafluoroisobutyryl fluoride in the trap reaches the predetermined weight, switch the trap to ensure the normal operation of the electrolysis ;Control the temperature in the washing tower to 0-35°C, add amine-methanol solution with a concentration of 3mol / L, and start the circular spraying; control the flow rate of acyl fluoride to enter the spray tower at a flow rate of 400-500g / min, and wait for the addition of acyl fluoride to be completed , stop spraying; transfer the reaction solution to a vacuum distillation kettle, under stirring, control the temperature of the kettle at 60°C, vacuum degree 0.085MPa, remove the solvent by distillat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com